Chapter 6

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Note: Download a free copy of the electrical or hydraulic schematic by visiting www.Toro.com and

searching for your machine from the Manuals link on the home page.

IMPORTANT

Refer to your engine owner’s manual and cutting unit Operator's Manual for

additional maintenance procedures.

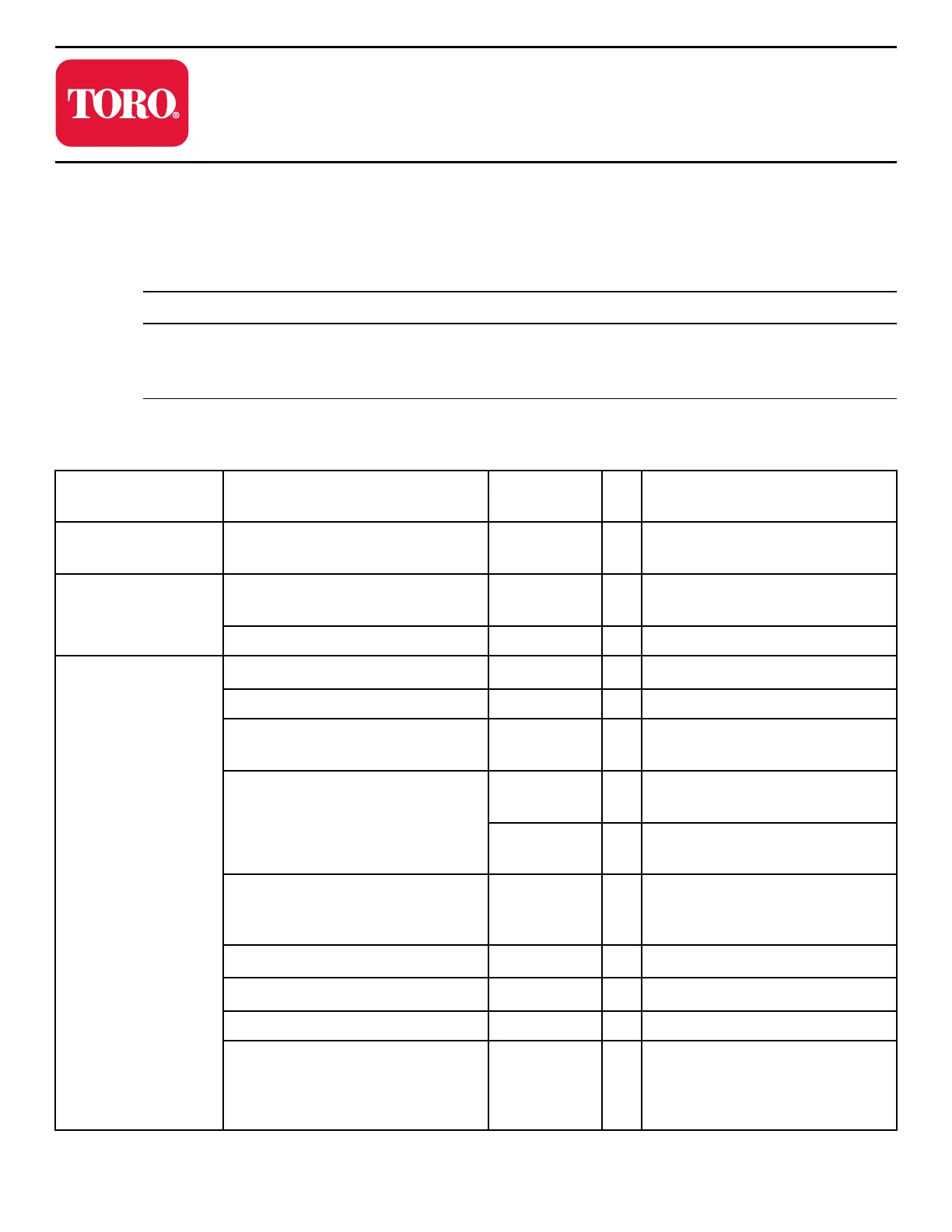

Recommended Maintenance Schedule

Maintenance

Service Interval

Maintenance Procedure Part No.

Qt-

y

Description

After the first hour

Torque the wheel lug nuts to 94

to 122 N∙m (70 to 90 ft-lb).

- - -

After the first 10

hours

Torque the wheel lug nuts to 94

to 122 N∙m (70 to 90 ft-lb).

- - -

Check the alternator-belt tension. 127-2998 1 Alternator belt

Before each use or

daily

Inspect the seat belt(s).

- - -

Check the interlock switches. - - -

Inspect the ROPS components

for wear or damage.

- - -

Check the engine-oil level.

121-6395 1

15W-40 Premium Engine Oil (5

gallons)

121-6394 1

15W-40 Premium Engine Oil

(55 gallons)

Drain water or other

contaminants from the fuel/water

separator.

- - -

Inspect the electrical cables.

- - -

Check the tire air pressure.

- - -

Check the coolant level. - - -

Remove debris from the screen

and radiator/oil cooler (more

frequently in dirty operating

conditions).

- - -

3464-482 A Page 6–1 Maintenance

Loading...

Loading...