Planning the cabinet installation

26

Grounding of mounting structures

Make sure any cross-members or shelves on which components are mounted are

properly grounded and the connecting surfaces left unpainted. The drive module will

be grounded to the cabinet frame via its fastening screws.

Busbar material and joints

Tin-plated copper is recommended but aluminium can also be used.

Before joining aluminium busbars, remove the oxide layer and apply suitable anti-

oxidant joint compound.

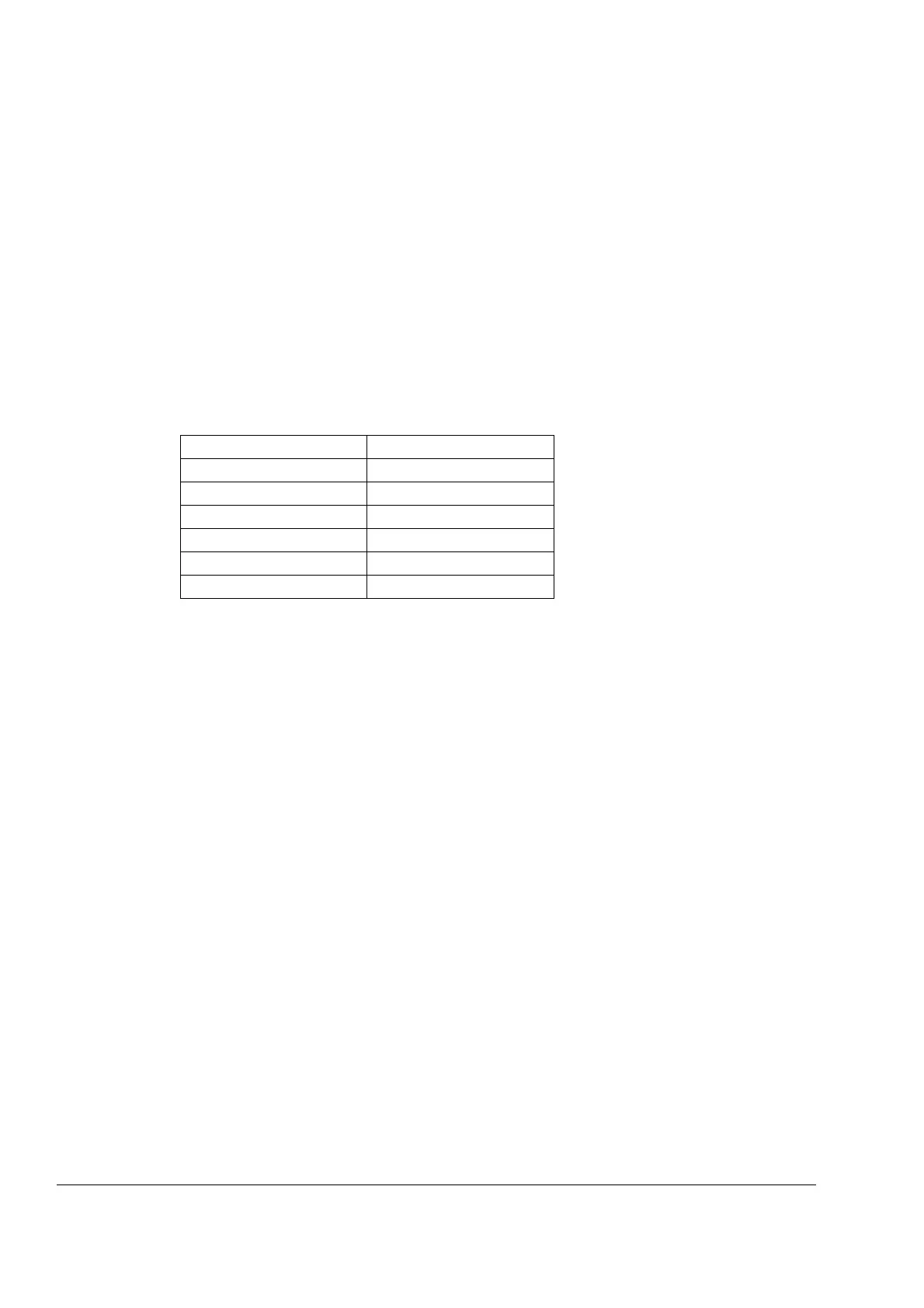

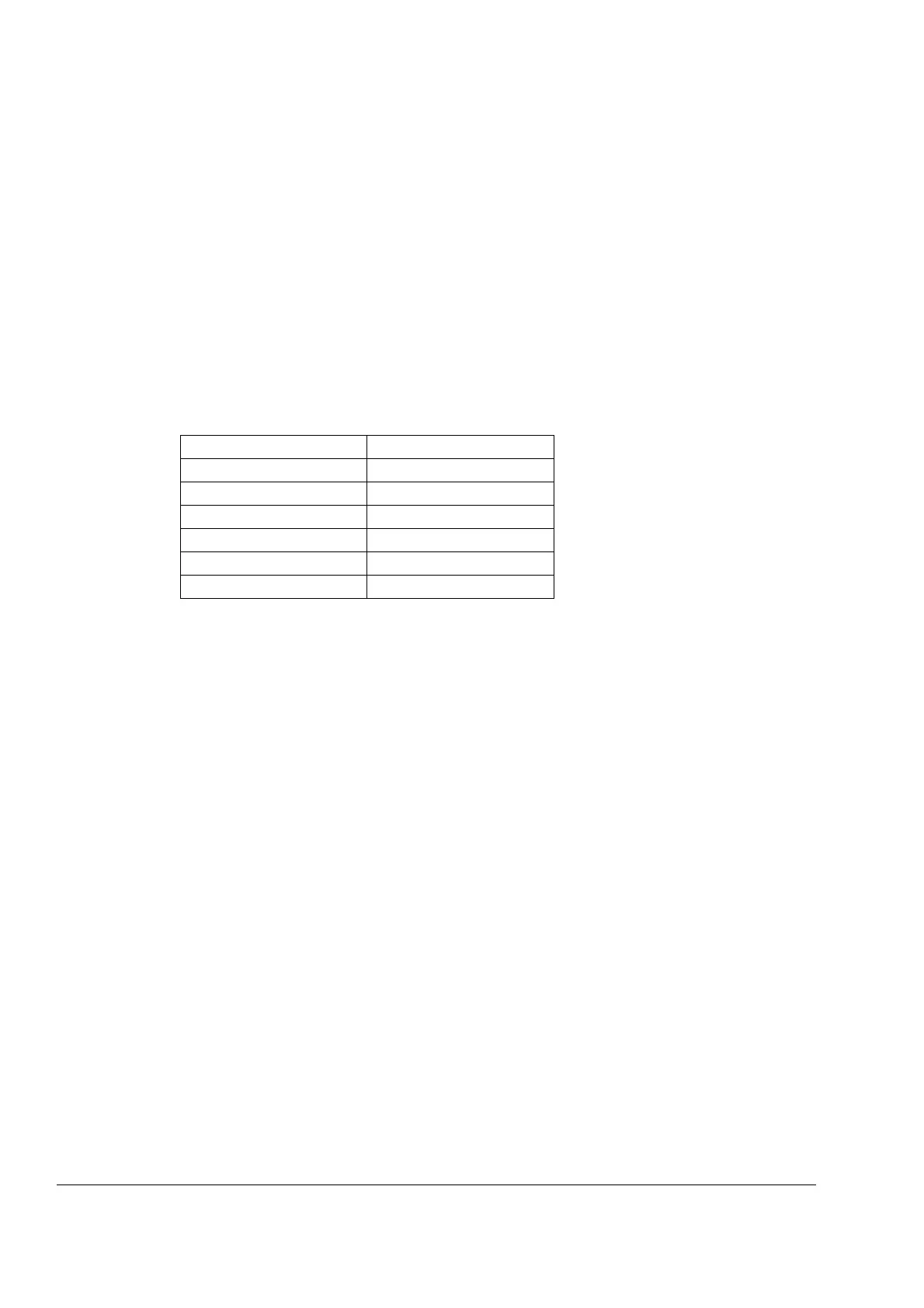

Tightening torques

The following table applies to grade 8.8 screws (with or without joint compound).

Cabinet cooling

The installation site must be sufficiently ventilated.

The cabinet must have enough free space for the components to ensure sufficient

cooling. Observe the minimum clearances given for each component.

The heat dissipated by cables and other additional equipment must also be

ventilated.

The air inlets and outlets must be equipped with gratings that

• guide the air flow

• protect against contact

• prevent water splashes from entering the cabinet.

Screw size Torque

M5 3.5 N·m (2.6 lbf·ft)

M6 9 N·m (6.6 lbf·ft)

M8 20 N·m (14.8 lbf·ft)

M10 40 N·m (29.5 lbf·ft)

M12 70 N·m (52 lbf·ft)

M16 180 N·m (133 lbf·ft)

Loading...

Loading...