7-43

Power unit

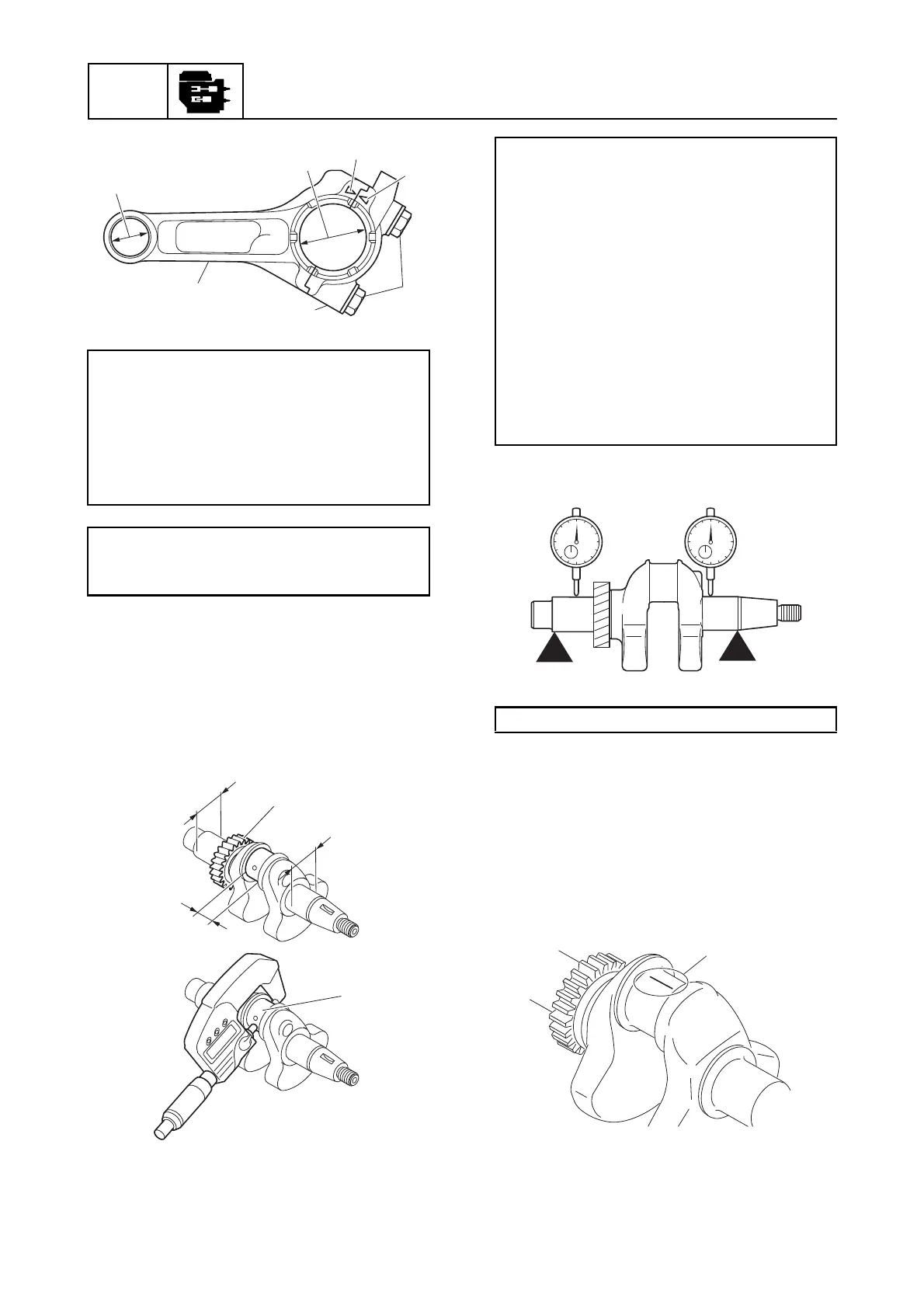

Checking the crankshaft

1. Check the crankshaft gear a. Replace

the crankshaft if damaged or worn.

2. Measure the crankshaft journal diameter

b and c, crankpin diameter d, and

crankpin width e.

3. Measure the crankshaft runout.

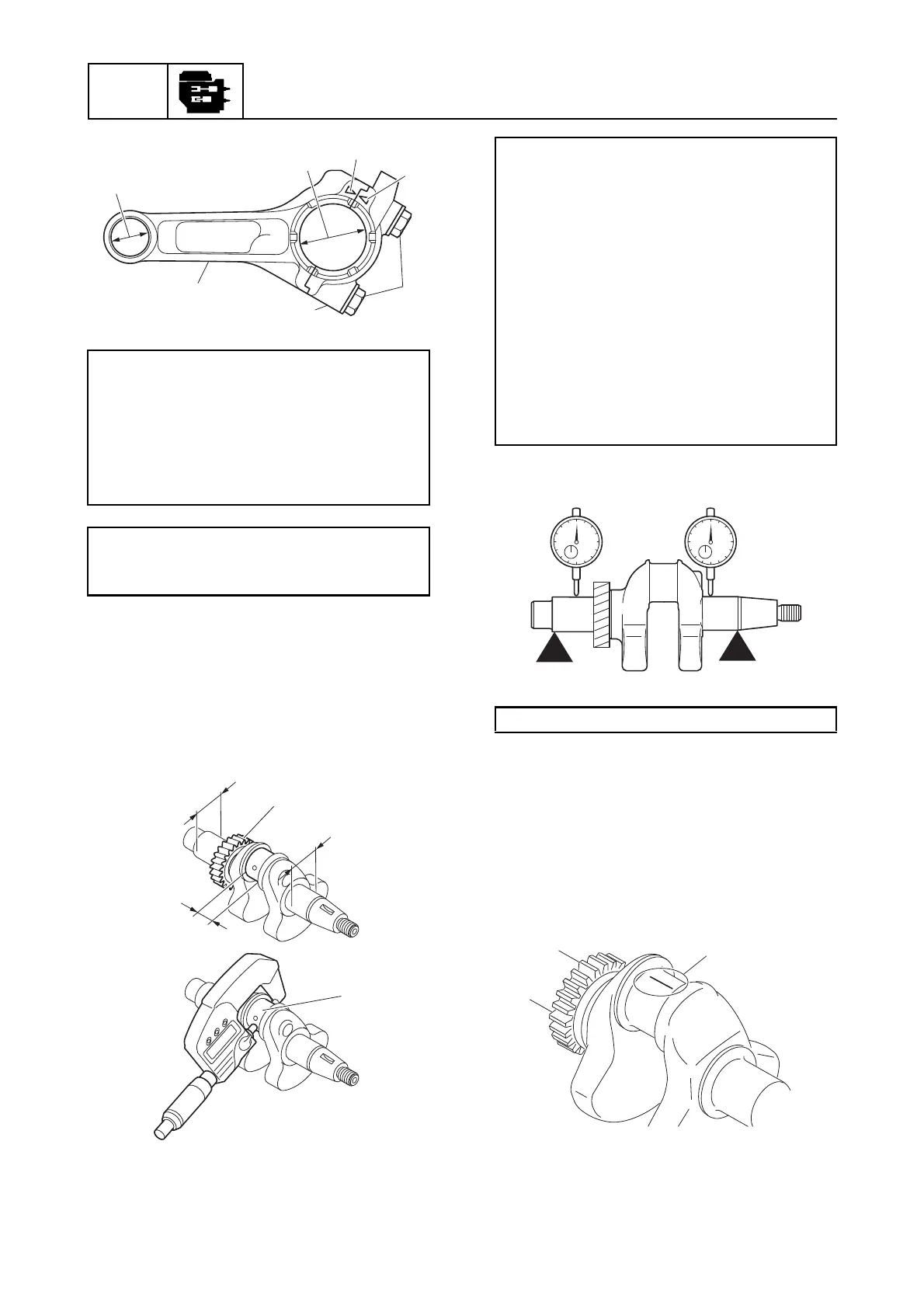

Checking the connecting rod oil

clearance

1. Clean the connecting rod, connecting rod

cap, and crankpin.

2. Place a piece of Plastigauge (PG-1) onto

the crankpin a, parallel to the

crankshaft.

Connecting rod small end inside diameter

e:

15.015–15.029 mm

(0.5911–0.5917 in)

Connecting rod big end inside diameter f:

28.000–28.015 mm

(1.1024–1.1030 in)

Connecting rod cap bolt a:

1st: 6 N·m (0.6 kgf·m, 4.4 ft·lb)

2nd: 12 N·m (1.2 kgf·m, 8.9 ft·lb)

e

a

f

a

c

b

d

e

c

b

d

a

Crankshaft journal diameter (cylinder block

side) b:

24.980–24.993 mm

(0.9835–0.9840 in)

Crankshaft journal diameter (crankcase

side) c:

24.982–24.994 mm

(0.9835–0.9840 in)

Crankpin diameter d:

27.969–27.984 mm

(1.1011–1.1017 in)

Crankpin width e:

21.000–21.100 mm

(0.8268–0.8307 in)

Crankshaft runout: 0.020 mm (0.0008 in)

a

Loading...

Loading...