122

Service and Maintenance

Draining compressed air system

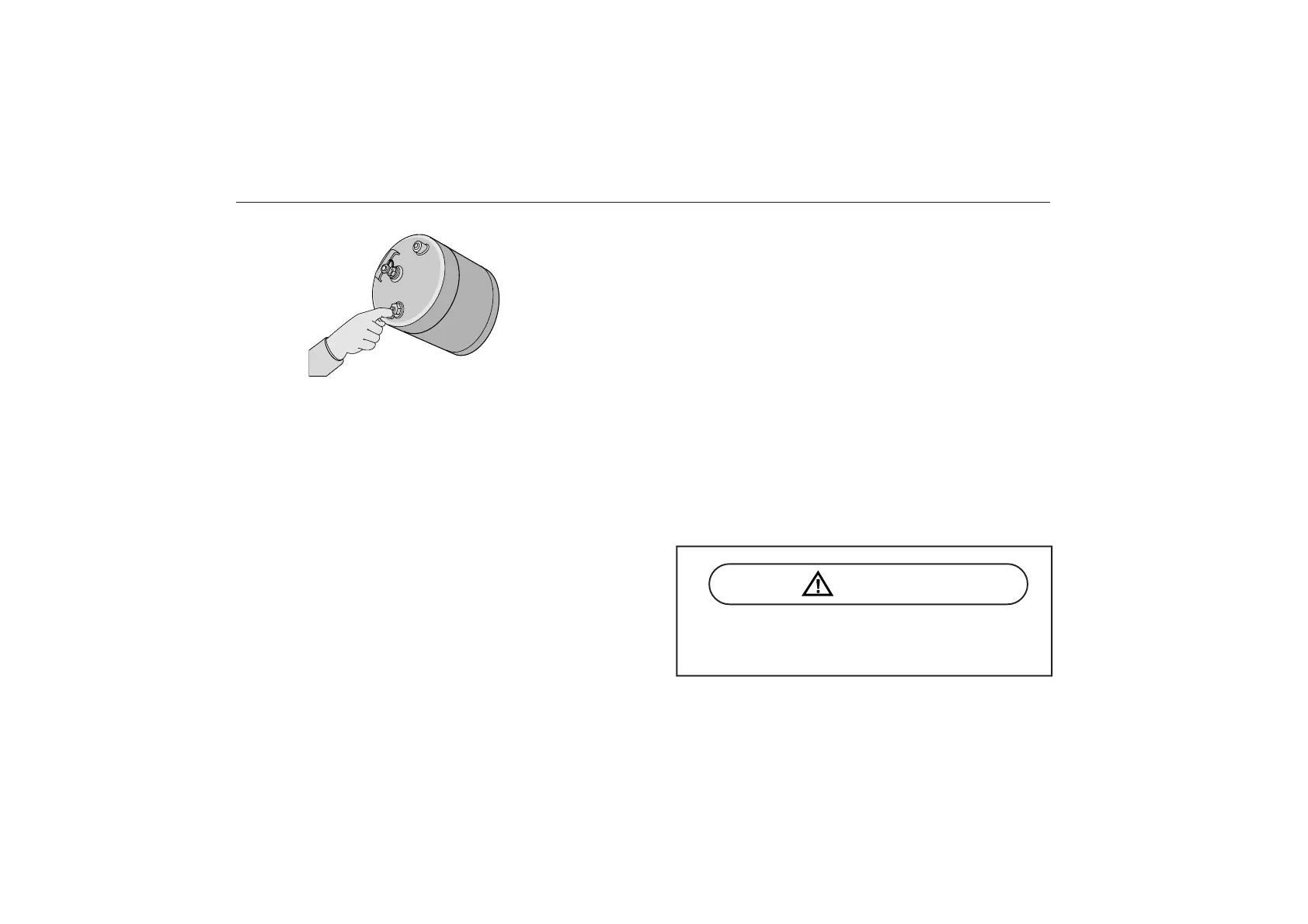

The compressed air tanks are equipped with manual drain

valves. The valves are opened by pulling the ring sideways.

The primary tank should be drained regularly to enable in-

spection of the compressor and air dryer. When the primary

tank is drained regularly there is less risk of damage or ac-

cidents due to defects in the compressor or air dryer. Feel

the air current with your hand! The air should feel dry.

Please note that the purpose of draining is to establish if

there is damp or oil in the compressed air.

Oil found in the air is a sign of damage to the compressor.

Oil found in the air from the compressor also destroys the

drying agent in the air dryer.

If damp or oil is found the drying agent reservoir should be

changed and the other compressed air tanks drained.

Make also sure that the bus is not filled with insufficiently dry

air from for example a ramp or the garage air system.

For maximum safety – drain the primary tank often!

If there is a risk of freezing, the primary tank should be

drained daily.

Damp air in the compressed air system means that

there is a large risk for brake drop out due to the brake

valves freezing in cold weather.

Warning!

Loading...

Loading...