ENGINE 3-53

CYLINDER

CRANKCASE SERVICING (3-56)

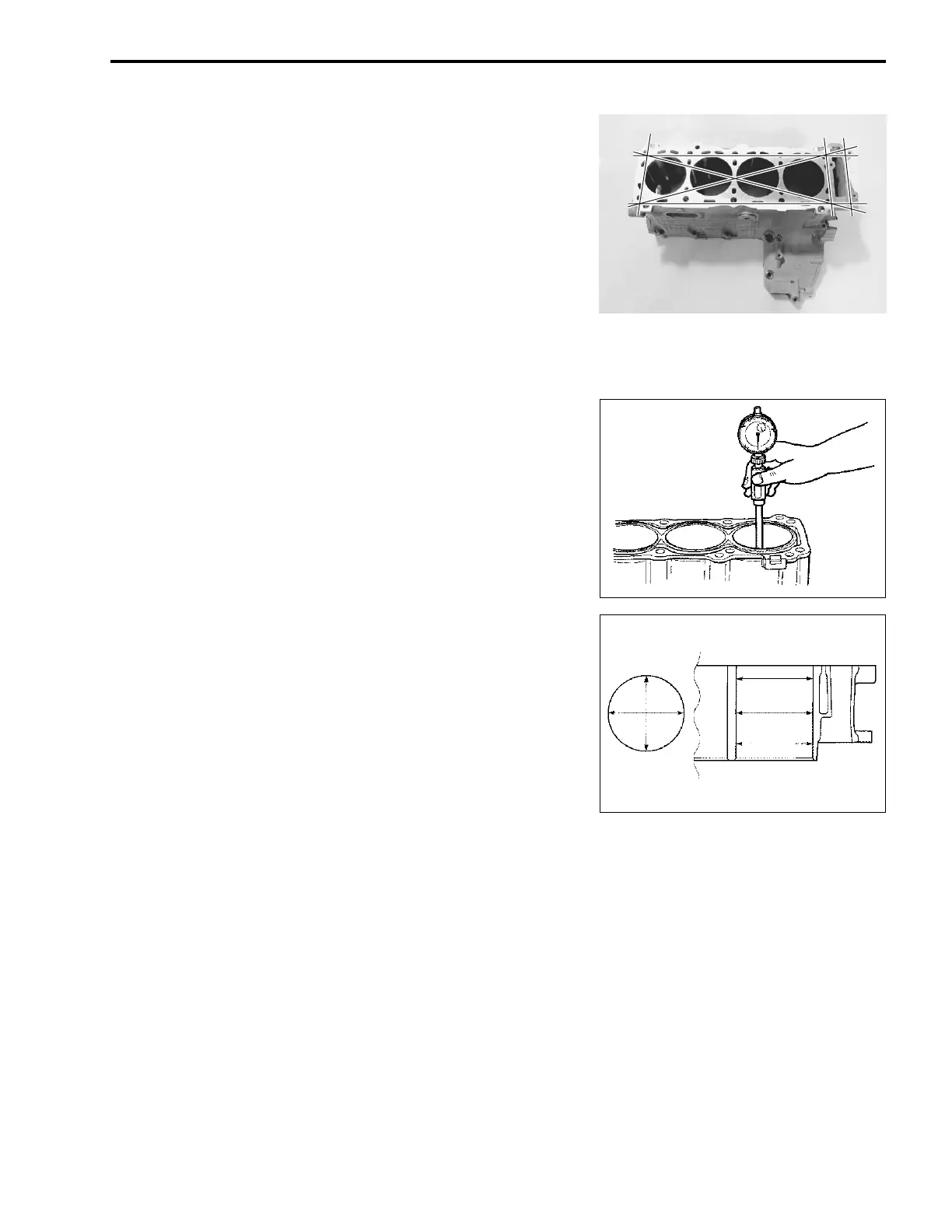

CYLINDER DISTORTION

• Check the gasketed surface of the cylinder for distortion with

a straightedge and thickness gauge, taking a clearance read-

ing at several places as indicated.

• If the largest reading at any position of the straightedge

exceeds the limit, replace the crankcase set.

Cylinder distortion:

Service Limit: 0.02 mm (0.008 in)

09900-20803: Thickness gauge

CYLINDER BORE

• Inspect the cylinder wall for any scratches, nicks or other

damage.

• Measure the cylinder bore diameter at six places.

Cylinder bore:

Standard: 73.400 – 73.415 mm (2.8900 – 2.8903 in)

09900-20508: Cylinder gauge set

SAMPLE

Loading...

Loading...