ENGINE 3-63

BALANCER SHAFT

DISASSEMBLY

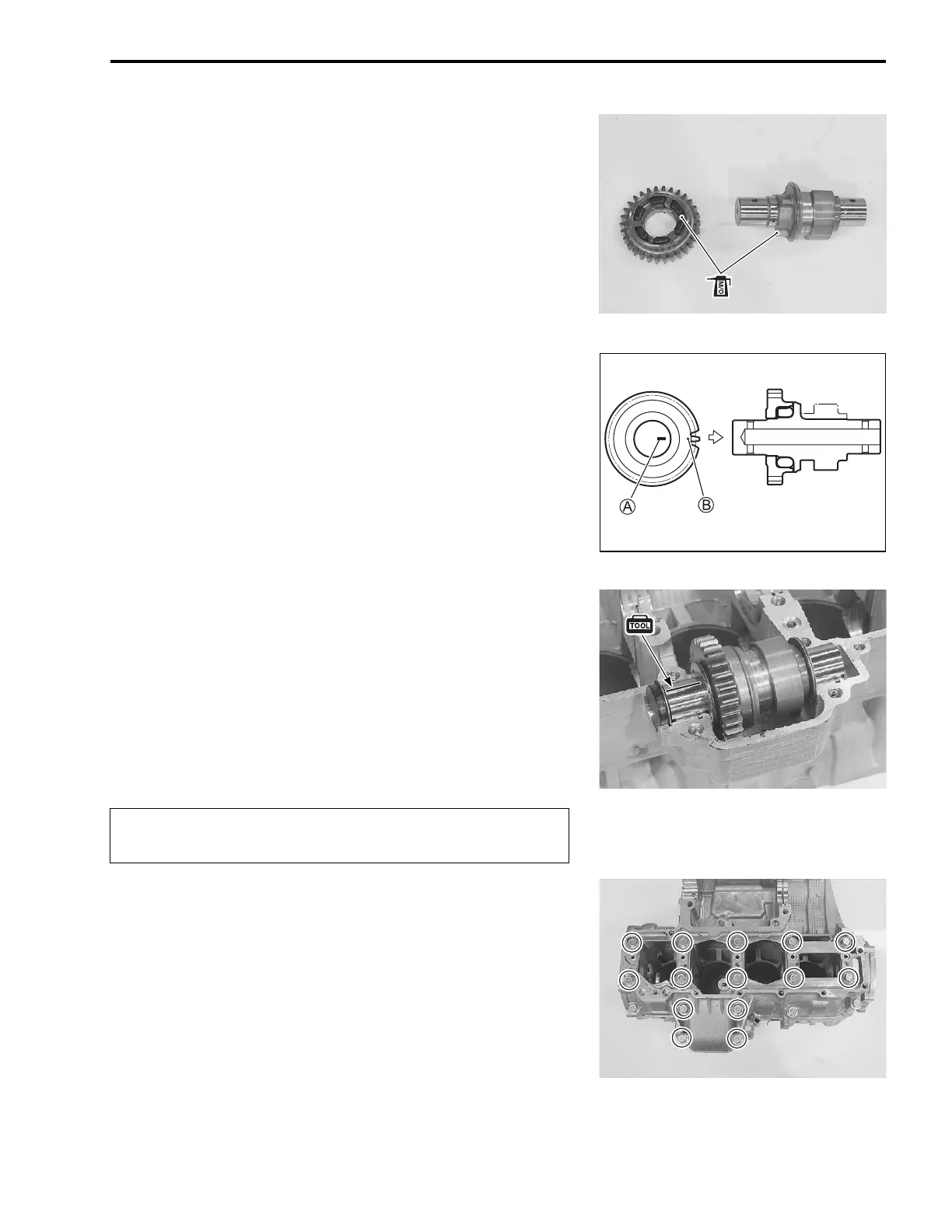

• Remove the balancer gear along with the dampers from the

balancer shaft.

INSPECTION

• Inspect the damper for wear and damage, replace it if any

defects are found.

REASSEMBLY

• Apply MOLYBDENUM OIL SOLUTION to each part.

MOLYBDENUM OIL SOLUTION

• Set the dampers and install the balancer shaft to balancer

gear.

NOTE:

* Fit the stopper of the balancer shaft between the dampers.

* Align the line A on the balancer shaft with the punch B on the

balancer gear.

BALANCER SHAFT JOURNAL BEARING

INSPECTION

• Inspect each bearing of upper and middle crankcases for any

damage.

SELECTION

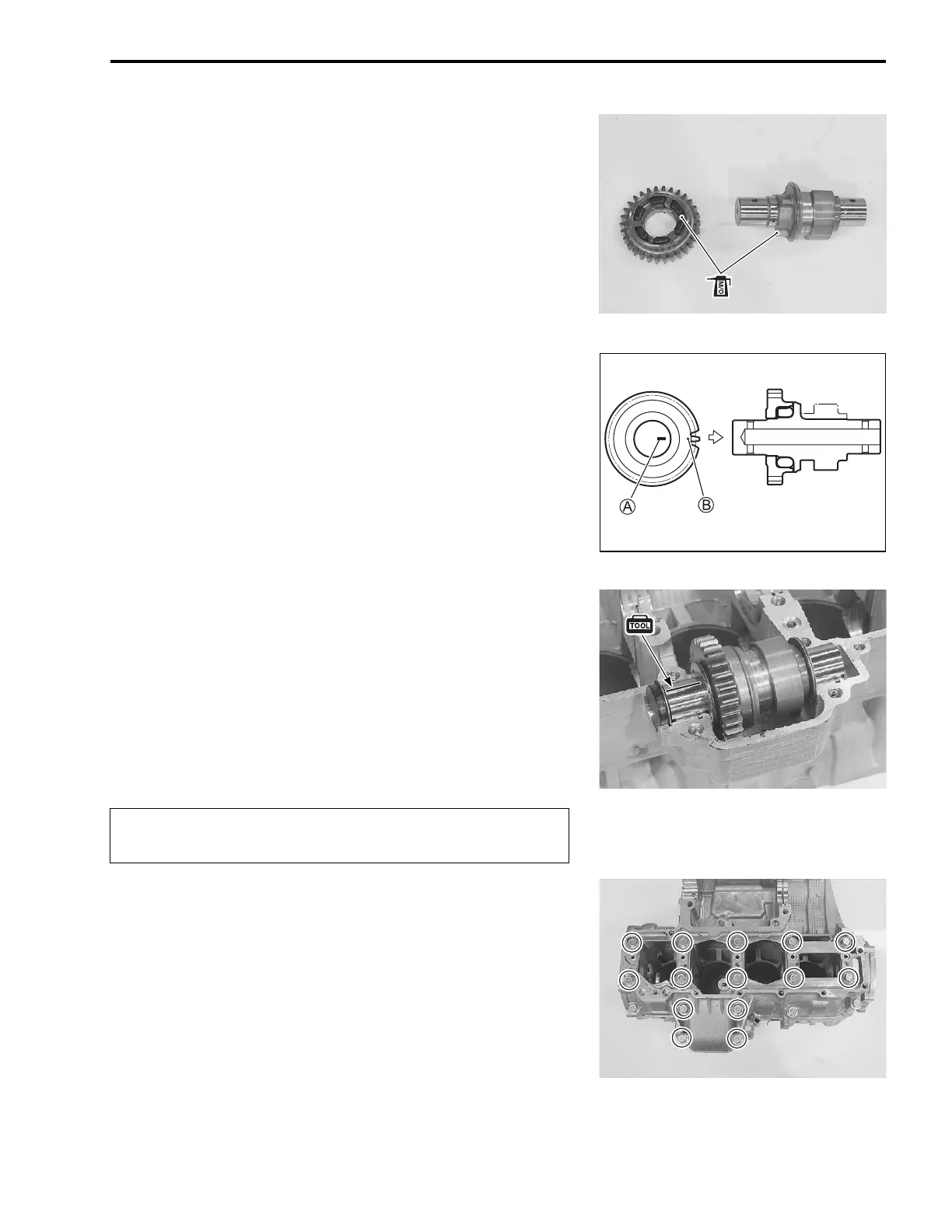

• Place the plastigauge axially along the balancer shaft journal

as shown.

09900-22301: Plastigauge

• Mate the middle crankcase with the upper crankcase, and

tighten the crankcase bolts (M8) and crankshaft bolts(M8) to

the specified torque.

Crankshaft journal bolt (M9):

Initial : 18 N·m (1.8 kgf-m, 13.0 lb-ft)

Final : 50°

Crankcase bolt (M8):

Initial : 15 N·m (1.5 kgf-m, 11.0 lb-ft)

Final : 26 N·m (2.6 kgf-m, 19.0 lb-ft)

Never rotate the balancer shaft when a piece of plasti-

gauge is installed.

SAMPLE

Loading...

Loading...