Do you have a question about the Smartgen APC715 and is the answer not in the manual?

| Brand | Smartgen |

|---|---|

| Model | APC715 |

| Category | Control Unit |

| Language | English |

Alerts to risks of injury or loss of life if procedures are not followed correctly.

Details the function and operation of each pushbutton on the controller panel.

Guide to accessing user menus for parameter settings, language, and other configurations.

Explains the automatic start and stop sequences for the pump unit.

Details the procedures for manual start and stop operations of the pump unit.

Describes how the pump unit engages and disengages load in different operational modes.

Explains methods for adjusting engine speed to control pump unit output pressure.

Lists all warning conditions that alert the operator without stopping the unit.

Details all shutdown alarm types that cause the unit to stop and require manual reset.

Describes shutdown conditions that initiate a cooling delay before engine shutdown.

Explains fault idle conditions that trigger a cooling delay before idle running.

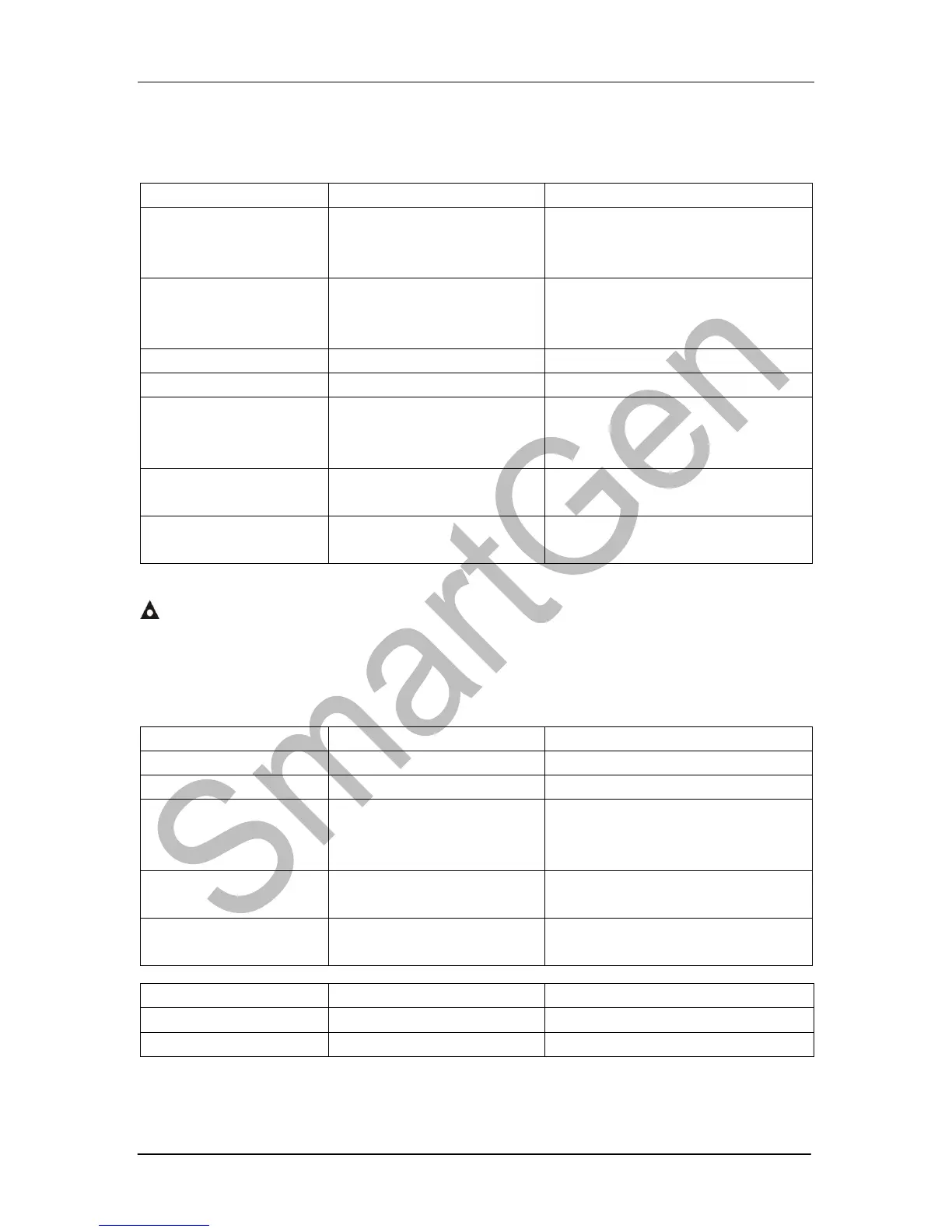

Defines timer and engine settings, their parameters, default values, and descriptions.