ENGINE 3-75

• Be sure to bring the concave side of 1st ring to the top when

fitting it to the piston.

• 2nd ring has letters “T” marked on the side. Be sure to bring

the marked side ring to the top when fitting it to the piston.

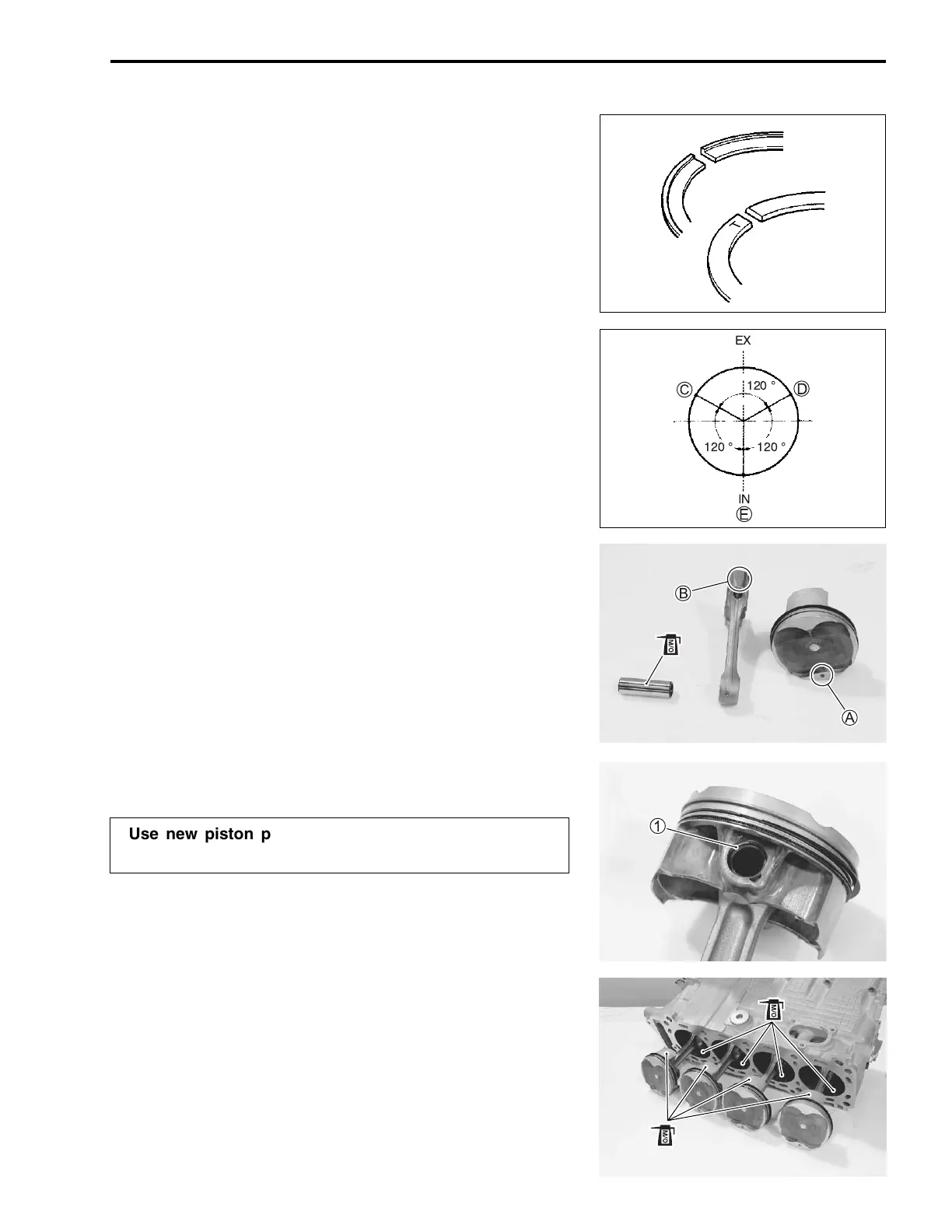

• Position the gaps of the three ring as shown. Before inserting

each piston into the cylinder, check that the gaps are so

located.

C 2nd ring and lower side rail

D Upper side rail

E 1st ring and spacer

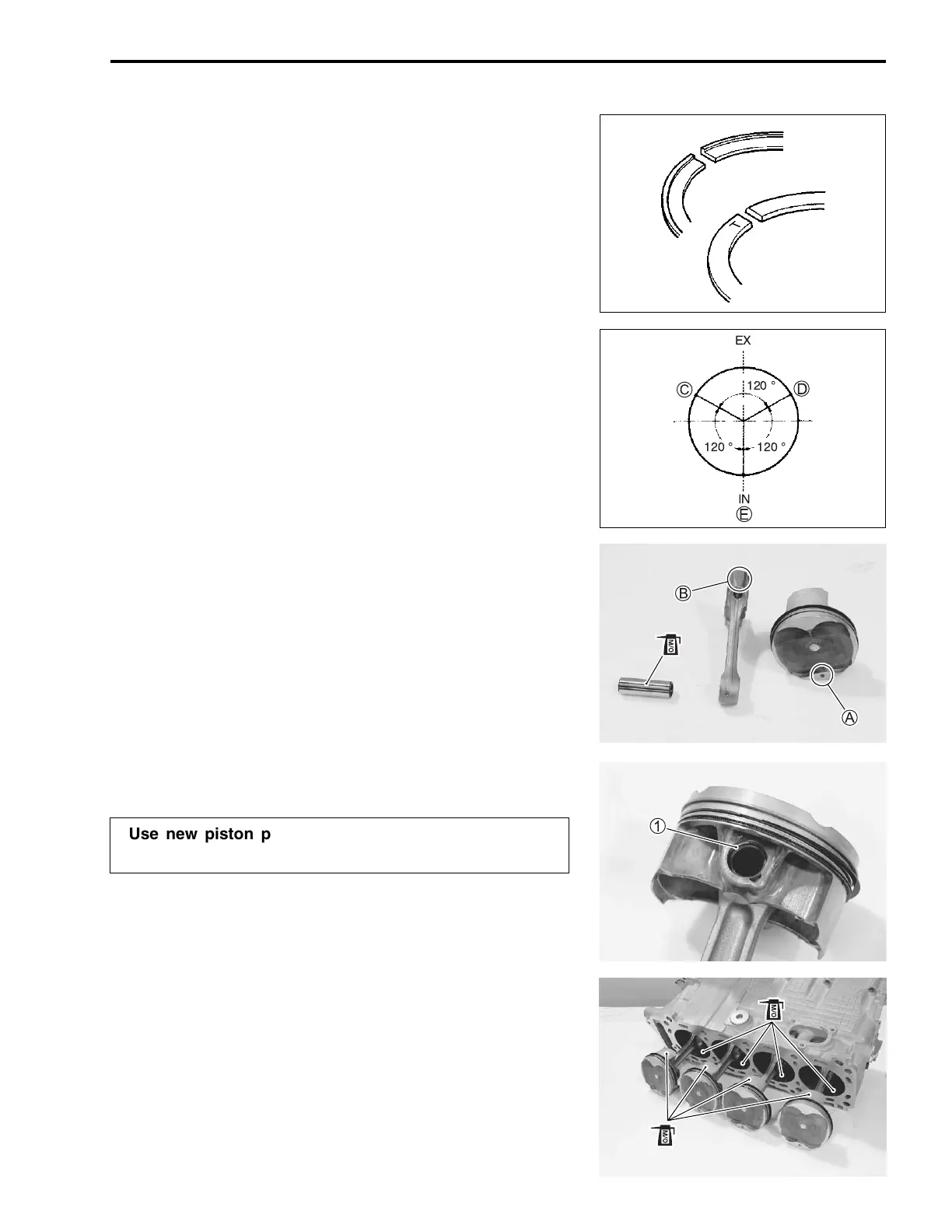

PISTON AND CONROD

• Apply a small quantity of MOLYBDENUM OIL SOLUTION

onto each piston pin.

MOLYBDENUM OIL SOLUTION

• Assemble the piston and conrod.

NOTE:

When installing the pistons, the indent A on the piston head

must be brought to the other side of ID code B on the conrod

big end.

• Install the piston pin circlips 1.

NOTE:

End gap of the circlip should not be aligned with the cutaway in

the piston pin bore.

• Apply a small quantity of MOLYBDENUM OIL SOLUTION to

the sliding surface of the pistons and cylinder walls.

MOLYBDENUM OIL SOLUTION

NOTE:

Be sure to install the pistons in the cylinders from which they

were removed in disassembly, referring to the cylinder numbers,

“1” through “4”, scribed on the piston.

Use new piston pin circlips to prevent circlip failure

which will occur with a bend one.

SAMPLE

Loading...

Loading...