FORM NO.:6U6K-B01E-NB-EN

JOHNSON CONTROLS

118

DEFROST CONTROLS

The purpose of any defrost system is to remove frost and ice

from the ambient coils. The adaptive defrost system achieves

this by optimizing the setpoint of defrosts dependent on ambient

temperature and duration with the aim of improving overall unit

efciency. The eld programmable setpoints are:

•

DEFROST INTERVAL (Program range 15 to 120 minutes,

40 as default)

•

DEFROST INITIATION TEMPERATURE DIFFERENCE

(Temperature difference between coil temperature and ambient

temperature; Program range -10 to 0 °C, 7 °C as default)

•

DEFROST TERMINATION TIME (Program range 180 to

600 seconds, 360 seconds as default)

•

DEFROST TERMINATION COIL TEMPERATURE

(Program range 6 to 20 °C, 10 °C as default)

The temperature sensors used are the defrost sensor(s) mounted

on the capillary of ambient coils.

The successful implementation of the adaptive defrost is

dependent on the location of the temperature sensor. The

sensor is factory positioned where in general the frost is most

persistent.

There is one defrost sensor tted on each system of the YMPA

units. Two sensors are tted on dual system units as the defrost

strategy ensures that both systems do not defrost at the same

time, which assists in maintaining some stability to the leaving

water temperature during heat pump mode. Coils defrost

normally when operating in lower ambient temperatures below

+7 °C.

Defrost Interval

The interval is the delay between defrosts within a system and

its value can be set in the range of 15 to 120 minutes with a

recommended setting of 40 minutes.

Defrost Initiation Temperature Difference

The difference between coil temperature and ambient

temperature indirectly indicates the formation of frost at the

surface of the coil. The value can be set in the range of -10 to 0

°C with a recommended setting of 7 °C.

If the temperature difference is below the initiation value, a

defrost cycle is initiated. The system mode solenoid changes

to the cooling mode. During defrost the low pressure cut-out is

ignored. The compressors within the system will start with a 30

seconds delay.

The fan for the system will stop, except when the discharge

pressure rises above 34 BARG and does not fall below

28 BARG. In this case the fan will run at xed speed. The other

system continues to operate in the heat pump mode and the unit

continues to be controlled to the heating setpoint.

Defrost Termination

When the frost is removed, the coil temperature rises rapidly

and soon reaches the termination temperature of 10°C. The

compressors will be powered off and heat loading will be

enabled.

If coil temperature is still under the termination temperature

in 360 seconds, the defrost process will also terminate. Other

protective exit criteria include discharge temperature, discharge

pressure and unit outlet liquid temperature.

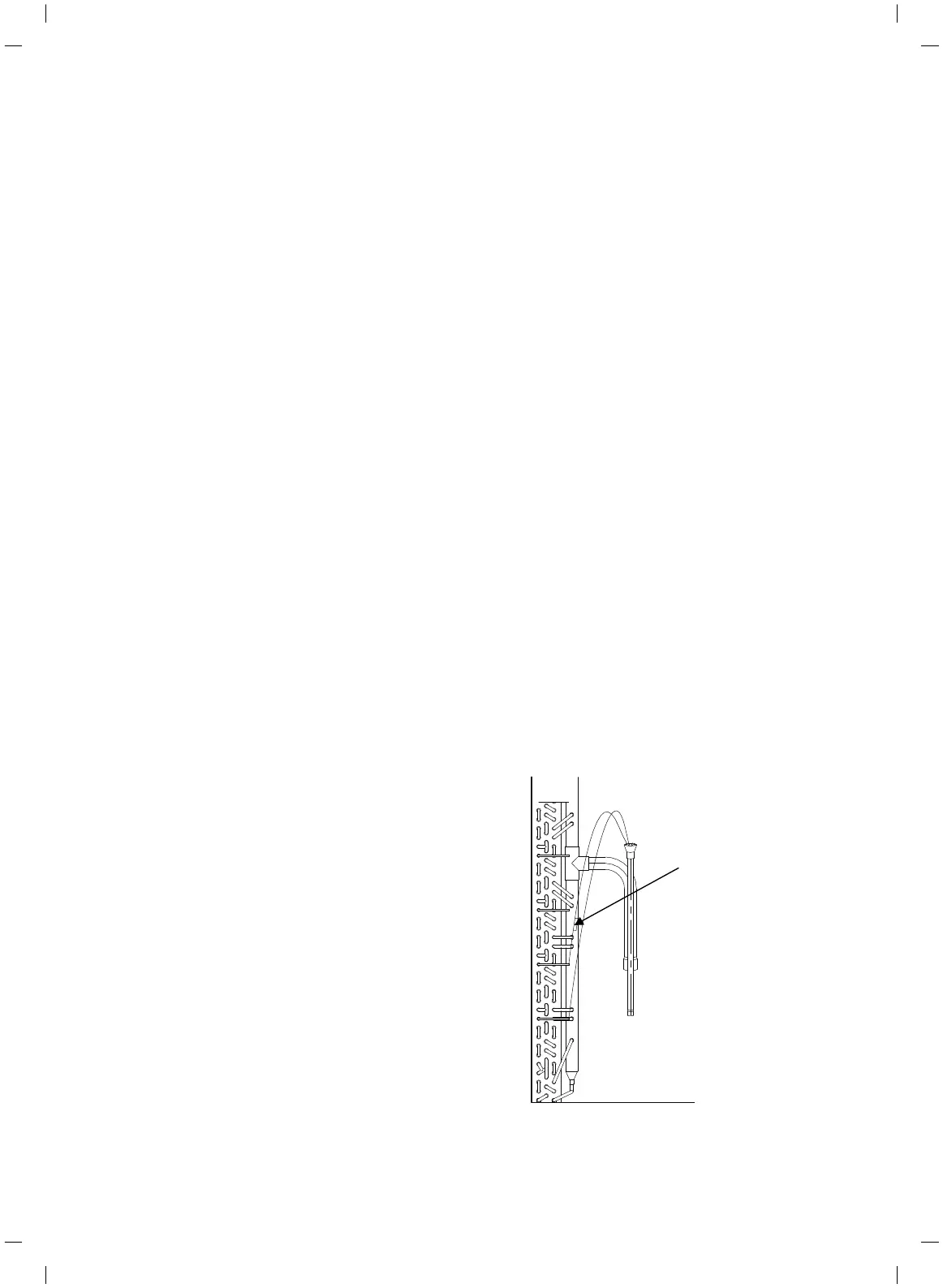

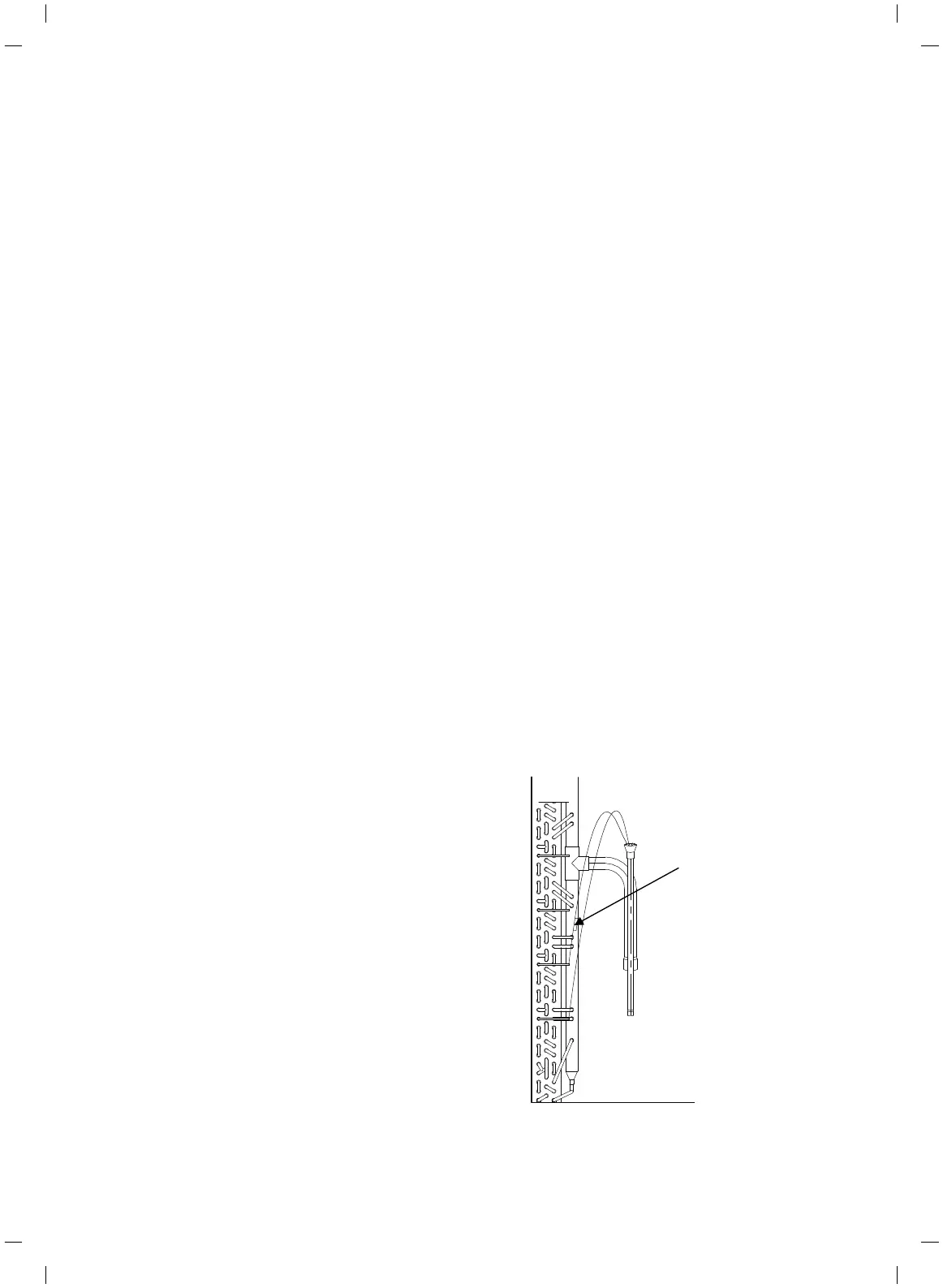

Defrost Sensor Mounting and Position

The Coil Defrost Temperature sensors are mounted on the left

hand side of the V-shaped coils on a system looking from the

side-view. Within the coil the sensor is on the second capillary

counted from the bottom. The sensor is correctly positioned

during manufacture but may need to be re-positioned at site,

to either suit site operating conditions or optimize the defrost

cycle time.

Defrost Sensor

FIGURE 45 – LOCATIONS OF DEFROST SENSOR

SECTION 9 – UNIT OPERATION

Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz

Loading...

Loading...