a

ELECTRONIC CONTROL SYSTEM - G and NE Signal Generator

s

3

. SEPARATE TYP

E

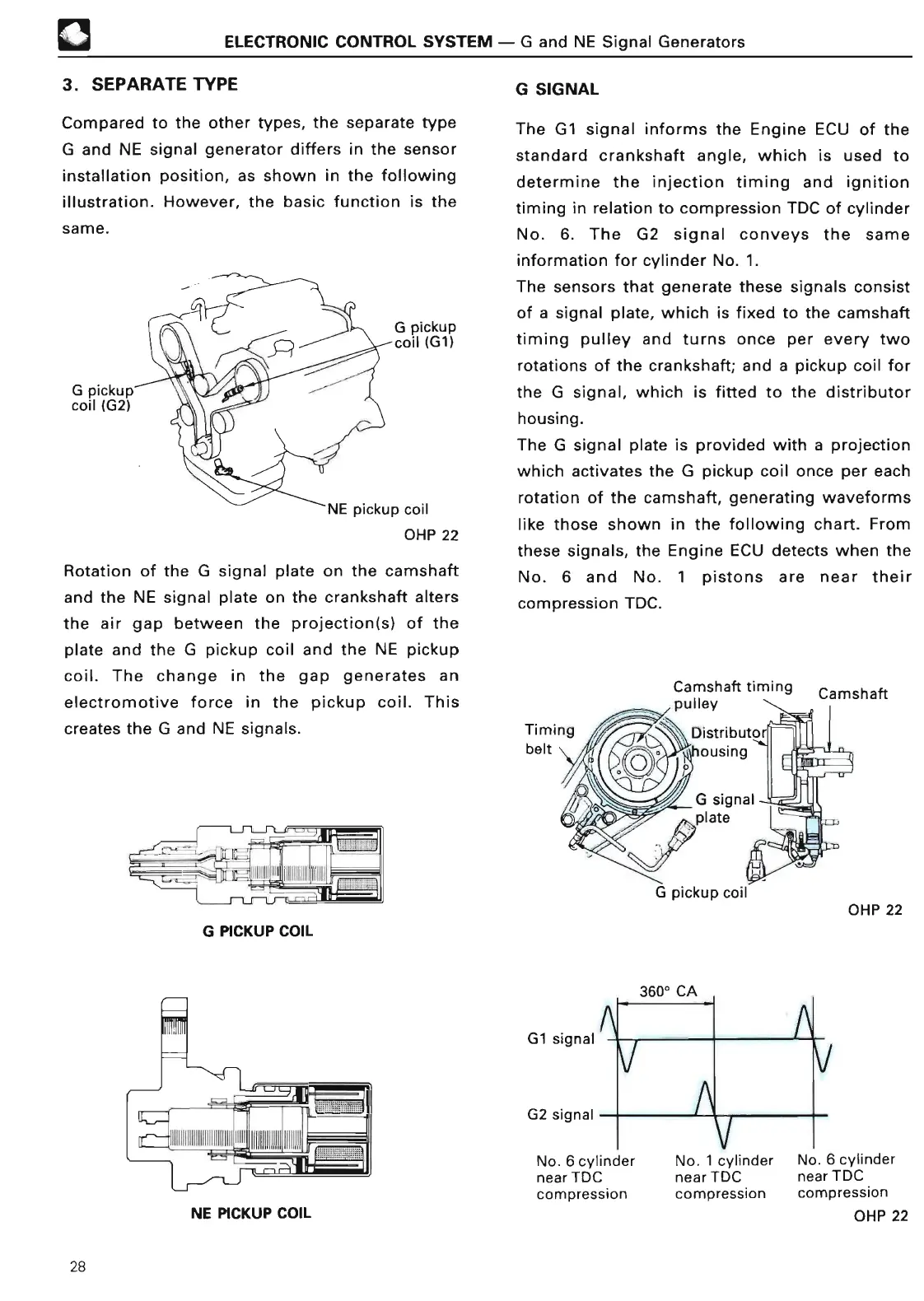

Compared to the other types, the separate type

G and NE signal generator differs in the sensor

installation position, as shown in the following

illustration

. However, the basic function is the

same

.

G pickup

coil (G2)

G pickup

coil (G1

)

NE pickup coil

OHP 2

2

Rotation of the G signal plate on the camshaft

and the NE signal plate on the crankshaft alters

the air gap between the projection(s) of the

plate and the G pickup coil and the NE pickup

coil

. The change in the gap generates an

electromotive force in the pickup coil

. This

creates the G and NE signals

.

L I IIIIIII Illr

.,d,l,„J

L~ _

I

G PICKUP COI

L

NE PICKUP COIL

G SIGNA

L

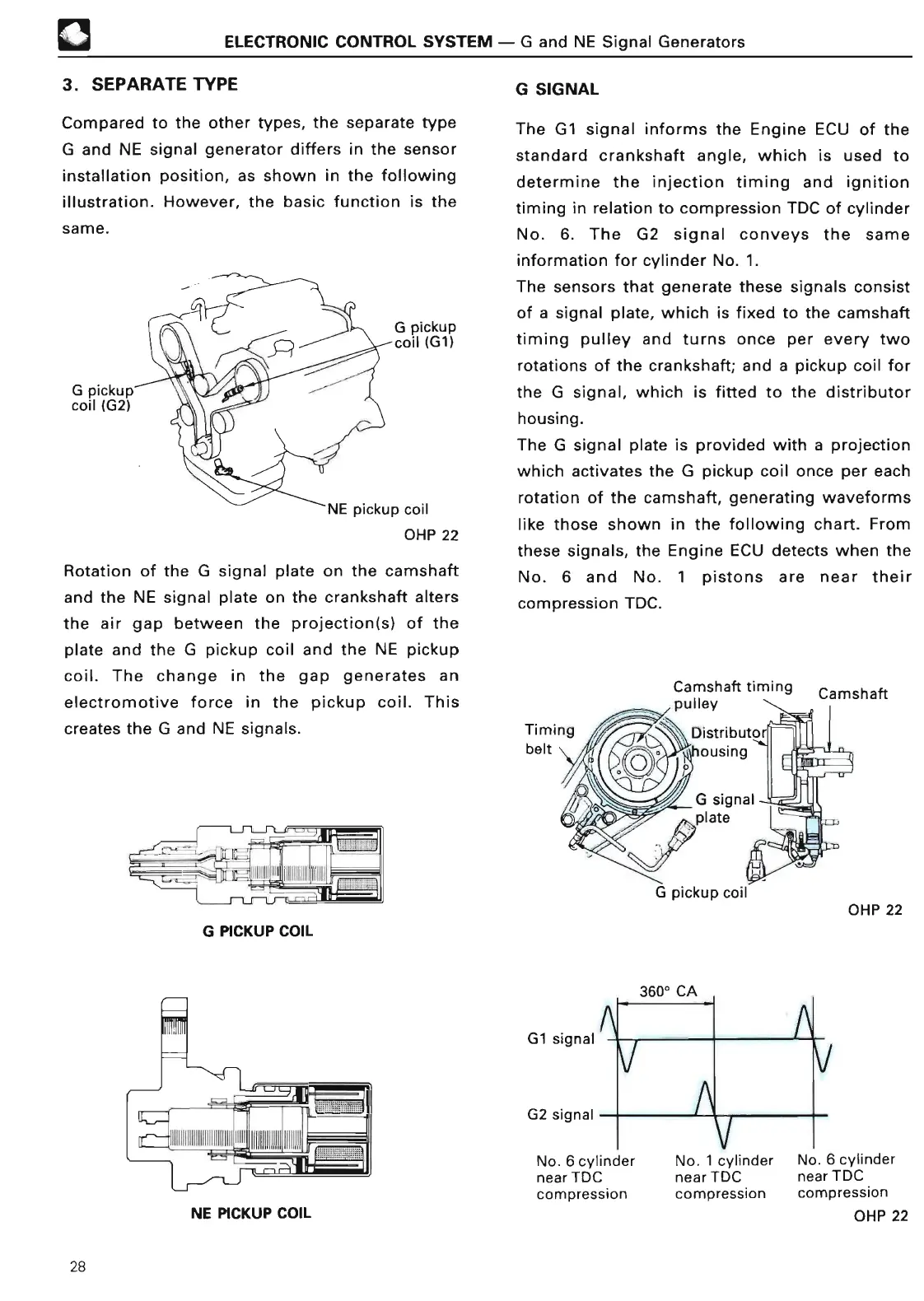

The G1 signal informs the Engine ECU of the

standard crankshaft angle, which is used to

determine the injection timing and ignition

timing in relation to compression TDC of cylinder

No

. 6

. The G2 signal conveys the same

information for cylinder No

. 1

.

The sensors that generate these signals consist

of a signal plate, which is fixed to the camshaft

timing pulley and turns once per every two

rotations of the crankshaft

; and a pickup coil for

the G signal, which is fitted to the distributor

housing

.

The G signal plate is provided with a projection

which activates the G pickup coil once per each

rotation of the camshaft, generating waveforms

like those shown in the following chart

. From

these signals, the Engine ECU detects when the

No

. 6 and No

. 1 pistons are near their

compression TDC

.

Camshaft timin

g

pulle

y

G1 signa

l

G2 signal

A

G pickup coi

l

3600

CA

N

No

. 1 cylinder

near TDC

compression

Camshaf

t

OHP 2

2

No

. 6 cylinder

near TDC

compressio

n

OHP 2

2

No

. 6 cylinder

near TDC

compressio

n

28

Loading...

Loading...