INSPECTION AND ADJUSTMENT

- Manifold Pressure Sensor (Vacuum Sensor

)

MANIFOLD PRESSURE SENSOR

(VACUUM

SENSOR

)

OBJECTIVE

To learn the procedure for inspecting the manifold pressure sensor (vacuum

sensor)

.

PREPARATIONS

.• Voltmeter

(

also called "circuit tester" or "multi-tester")

• Mityvac

(

hand-held vacuum pump

)

APPLICABLE ENGINE

: 4A-FE*

(Sep

., 1989

)

*Except Carina

11 (AT

171) with lean

mixture senso

r

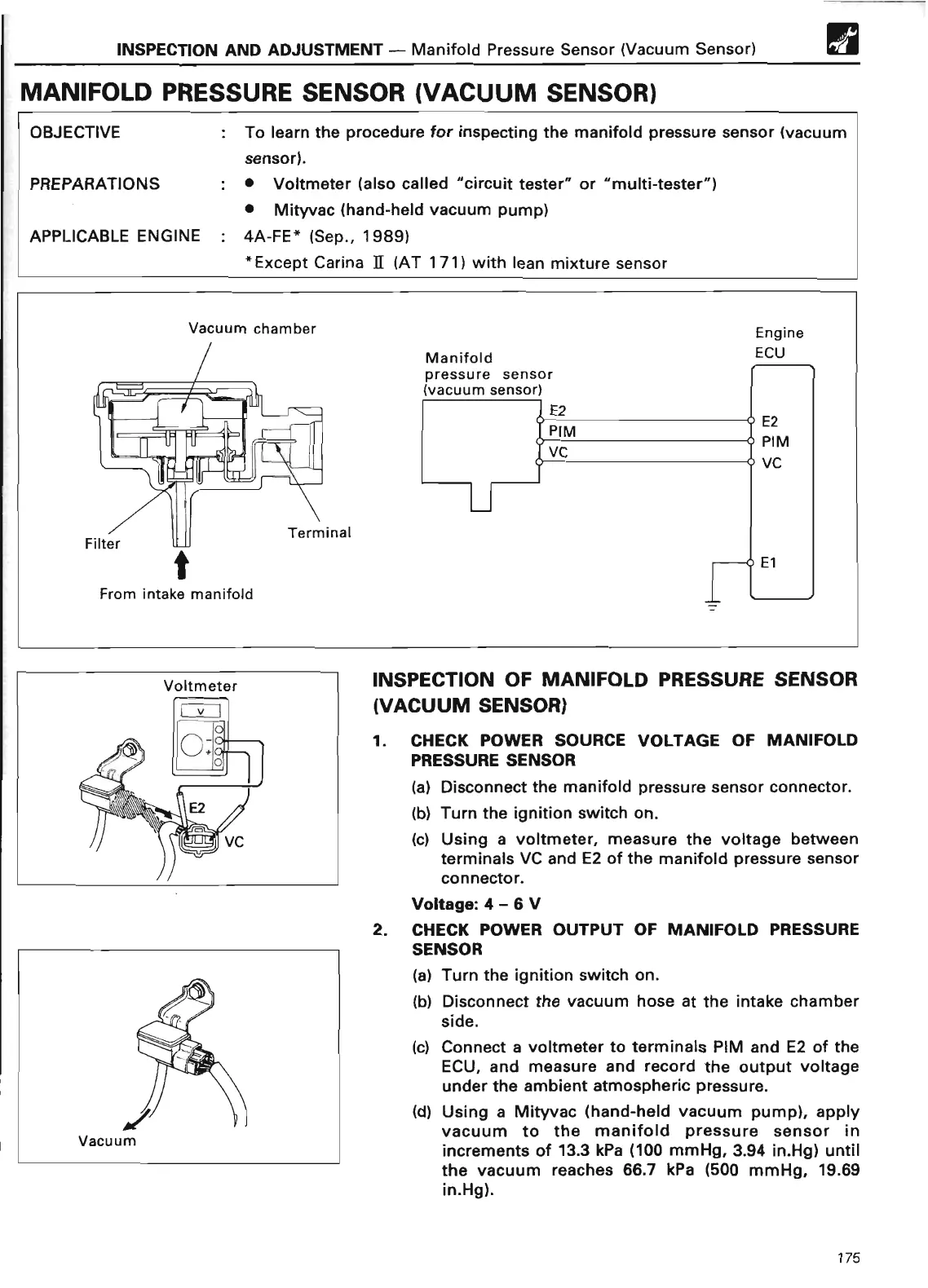

Vacuum chamber

E2

PIM

V

C

~

From intake manifold

INSPECTION OF MANIFOLD

PRESSURE SENSOR

(VACUUM

SENSOR

)

1

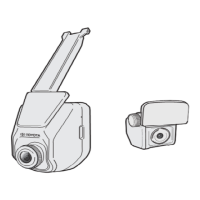

. CHECK POWER

SOURCE VOLTAGE

OF MANIFOLD

PRESSURE SENSO

R

(a) Disconnect the manifold pressure sensor connector

.

(b)

Turn the ignition switch on

.

(c) Using a voltmeter, measure the voltage between

terminals VC and E2 of the manifold pressure sensor

connector

.

Voltage

: 4 - 6

V

2

. CHECK POWER

OUTPUT OF

MANIFOLD PRESSURE

SENSO

R

(a) Turn the ignition switch on

.

(b) Disconnect the vacuum hose at the intake chamber

side

.

(c) Connect a voltmeter to terminals PIM and E2 of the

ECU, and measure and record the output voltage

under the ambient atmospheric pressure

.

(d) Using a Mityvac (hand-held vacuum pump), apply

vacuum to the manifold pressure sensor in

increments of 13

.3 kPa (100 mmHg, 3.94 in

.Hg) until

the vacuum reaches 66

.7 kPa (500 mmHg, 19

.69

in

.Hg)

.

175

Loading...

Loading...