PLC Subroutines Manual

Operating Instructions, 12/2012, 6FC5397-2EP10-0BA0

79

PLC sample applications

5

5.1 PLC sample application (turning)

This sample application is applicable to machines with the following configurations:

● Two axes: axes X and Z, with a hardware limit switch respectively in the positive and

negative directions of each axis

● An analog spindle: SP

● HALL effect device turret with six-working stations

● PLC-controlled timely and quantitatively lubrication system

● PLC-controlled cooling system

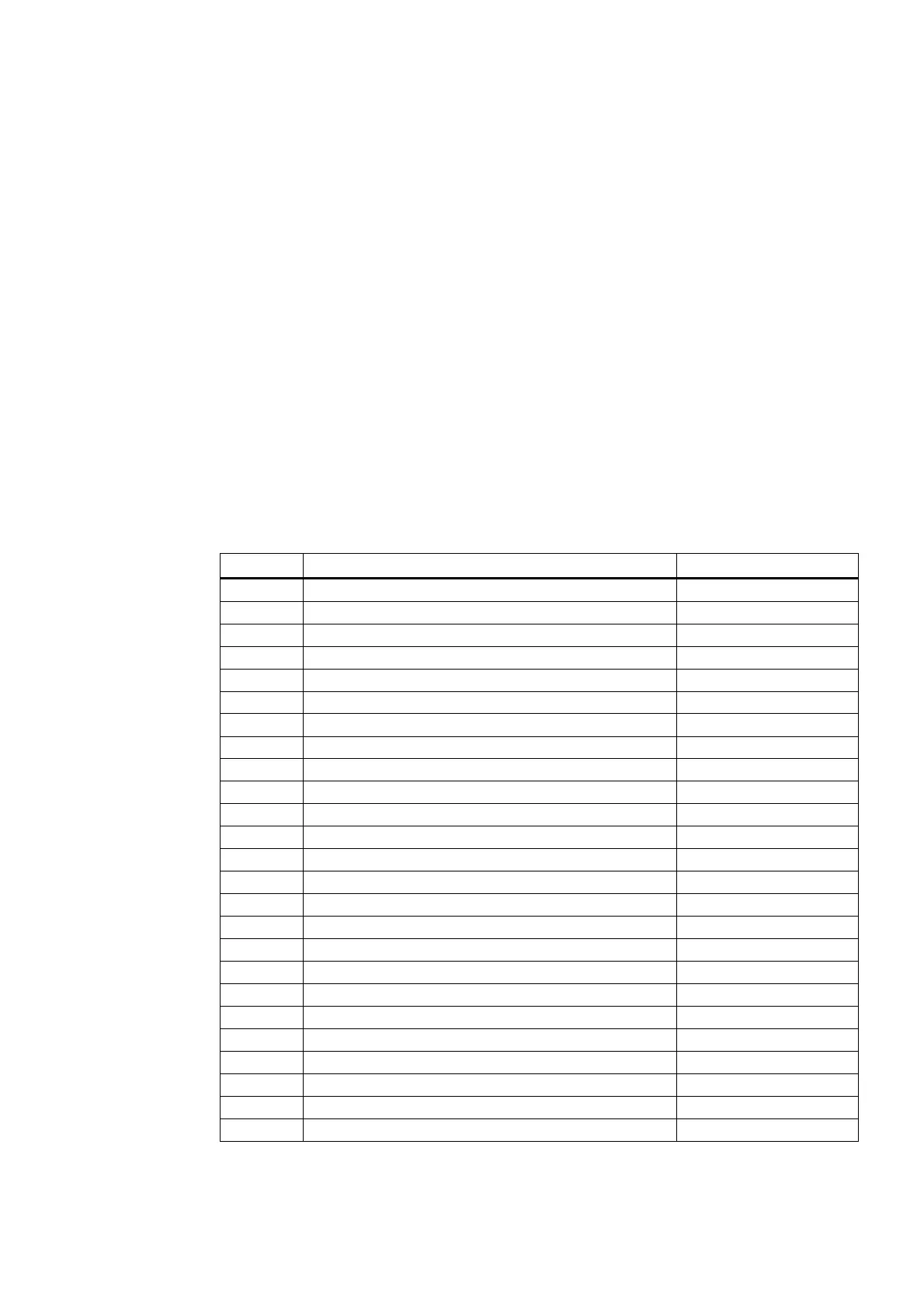

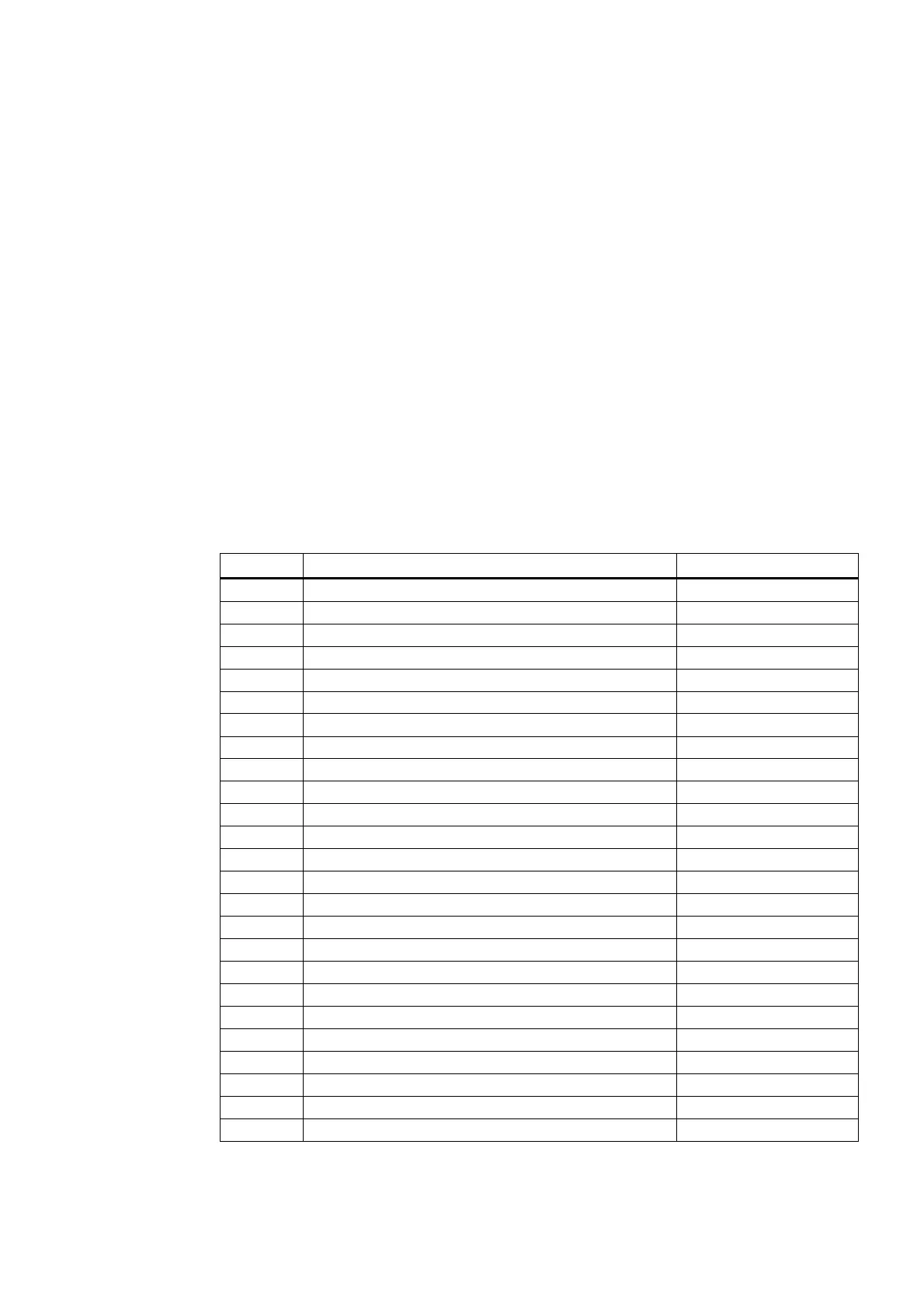

Table 5- 1 Assignment of inputs and outputs

Signal Description Remark

I0.0 Emergency Stop button Normally closed

I0.1 Limit switch in the "+" direction of axis X Normally closed

I0.2 Limit switch in the "-" direction of axis X Normally closed

I0.3

I0.4

I0.5 Limit switch in the "+" direction of axis Z Normally closed

I0.6 Limit switch in the "-" direction of axis Z Normally closed

I0.7 Reference point switch of axis X Normally open

I1.0

I1.1 Reference switch of axis Z Normally open

I1.2 Tool path detecting signal T1 Valid at a low level

I1.3 Tool path detecting signal T2 Valid at a low level

I1.4 Tool path detecting signal T3 Valid at a low level

I1.5 Tool path detecting signal T4 Valid at a low level

I1.6 Tool path detecting signal T5 Valid at a low level

I1.7 Tool path detecting signal T6 Valid at a low level

I2.0 Turret motor overload Normally closed

I2.1 Reserved for other types of turrets Reserved

I2.2

I2.3 Chuck foot switch Normally open

I2.4 Coolant level too low Normally closed

I2.5 Cooling pump motor overload Normally closed

I2.6 Lubricant level to low Normally closed

I2.7 Lubrication pump motor overload Normally closed

I3.0 Reserved

Loading...

Loading...