HRX-OM-W002-A

Chapter 6 Option

6.2 Option M

【

DI water (Pure water) piping

】

HRR Series

6.2 Option M【DI water (Pure water) piping】

6.2.1 Option M【DI water (Pure water) piping】

This option is for customers who use DI water (pure water) as circulating fluid.

Circulating fluid wetted materials

Stainless (include heat exchanger brazing),

Aluminum oxide ceramic, SiC, Carbon, PP, PE,

POM, FKM, EPDM, PVC (No. copper used)

Available DI water is electric conductivity :2μS/cm or more. (Resistivity:

0.5MΩ・cm or less.)

This M option does not have electric resistance/ electric conductivity

control function.If this function is necessary, option DM 【Electric

conductivity control function, DI water(Pure water piping)】should be

choose.

6.3 Option T【High-pressure pump mounted】

6.3.1 Option T【High-pressure pump mounted】

With option T (high pressure pump mounted), the discharge pressure is

increased.

The high head pump uses a mechanical seal.

Thermo Chiller indicates notice for maintenance when driving time is

passed a recommended preventive maintenance hours. Please contact to

service center to ask for maintenance of the pump and mechanical seal.

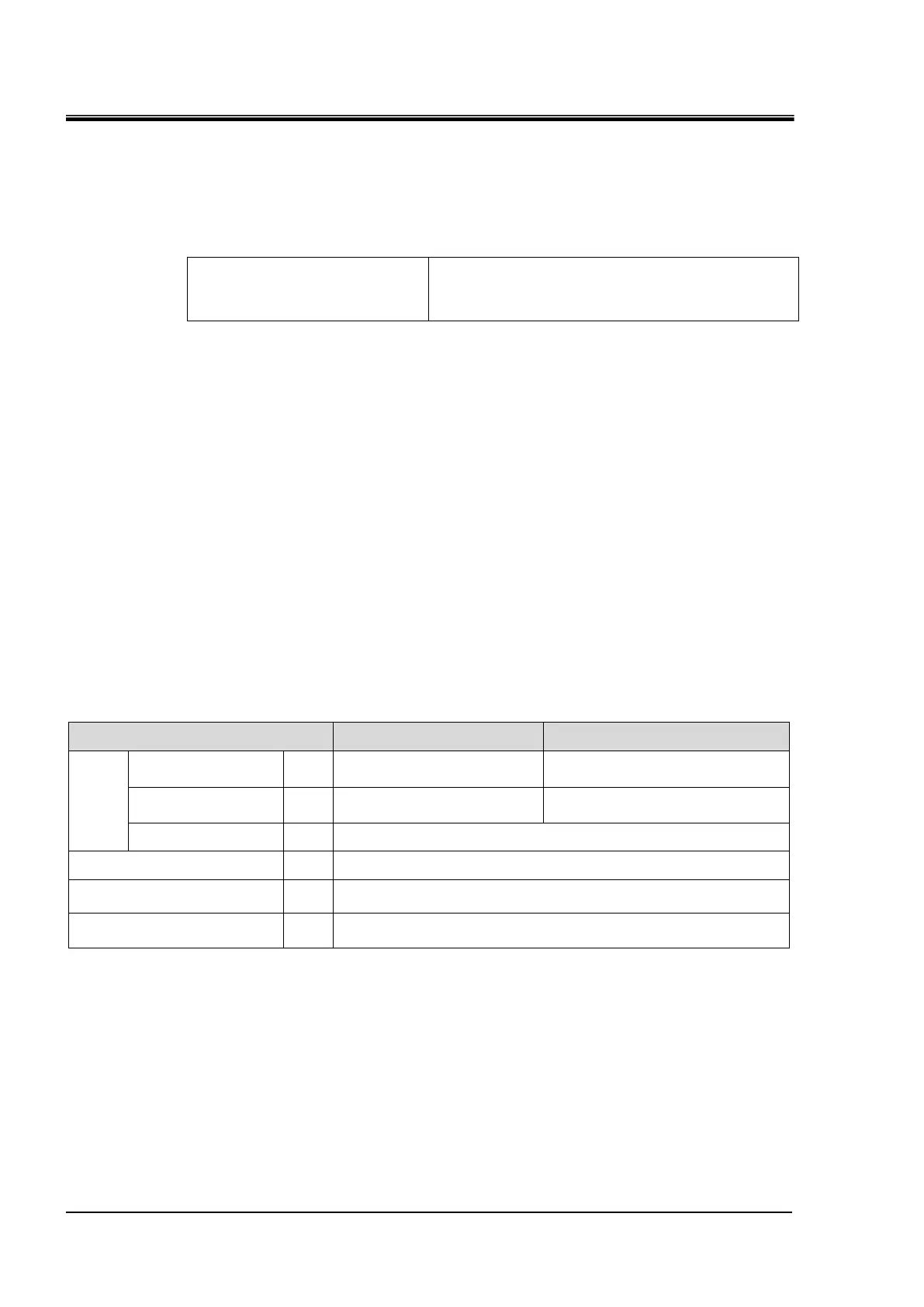

HRR012/018/024/030-□-20-T

HRR012/018/024/030-□-20-MT

Note1)

Rated flow(50/60Hz)

Note2

)

3

)

Maximum pumphead

(50/60Hz)

Recommended earth leakage

breaker capacity

The cooling capacity reduces about 300W from the value in the catalog.

(due to an increase in heat generation of the pump)

Note 1)-MT:Applicable to DI water piping + High pressure pump

Note 2) The capacity at the thermo-chiller outlet when the circulating fluid temperature is 20℃.

Note 3) Required minimum flow rate for cooling capacity or maintaining the temperature stability.

Note 4) Cooling capacity will decrease as pump power increases.

Note 5) When the option,high pressure pump mounted, is selected, the product weight is increased by

5kg.

*No change in external dimensions of this product.

Loading...

Loading...