MEASURES, LOGIC STATES AND COUNTERS

93

NG10 - Manual - 04 - 2022

Oscillography - DFR

Upon programmable trigger, the fault records are recorded in COMTRADE format; the sampled mea-

sures (16 sample per cycle) are stored in a circular shift memory buffer.

The fault record are self-triggered; they are stored in sequential order up the allocated memory is

used up after which the oldest memory is overwritten.

An operating procedure example for the digital fault recording is illustrated inside the ThyVisor sec-

tion.

Following parameters are user-programmable:

• Alarm: when the 80% of the buffer space is reached an alarm may be issued. The system being of

linear type, the records are back-to-back recorded to the end of available memory; the alarm out-

put is a warning in order that the user may download data

[1]

to clear memory for new records

• Pre-trigger and post-trigger time setting

• Selected sampled quantities,

• Analog channels (1...12) allocation,

• Digital channels (1...12) allocation (output relay and/or binary inputs),

• Trigger setup; the information storage starts when a state transition on the selected signal occurs.

(protective element start and/or trip, output relay and/or binary input switching).

COMTRADE

Records are recorded in COMTRADE format; (Common Format for Transient Data); This is a standard

for the data exchange for various types of tests or simulation datas, etc, for power system applica-

tions.

The measurements are recorded in ASCII or BINARY format. COMTRADE files always come by

pairs:

• The “.CFG”-file describing the configuration: number of analog and digital channels, sampling rate,

scale factors, etc.

• The “.DAT”-file containing the data

The COMTRADE is part of IEC 60255-24 standard.

The recording can be analyzed by mean of ThyVisor sw or any other standard compliant viewer.

The record quantity is depending on settings of following parameters:

• Pre-trigger and post-trigger times

• Number of allocated channels.

By means of the following formula the record quantity may be evaluated::

where:

• N record quantity

• v

i

sampled measures

• v

RMS

analog measures (RMS)

• n

B

logic variables (2 up to 16 variables)

• t

pre

pre-trigger time interval

• t

post

post-trigger time interval

• f frequency

Note 1 Data are stored into non-volatile memory; they are retained once power is turned off.

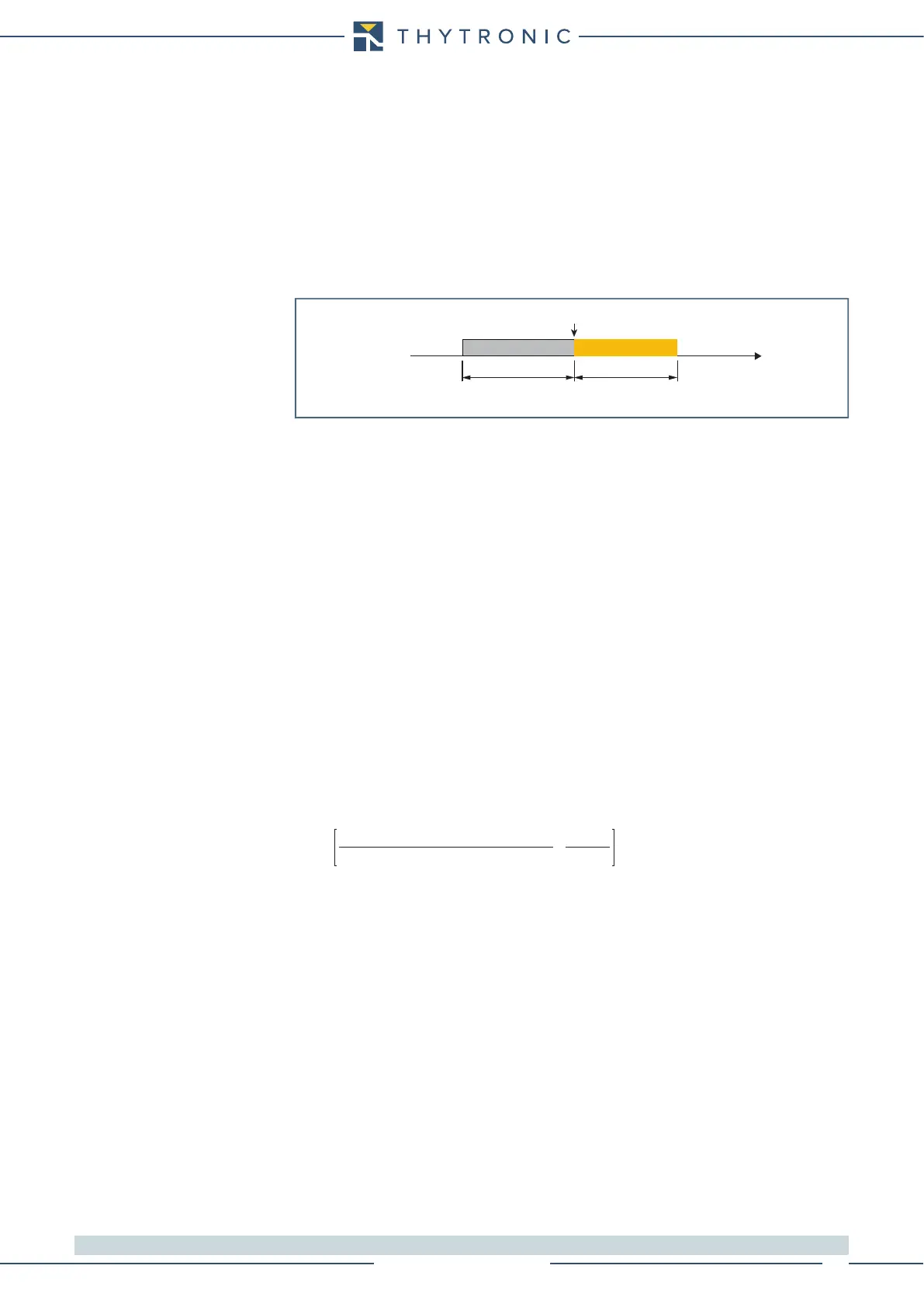

trigger.ai

Oscillographic recorder - trigger

Trigger

Time

pre-trigger post-trigger

= int

(34 + 20 v

i

+ 4 v

RMS

+ n

B

)·

(t

pre

+ t

post

)(s)

·

f (Hz)

Loading...

Loading...