INSTALLATION

TUBING CONNECTIONS

3 - 9

Positioners equipped with manifolds have three secondary filters

as part of the unit. If the filters become clogged, they can be

cleaned (by removing and reverse flushing with air or liquid) or

replaced (refer to Table 1-7 for kit number). Refer to Section 7 for

manifold filter replacement procedures.

Air Supply Quality (Recommended)

For long-term, trouble free operation, it is recommended that the

supply air be of instrument quality and conform to the ANSI/

ISA-7.0.01-1996 standard that includes the following:

• The pressure dew point as measured at the dryer outlet shall

be at least 10

o

C (18

o

F) below the minimum temperature to

which any part of the instrument air system is exposed. The

pressure dew point shall not exceed 4

o

C (39

o

F) at line pres-

sure.

• The oil content should be as close to zero as possible and,

under no circumstances, shall it exceed one (1) ppm w/w or

v/v.

• Instrument air should be free of corrosive contaminants and

hazardous gases, which could be drawn into the instrument air

supply.

In addition, the particle size in the supply line should not be

greater that 3.0 microns.

Tubing Connections

1. Connect the required air supply to connection S (Fig. 3-9).

NOTE: Use liquid or paste pipe sealant to seal the connection.

Maximum torque for ¼-NPT fittings is 13.6 Nm (10 ft-lbs).

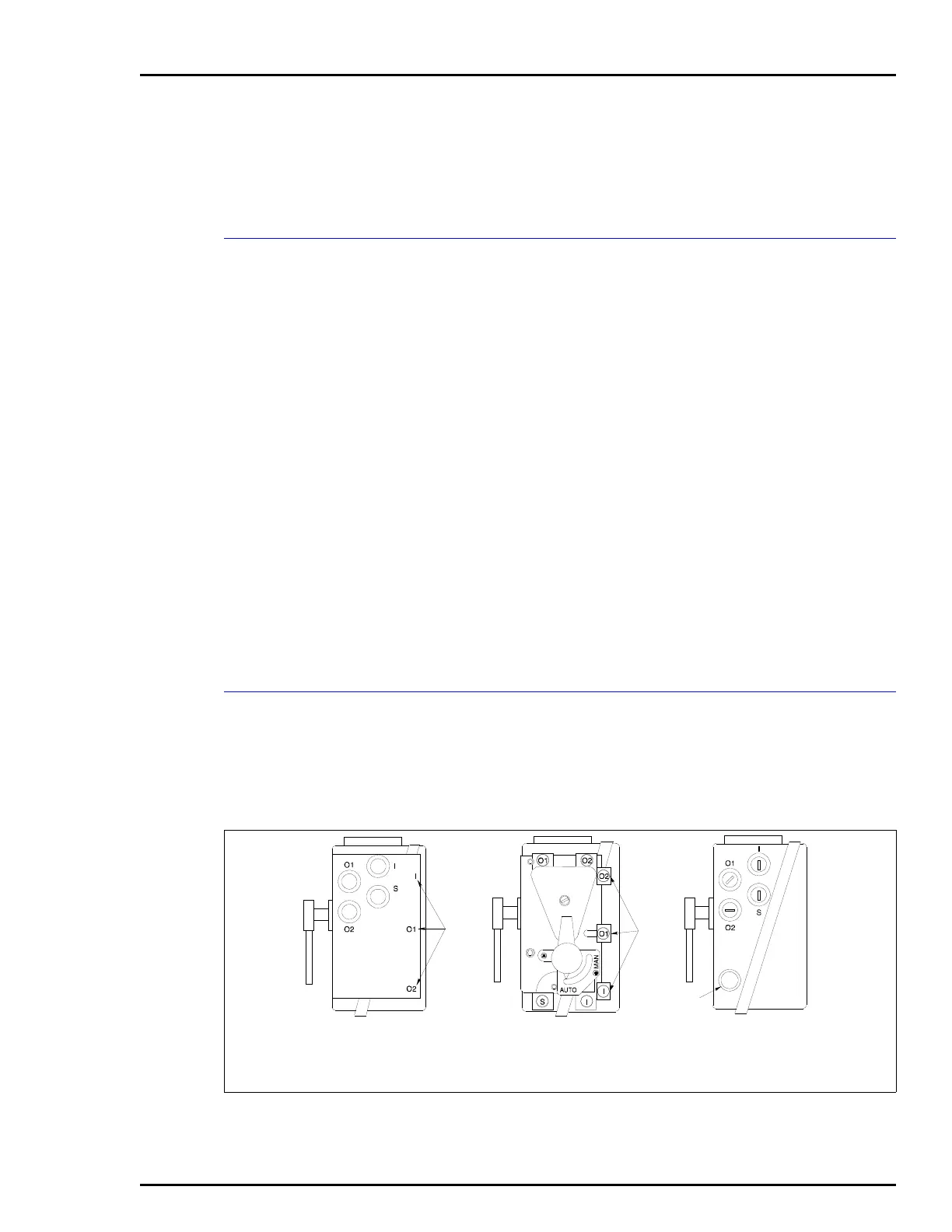

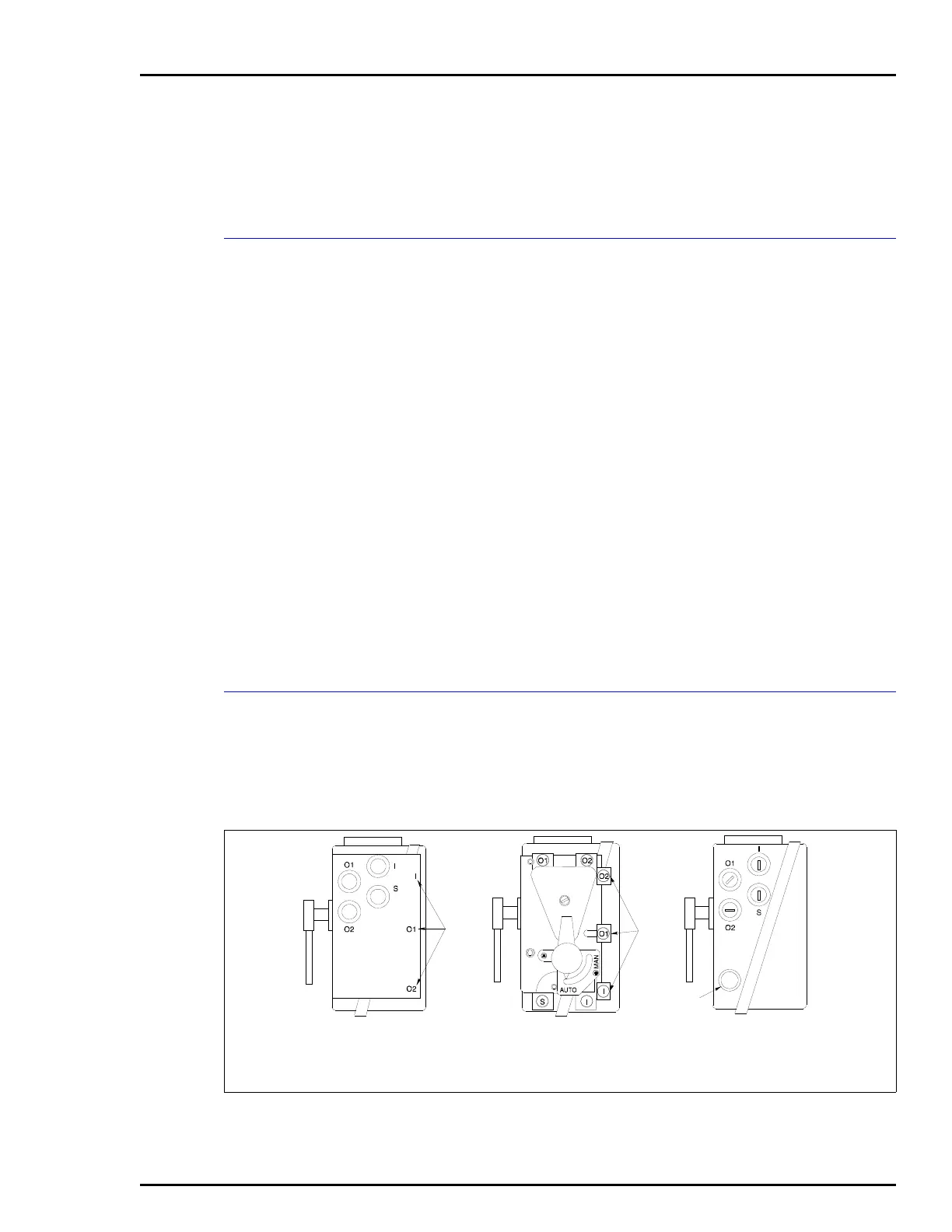

Figure 3-9. Port Locations

T00806A

VIEW WITH GAGE

BLOCK (AV???3???)

VIEW WITH MANIFOLD

(AV???1??? OR

AV???2???)

VIEW WITHOUT

MANIFOLD

(AV???0???)

GAGE

PORTS

GAGE

PORTS

CONDUIT

CONNECTION

Loading...

Loading...