7-44

Cylinder block

0

1

2

3

4

5

6

7

8

9

10

A

Do not place the Plastigauge (PG-1) over the

oil hole in the crankpin of the crankshaft.

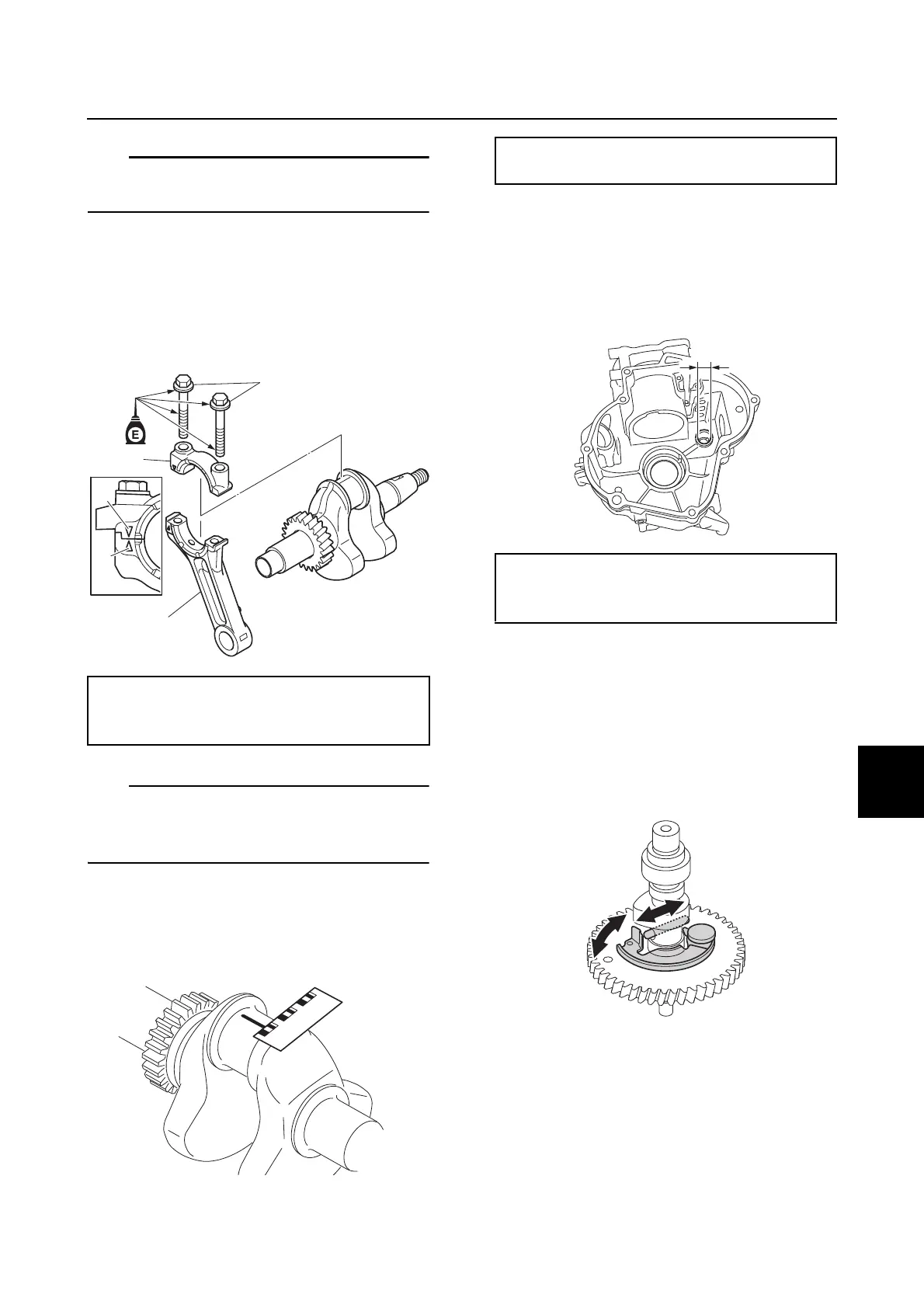

3. Install the connecting rod cap b by

aligning the mark c on the connecting

rod d and the mark e on the connecting

rod cap b, and then tighten the

connecting rod cap bolts a to the

specified torques in 2 stages.

Do not turn the connecting rod until the con-

necting rod oil clearance measurement has

been completed.

4. Remove the connecting rod cap, and

then measure the width of the

compressed Plastigauge (PG-1) on the

crankpin.

Checking the cylinder block

1. Check the cylinder block. Replace if cor-

roded or cracked.

2. Measure the camshaft journal inside

diameter a.

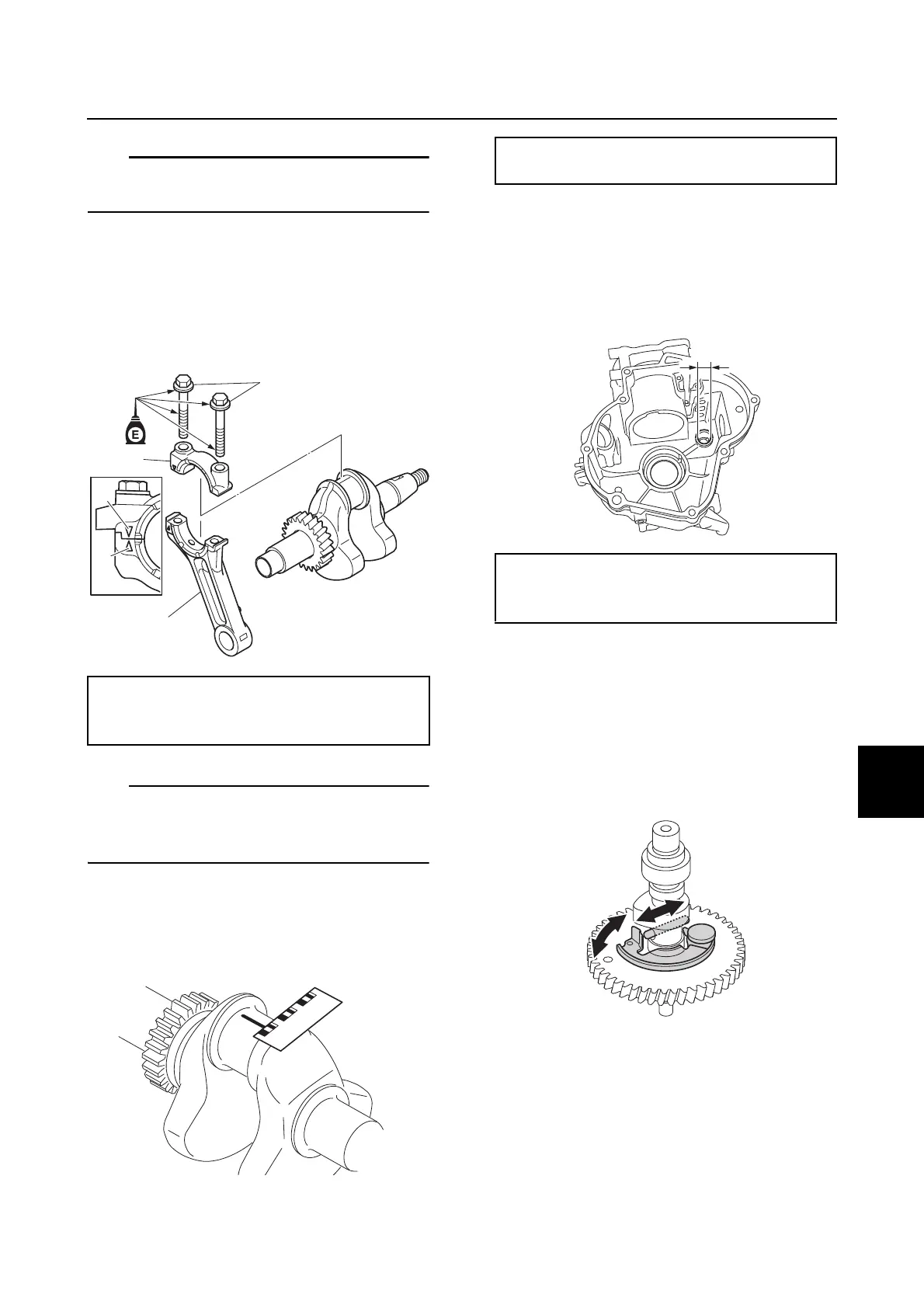

Checking the camshaft

1. Check the camshaft gear. Replace the

camshaft if damaged or worn.

2. Check the decompression actuator.

Replace the camshaft if the

decompression actuator does not

operate smoothly.

3. Measure the cam lobe height a, cam

lobe width b, and fuel pump cam

diameter c.

Connecting rod cap bolt a:

1st: 6 N·m (0.6 kgf·m, 4.4 ft·lb)

2nd: 12 N·m (1.2 kgf·m, 8.9 ft·lb)

Connecting rod oil clearance:

0.016–0.046 mm (0.0006–0.0018 in)

Camshaft journal inside diameter a:

15.000–15.018 mm

(0.5906–0.5913 in)

Loading...

Loading...