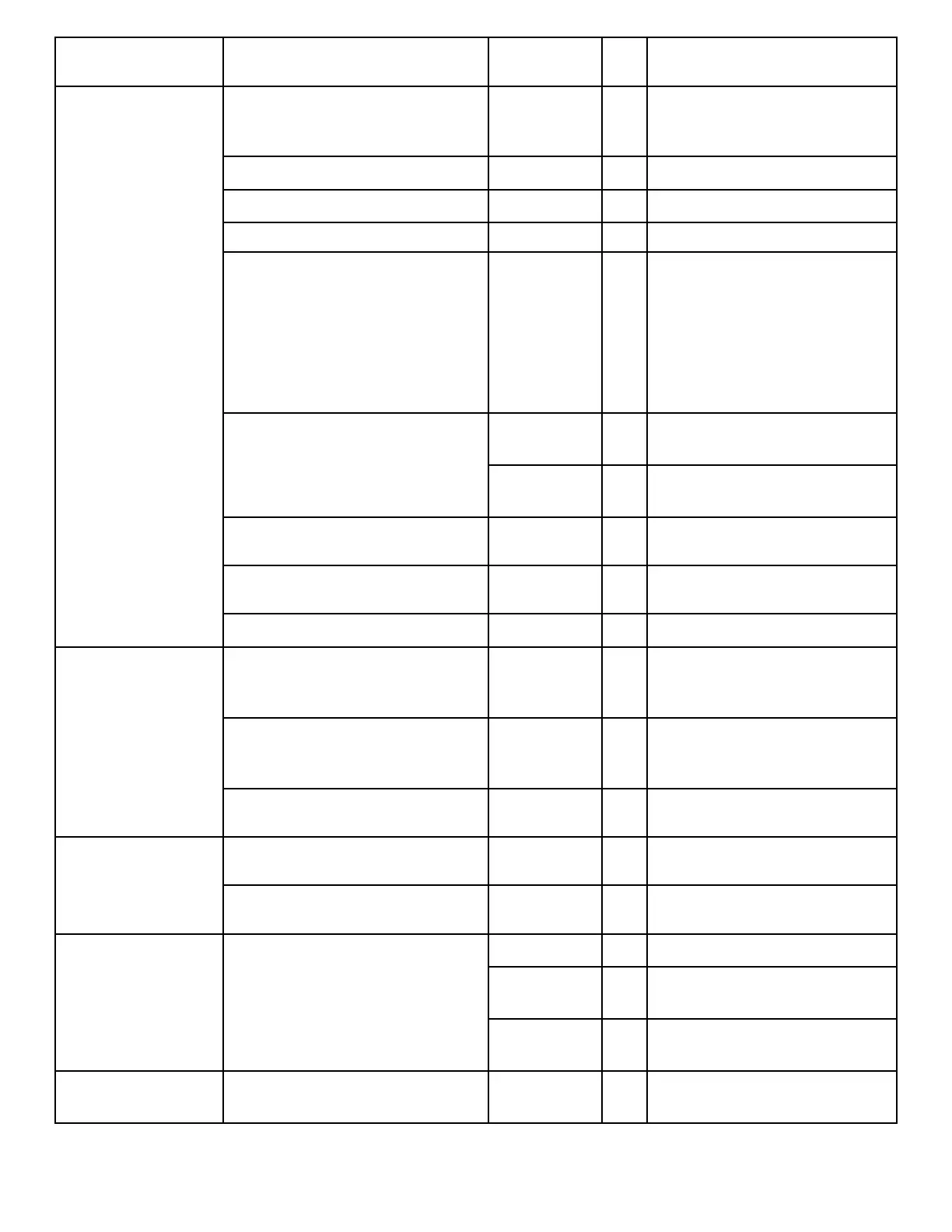

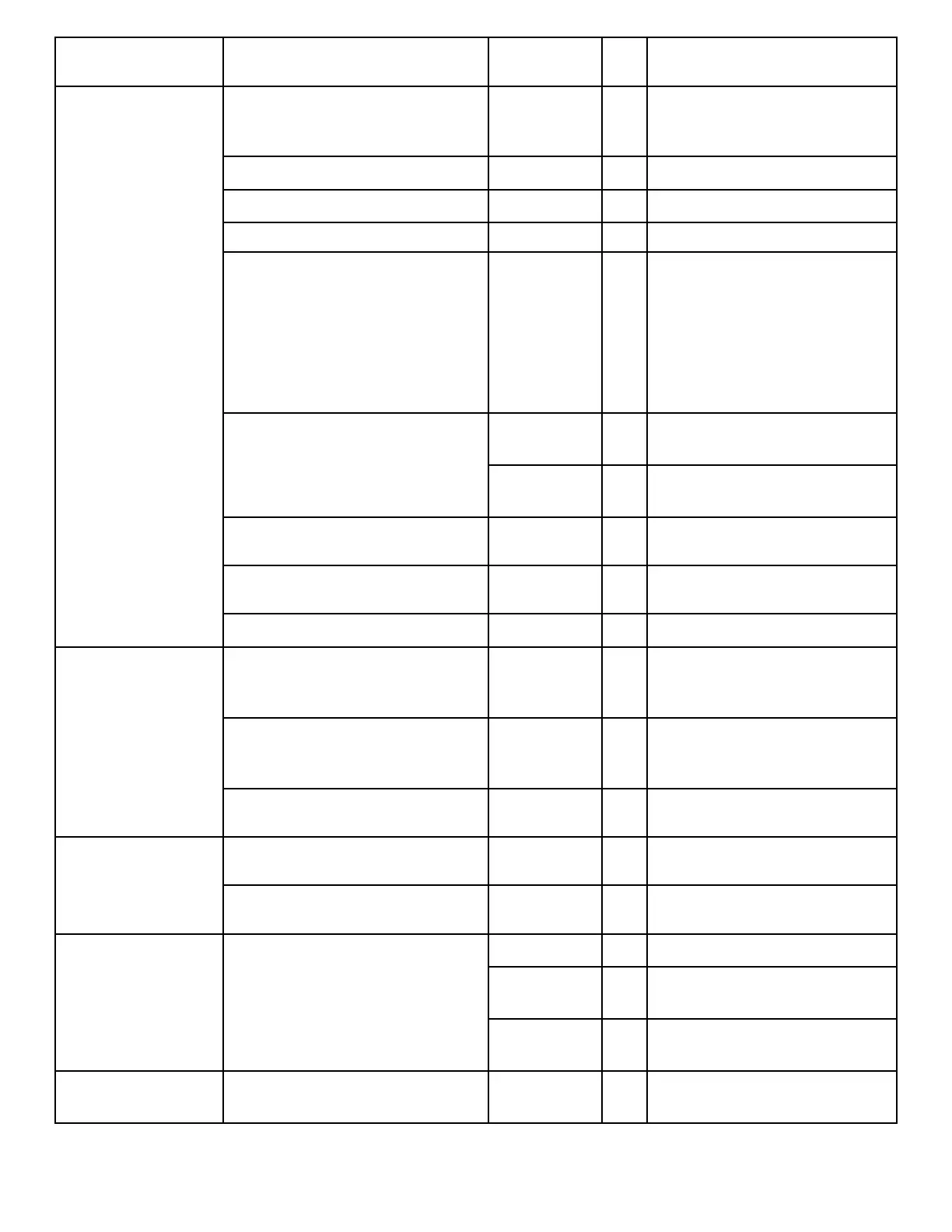

Maintenance

Service Interval

Maintenance Procedure Part No.

Qty Description

Drain water or other

contaminants from the fuel/water

separator.

- - -

Inspect the electrical cables.

- - -

Check the tire air pressure.

- - -

Check the coolant level. - - -

Remove any accumulated

debris, including grass clippings,

leaves, and any other foreign

material from the machine (more

frequently in dirty operating

conditions). Pay particular

attention to the screen, oil

coolers and/or radiator.

- - -

Check the hydraulic-fluid level.

133-8086 1

PX Extended Life Hydraulic

Fluid (5 gallons)

133-8087 1

PX Extended Life Hydraulic

Fluid (55 gallons)

Inspect the hydraulic lines and

hoses.

- - -

Check the reel to bedknife

contact.

- - -

Inspect the seat belt(s).

- - -

Every 50 hours

Grease the bearings and

bushings (and immediately after

every washing).

108-1190 1

Premium all-purpose grease

(14 oz)

Clean the battery and check the

condition of it (or weekly,

whichever comes first).

- - -

Check the battery-cable

connections.

- - -

Every 100 hours

Inspect the cooling system

hoses.

- - -

Check the condition and tension

of the alternator belt.

104-3494 1 Alternator belt

Every 150 hours

Change the engine oil and the

engine-oil filter.

127-0511 1

Engine-oil filter

121-6395 1

15W-40 Premium Engine Oil (5

gallons)

121-6394 1

15W-40 Premium Engine Oil

(55 gallons)

Every 250 hours

Torque the wheel lug nuts to 94

to 122 N∙m (70 to 90 ft-lb).

- - -

3464-478A Page 6–2 Maintenance: Recommended Maintenance Schedule

Loading...

Loading...