Descriptions of the PLC subroutines

3.24 Subroutine 51 - Turret1_HED_T (turret with Hall effect device position sensor)

PLC Subroutines Manual

58 Operating Instructions, 12/2012, 6FC5397-2EP10-0BA0

Assigned global variables

None

Relevant PLC machine data

None

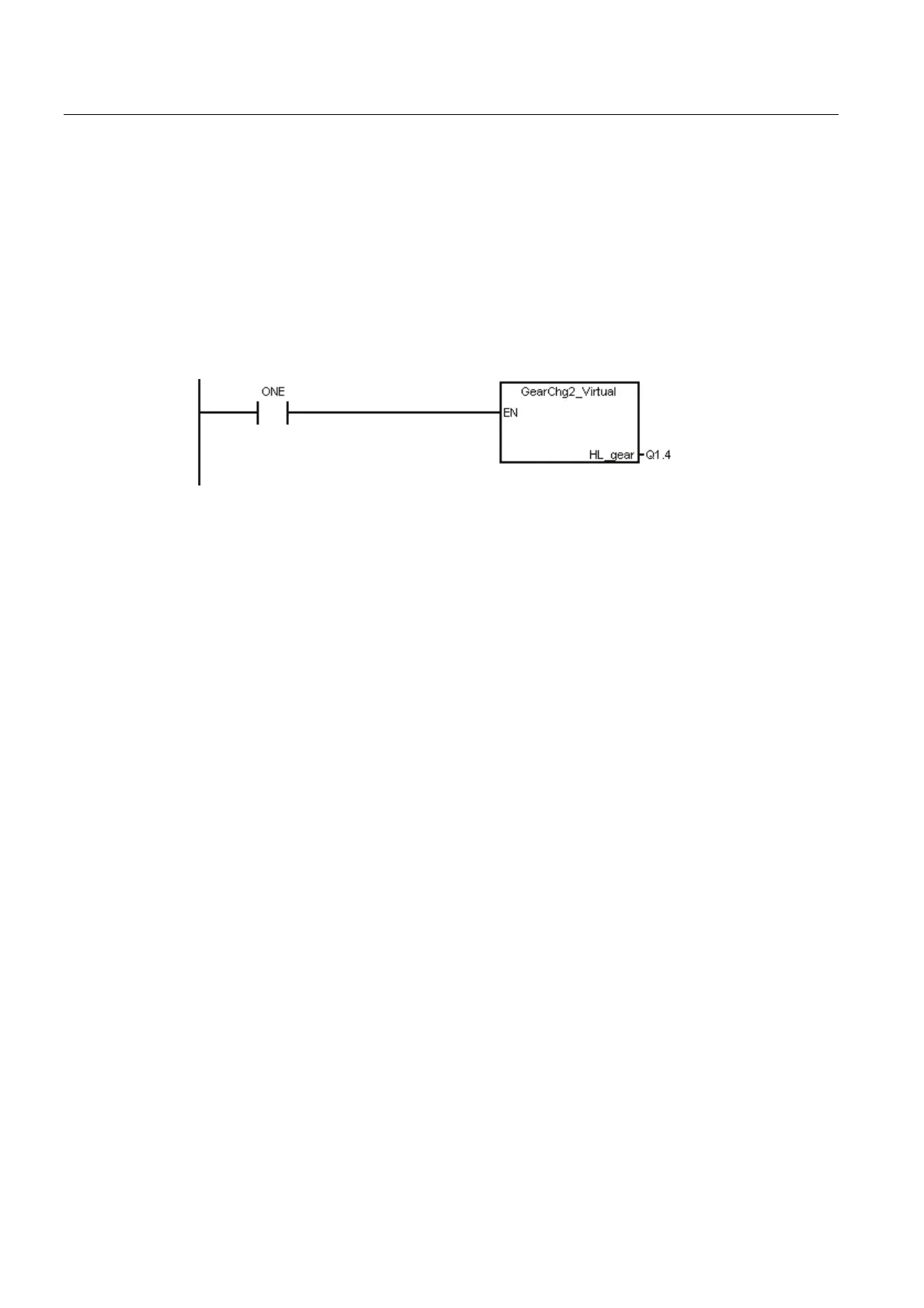

Example for calling subroutine 50

3.24 Subroutine 51 - Turret1_HED_T (turret with Hall effect device

position sensor)

Purpose

Subroutine 51 is used to control the turret with a Hall effect device positioning sensor, and

the turret motor is controlled by the PLC.

The turret rotates clockwise to search for a tool, and rotates counter-clockwise after

positioning the desired tool to clamp it (the turret CCW rotation time can be adjusted). An

alarm occurs if the turret fails to position the desired tool after the duration expires. The

subroutine verifies the time that the turret rotates CCW, and sets a limit of maximum 3

seconds for this rotation time to prevent the turret motor from being broken.

In the AUTO and MDA modes, the T function starts a tool change operation. In the JOG

mode, a short strike on the MCP key changes a turret position.

During a tool change, the NC interface signals "Read-in disable" (DB3200.DBX6.1) and

"Feedhold" (DB3200.DBX6.0) are set; this means that the part program can only continue to

run after the tool change.

The turret positioning is prohibited in the case of an Emergency Stop, turret motor overload

or program test/simulation.

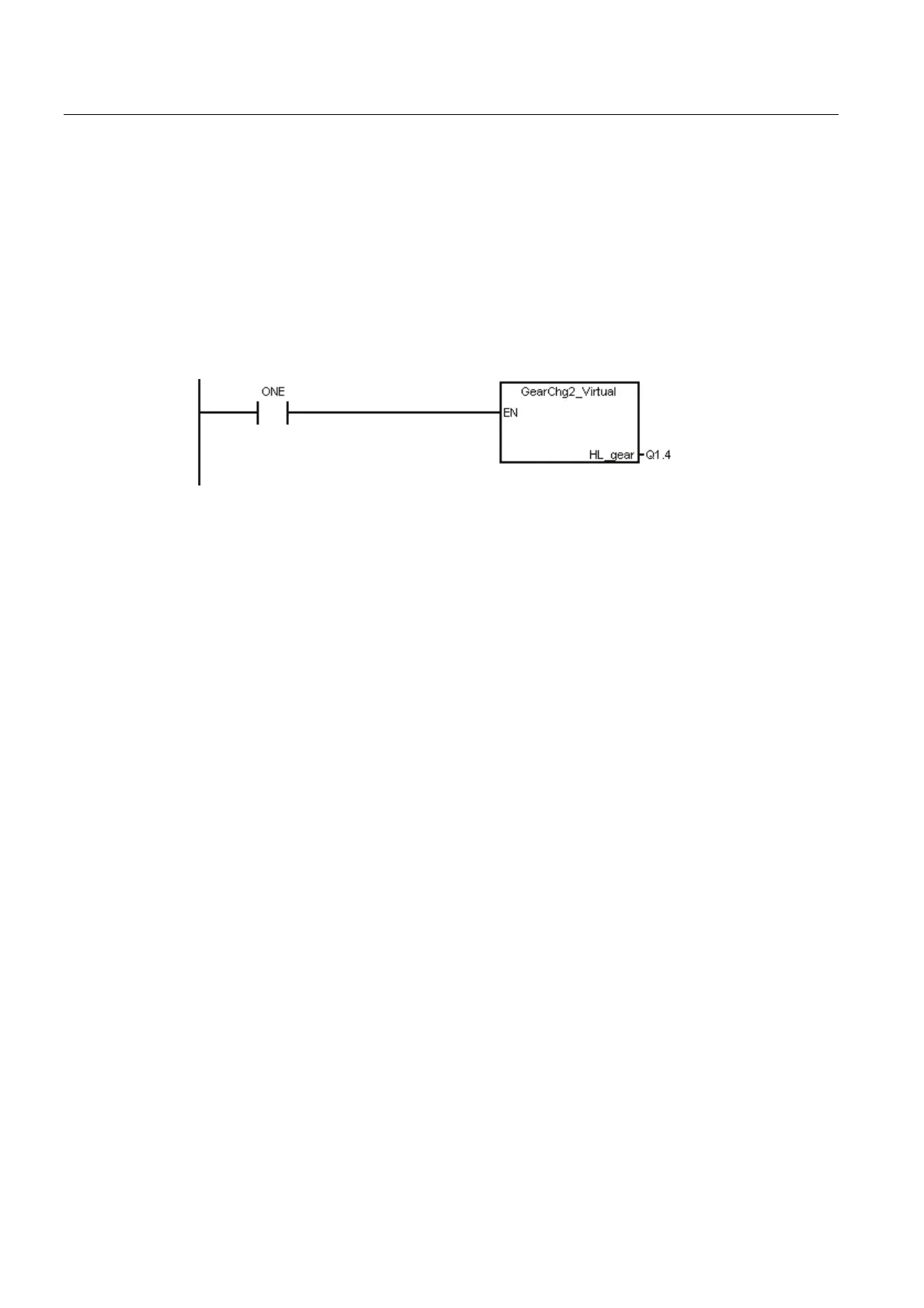

The timing diagram for positioning a tool in the turret using the Hall effect device positioning

sensor is shown as follows:

Loading...

Loading...