7-35

Power unit

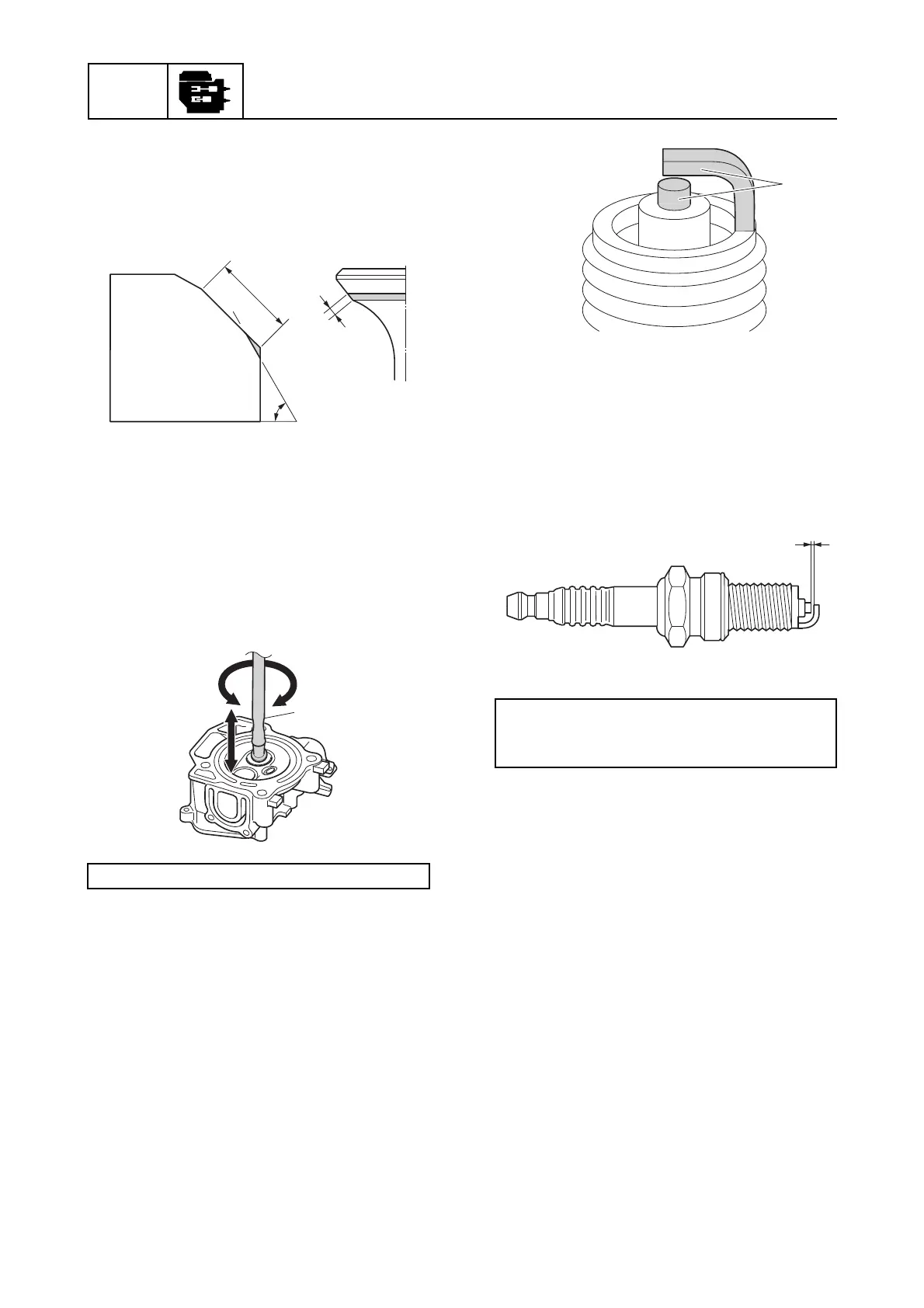

• If the valve seat contact area is too narrow

and situated near the bottom edge of the

valve face, cut the bottom edge of the valve

seat using a 60° cutter to center the area,

and then set its width using a 45° cutter.

b Previous contact width

7. After refacing the contact width of the

valve seat to specification, apply a thin,

even layer of lapping compound onto the

valve seat, and then lap the valve using

the special service tool a. NOTICE: Do

not get the lapping compound on the

valve stem and valve guide.

8. Recheck the valve seat contact area of

the valve. See “Checking the valve seat”

(7-32).

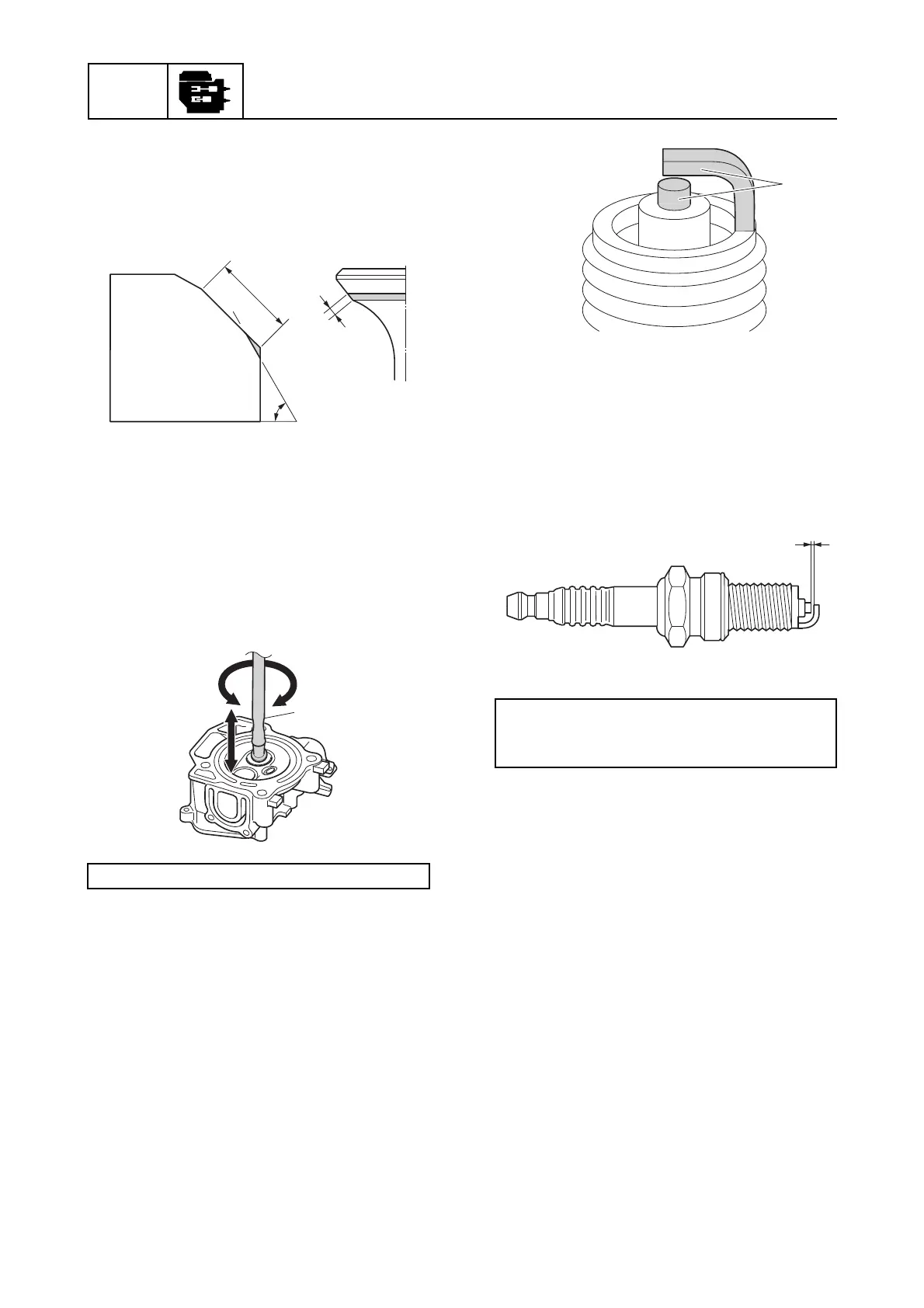

Checking the spark plug

1. Clean the electrodes a using a spark

plug cleaner.

2. Check the spark plug. Replace if the

electrodes are eroded, there is carbon or

other deposits.

3. Check the spark plug gap b. Replace if

out of specification.

Checking the thermostat cover

anode

1. Check the anode. Replace if eroded.

Clean if there is grease, oil, or scales.

NOTICE: Do not apply grease, oil, or

paint to the anode.

Checking the thermostat

1. Suspend the thermostat in a container of

water.

2. Place a thermometer in the water and

slowly heat the water.

Valve lapper a: 90890-04101

60˚

b

a

Specified spark plug: CR6HSB (NGK)

Spark plug gap b:

0.6–0.7 mm (0.024–0.028 in)

Loading...

Loading...