Belt Maintenance

Tensioning the Alternator Belt

1. Prepare the machine for maintenance.

2. Open the hood.

G416989

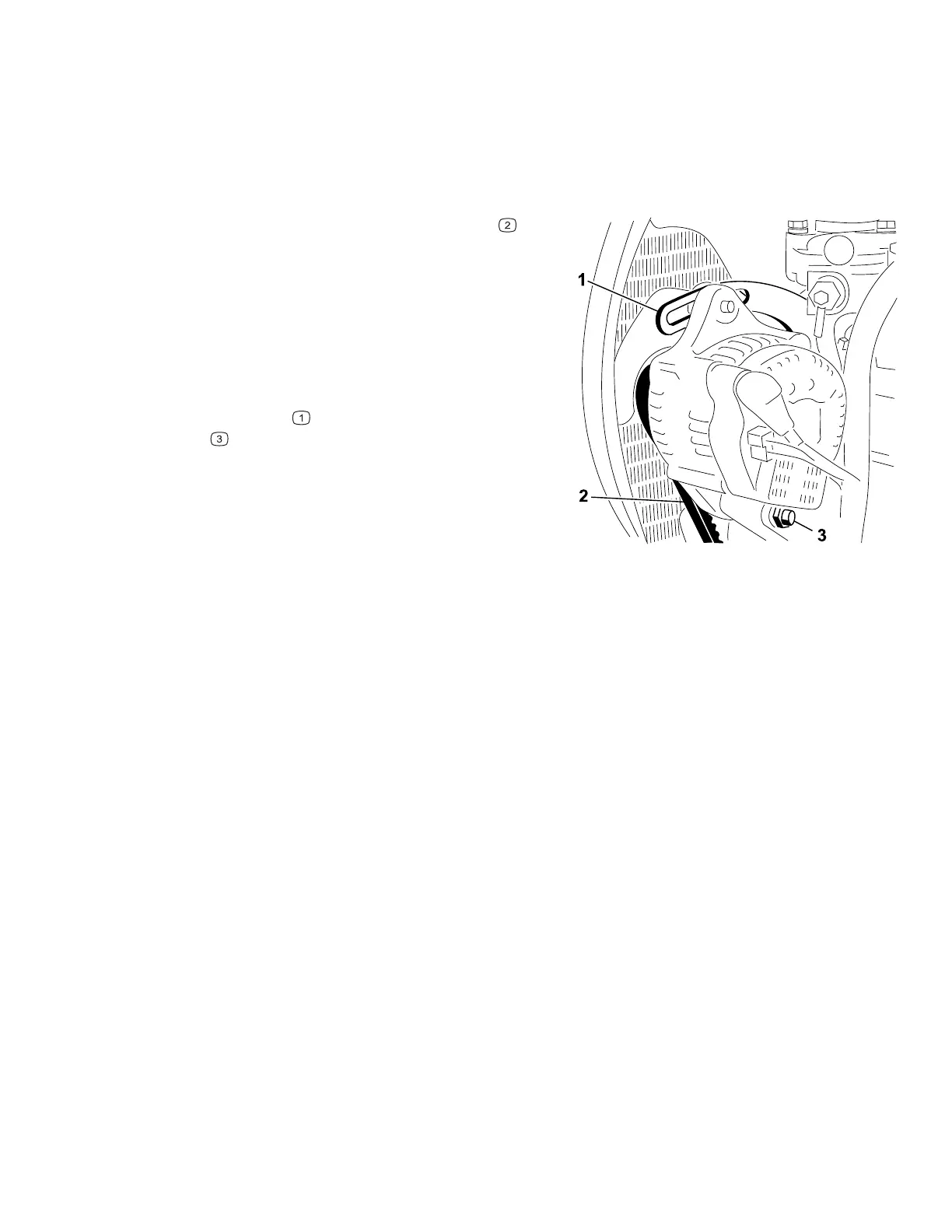

3. Check the tension of the alternator belt by

pressing it midway between the alternator and

the crankshaft pulleys.

Note: With 10 kg (22 lb) of force, the belt

should deflect 11 mm (7/16 inch).

4. If the deflection is incorrect, complete the

following procedure to tension the belt:

A. Loosen the bolts securing the alternator to

the brace

and the alternator pivot bolt

.

B. Insert a pry bar between the alternator and

the engine and move the alternator

outward.

C. When you achieve proper belt tension,

tighten the bolts securing the alternator to

the brace, and the alternator pivot bolt.

5. Close and latch the hood.

Hydraulic System Maintenance

Hydraulic Fluid Specifications

The reservoir is filled at the factory with high-quality hydraulic fluid. Check the level of the

hydraulic fluid before you first start the engine and daily thereafter.

Recommended hydraulic fluid: Toro PX Extended Life Hydraulic Fluid; available in 19 L (5

US gallon) pails or 208 L (55 US gallon) drums.

Note: A machine using the recommended replacement fluid requires less frequent fluid and

filter changes.

Alternative hydraulic fluids: If Toro PX Extended Life Hydraulic Fluid is not available, you

may use another conventional, petroleum-based hydraulic fluid having specifications that

fall within the listed range for all the following material properties and that it meets industry

standards. Do not use synthetic fluid. Consult with your lubricant distributor to identify a

satisfactory product.

Note: Toro does not assume responsibility for damage caused by improper substitutions, so

use products only from reputable manufacturers who will stand behind their

recommendation.

3464-478A Page 6–36 Maintenance: Belt Maintenance

Loading...

Loading...