6Operating Tests DBW 2010 / 2016

602

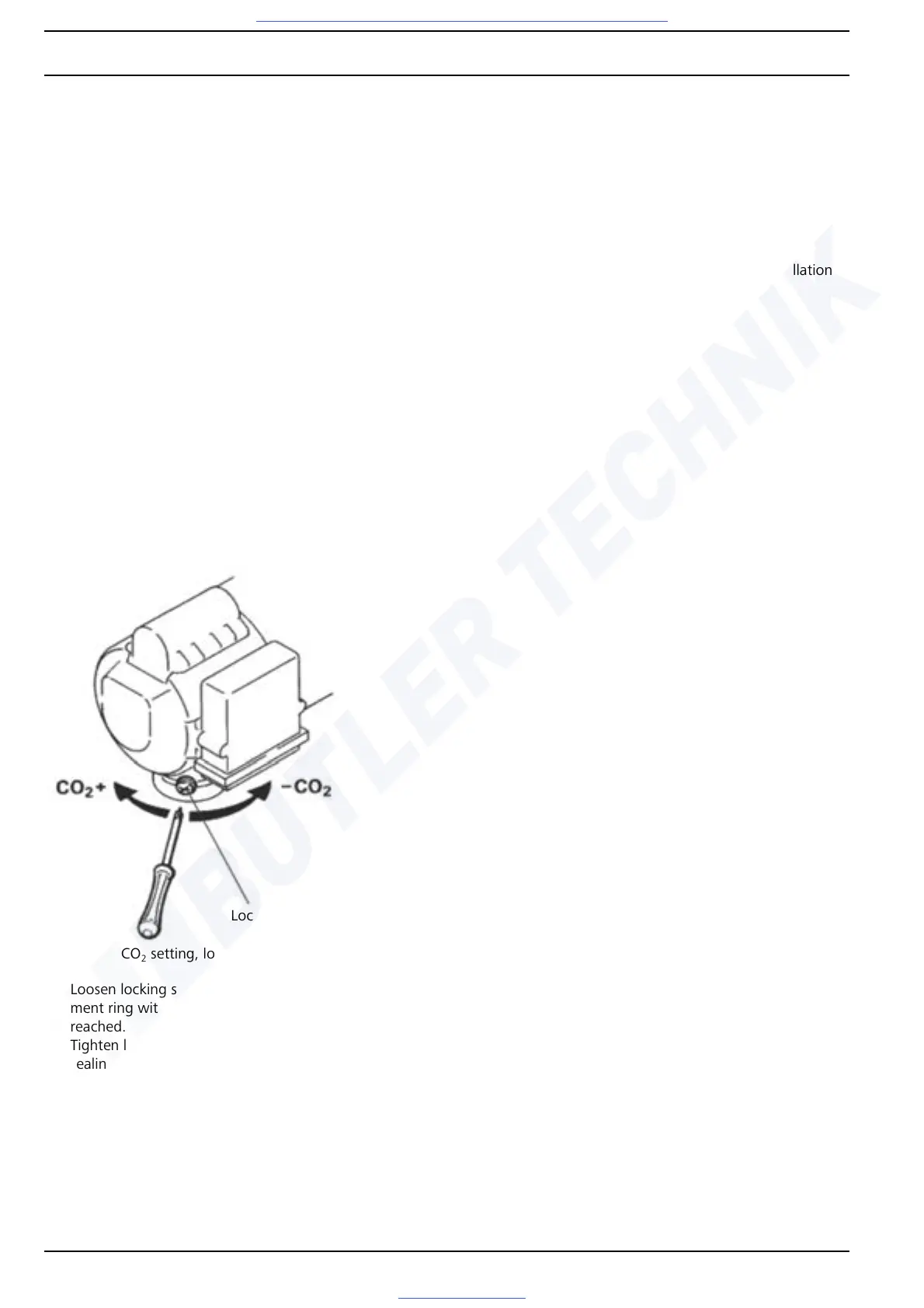

– Loosen locking screw (see Fig. 604) and move adjust-

ment ring with locking screw until setpoint value is

reached.

– Tighten locking screw to 1.0 + 0.5 Nm and lock with

sealing paint.

NOTE

The CO

2

setting is dependent on the fuel (viscosity) and the

geodetic altitude (0.1 % per 100 m).

If the CO

2

value cannot be properly set, proceed as follows:

– Check burner head for damage and replace if necessary

– Check pressure of fuel pump and replace pump if neces-

sary

– Replace nozzle

– Measure speed of burner motor

– Check cable passage grommets for proper installation

Fig. 603 CO

2

setting DBW 2016 (values not available)

Fig. 604 CO

2

setting, locking screw

Loading...

Loading...