ENGINE 3-69

CRANKSHAFT JOURNAL BEARING

INSPECTION

• Inspect each bearing of upper and middle crankcases for any

damage.

SELECTION

• Place the plastigauge axially along the crankshaft journal,

avoiding the oil hole, as shown.

09900-22301: Plastigauge

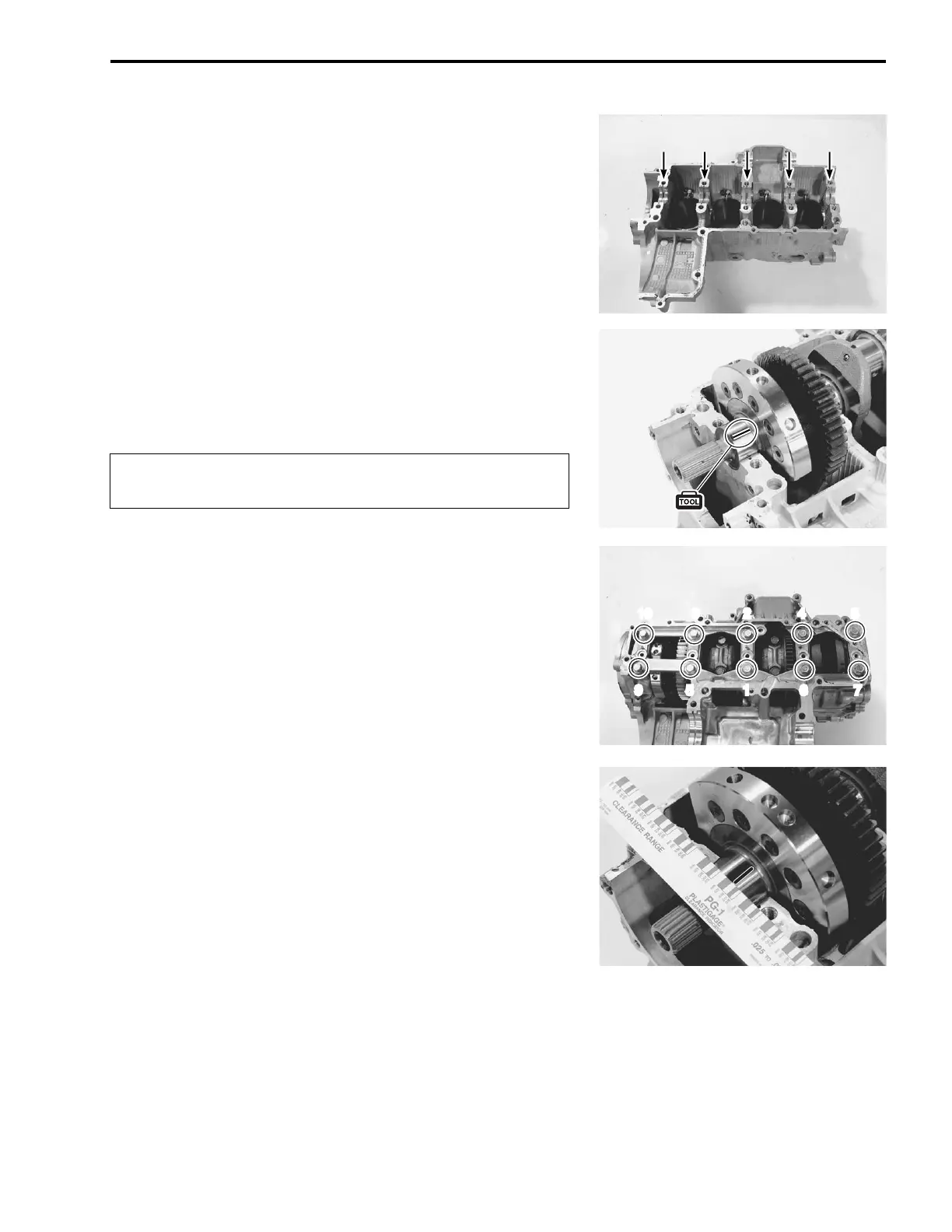

• Tighten the crankshaft journal bolts (M9) in ascending order

of numbers assigned to these bolts. Tighten each bolt a little

at a time to equalize the pressure in the following two steps.

Crankshaft journal bolt: (M9)

Initial : 18 N·m (1.8 kgf-m, 13.0 lb-ft)

Final : 50°

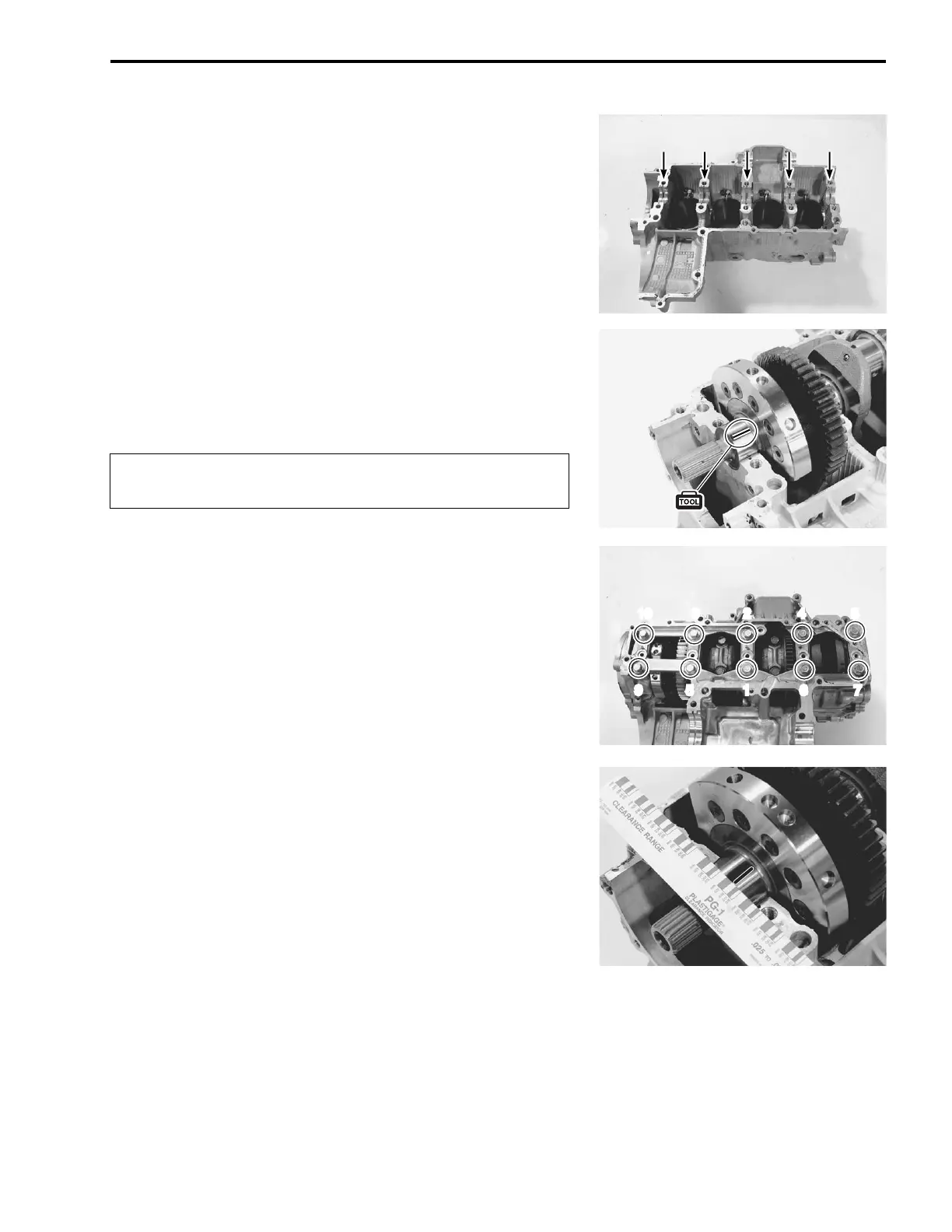

• Remove the middle crankcase and measure the width of the

compressed plastigauge using the envelope scale. This mea-

surement should be taken at the widest part of the com-

pressed plastigauge.

Crankshaft journal oil clearance:

Standard: 0.010 – 0.028 mm (0.0004 – 0.0011 in)

Service Limit: 0.080 mm (0.0031 in)

• If the oil clearance exceeds the service limit, select the speci-

fied bearings from the bearing selection table.

Never rotate the crankshaft when a piece of plasti-

gauge is installed.

1

2

3

4

5

6

7

8

9

10

SAMPLE

Loading...

Loading...