INSPECTION AND ADJUSTMENT

- Idle Speed and Idle Mixtur

e

IDLE SPEED AND IDLE MIXTUR

E

OBJECTIVE

: To learn

the procedure for inspecting and adjusting the idle speed and idle

mixture

.

PREPARATIONS

:

• SST 09843-18020 Diagnosis check wire

• Tachometer • CO meter

APPLICABLE

ENGINE

: 4A-FE (

Sep

., 1989

)

1

. INITIAL CONDITIONS

(a) Air cleaner installe

d

(b) All pipes and hoses of the air induction system

connecte

d

(c)

All

vacuum lines connecte

d

NOTE

: All vacuum hoses for the EGR system, etc

.,

should be properly connected

.

(d)

All

accessories switched of

f

(e) EFI system wiring connectors securely connected

(f) Ignition timing correctly se

t

(g) Transmission in "N" range

2

. WARM UP ENGIN

E

Allow the engine to reach its normal operating

temperature

.

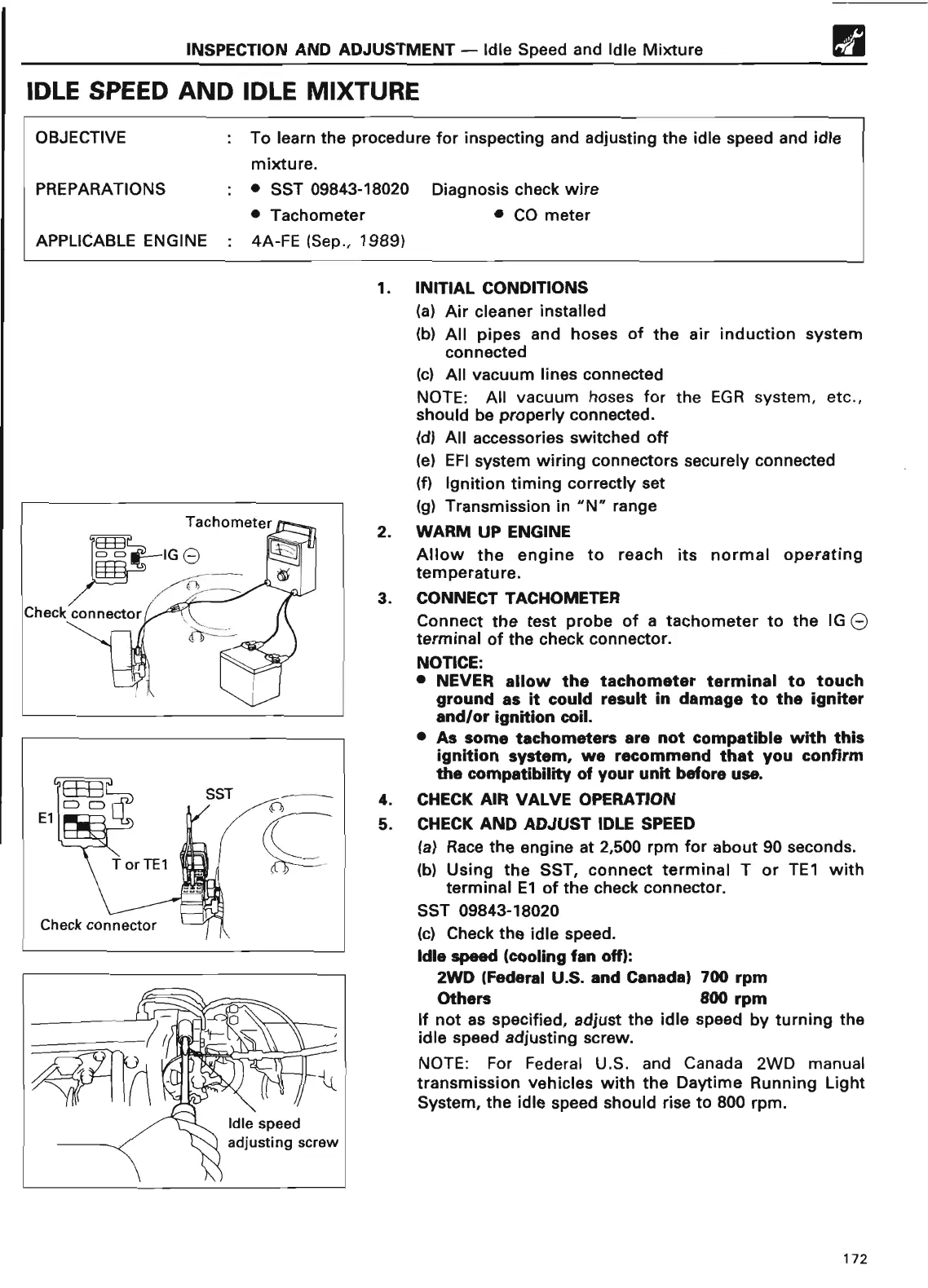

3

. CONNECT TACHOMETE

R

Connect the test probe of a tachometer to the IG ~

terminal of the check connector

.

NOTICE

:

• NEVER allow the tachometer terminal to touch

ground as it could result in damage to the igniter

and/or ignition coil

.

• As some tachometers are not compatible with this

ignition system, we recommend that you confirm

the compatibility of your unit before use

.

4

. CHECK AIR VALVE OPERATION

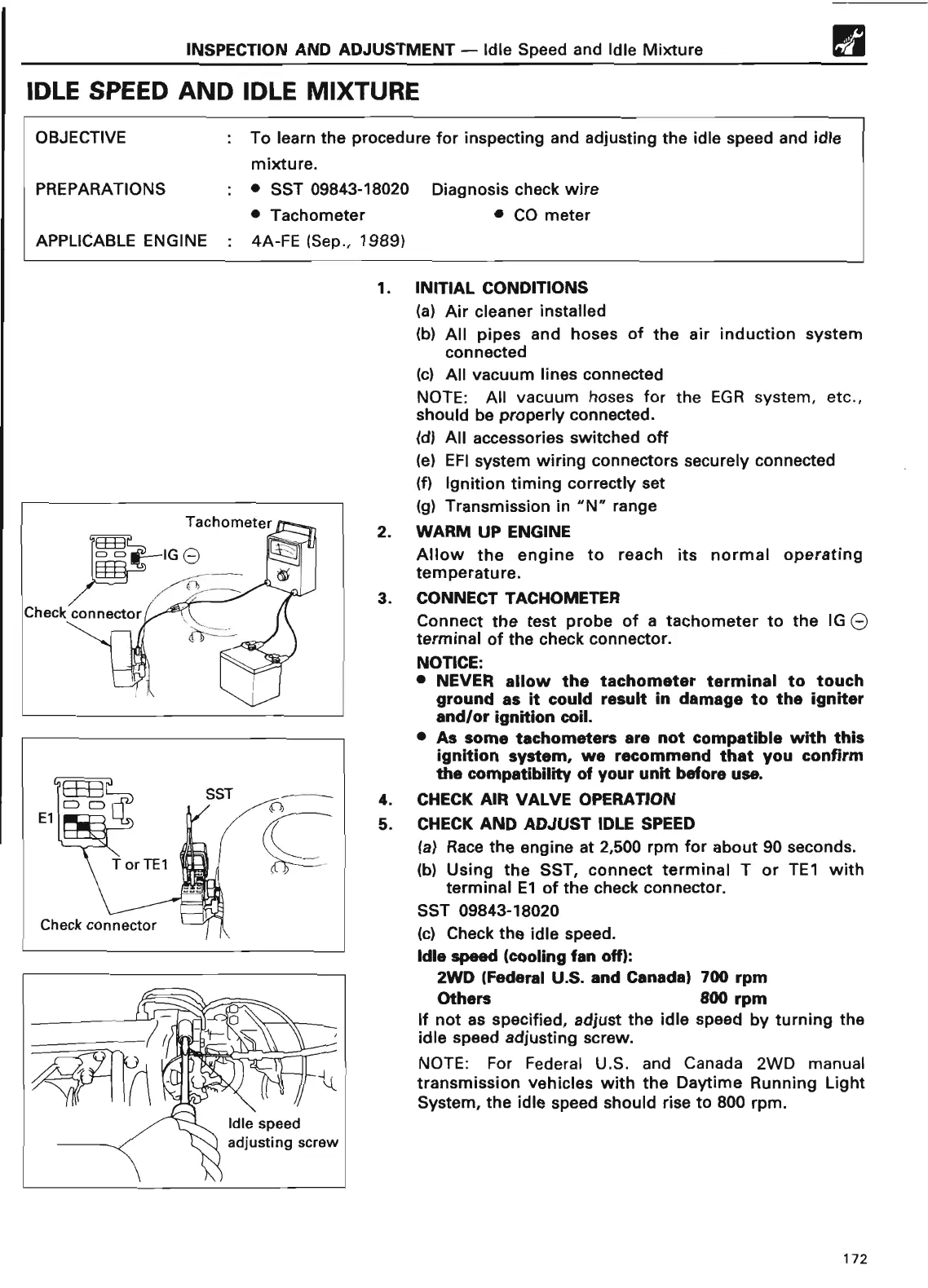

5

. CHECK AND

ADJUST

IDLE SPEE

D

(a) Race the engine at 2,500 rpm for about 90 seconds

.

(b) Using the SST, connect terminal T or TE1 with

terminal El of the check connector

.

SST 09843-1802

0

(c) Check the idle speed

.

Idle speed

(

cooling fan

off)

:

2WD (Federal U

.S

. and Canada) 700 rpm

Others 800 rp

m

If not as specified, adjust the idle speed by turning the

idle speed adjusting screw

.

NOTE

: For Federal U

.S

. and Canada 2WD manual

transmission vehicles with the Daytime Running Light

System, the idle speed should rise to 800 rpm

.

172

Loading...

Loading...