CAM CHARACTERIZATION

CAM SELECTION

C - 3

Table C-1 relates the percentage of control signal to the corre-

sponding pressure values of the input signal. Table C-2 relates the

percentage of control signal to input (current) and output (pounds

per square inch gage) values of the I/P converter.

CAM SELECTION

In a system involving only a single actuator or cylinder, the B cam

is probably satisfactory and should be tried first. However, one of

the other cams may provide a more stable control over a wide

range of operation within a given proportional band gain adjust-

ment on the controller. Where the actuator or cylinder is part of a

complex control system, the three standard cams A, B and C pro-

vide a choice of control characteristics. The cam, in conjunction

with a span adjustment, are likely to meet the control characteris-

tic required for the system.

Steps is selecting a standard cam for a particular application are:

1. With the B (linear) cam in place, determine and plot the actual

controlled medium versus piston (or valve) position characteristic

by manually adjusting valve position and measuring the controlled

medium (Fig. C-4).

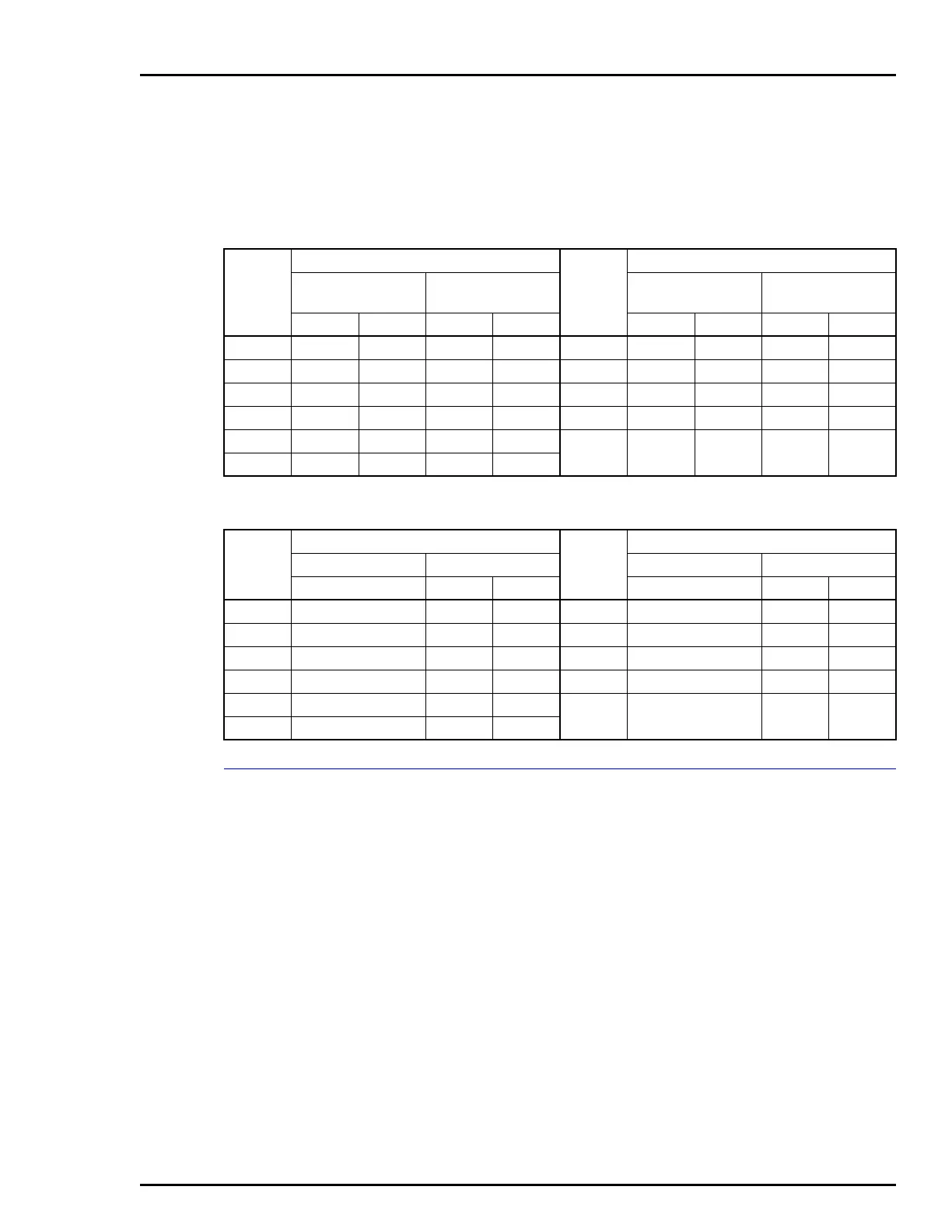

Table C-1. Control Signal Pressure Conversions (AV1)

% of

Control

Signal

Control System Spans

% of

Control

Signal

Control System Spans

20.7 to 103.4 kPa

(3.0 to 15.0 psig)

20.7 to 186.2 kPa

(3.0 to 27.0 psig)

20.7 to 103.4 kPa

(3.0 to 15.0 psig)

20.7 to 186.2 kPa

(3.0 to 27.0 psig)

kPa psig kPa psig kPa psig kPa psig

0 20.7 3.0 20.7 3.0 60 70.3 10.2 120.0 17.4

10 29.0 4.2 37.3 5.4 70 78.6 11.4 136.6 19.8

20 37.2 5.4 53.8 7.8 80 86.9 12.6 153.1 22.2

30 45.5 6.6 70.4 10.2 90 95.2 13.8 169.7 24.6

40 53.8 7.8 86.9 12.6 100 103.4 15.0 186.2 27.0

50 62.1 9.0 103.5 15.0

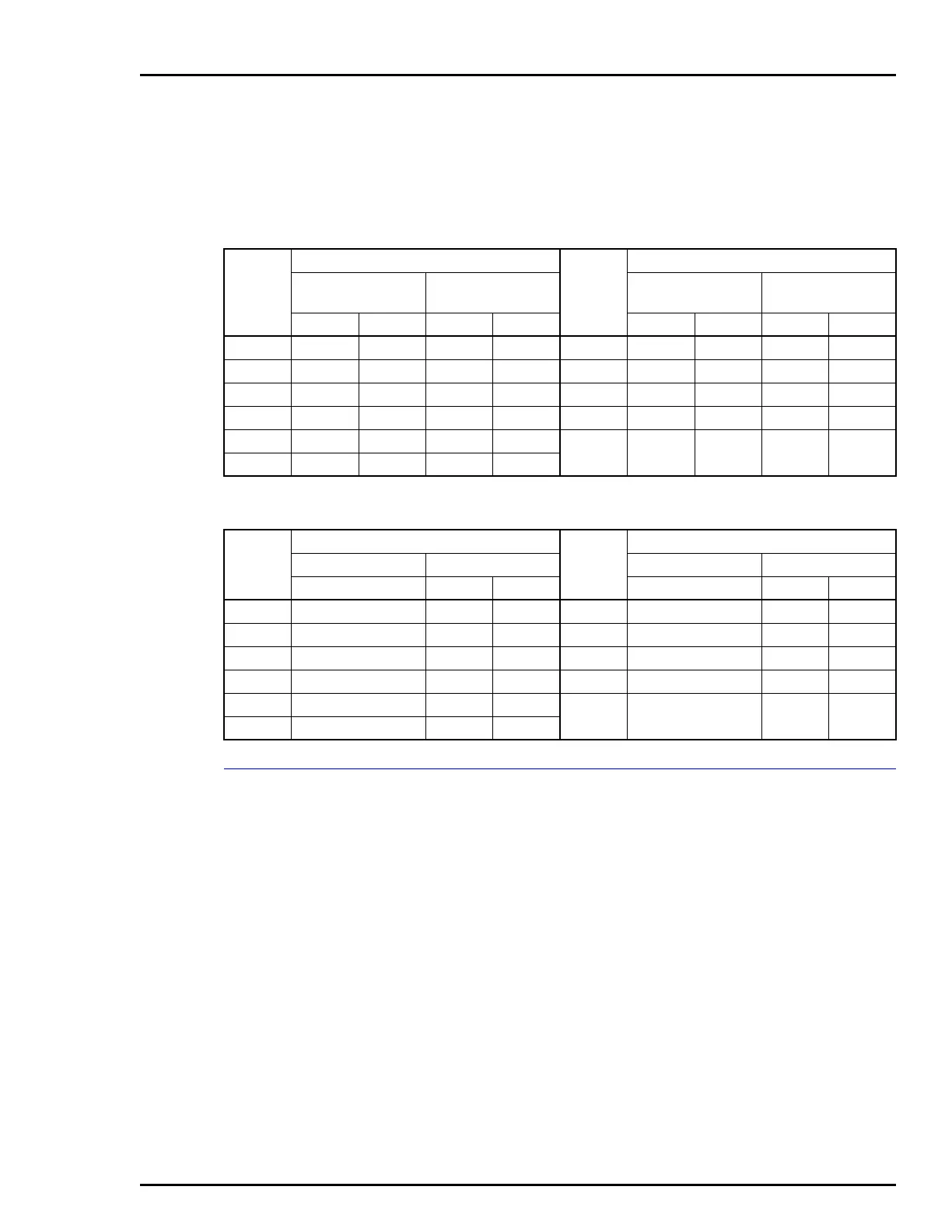

Table C-2. Input to Output I/P Converter Relationships (AV2)

% of

Control

Signal

I/P Converter

% of

Control

Signal

I/P Converter

Input Output Input Output

mA kPa psig mA kPa psig

0 4.0 20.7 3.0 60 13.6 70.3 10.2

10 5.6 29.0 4.2 70 15.2 78.6 11.4

20 7.2 37.2 5.4 80 16.8 86.9 12.6

30 8.8 45.5 6.6 90 18.4 95.2 13.8

40 10.4 53.8 7.8 100 20.0 103.4 15.0

50 12.0 62.1 9.0

Loading...

Loading...