POSITION TRANSMITTERS

CALIBRATION

A - 4

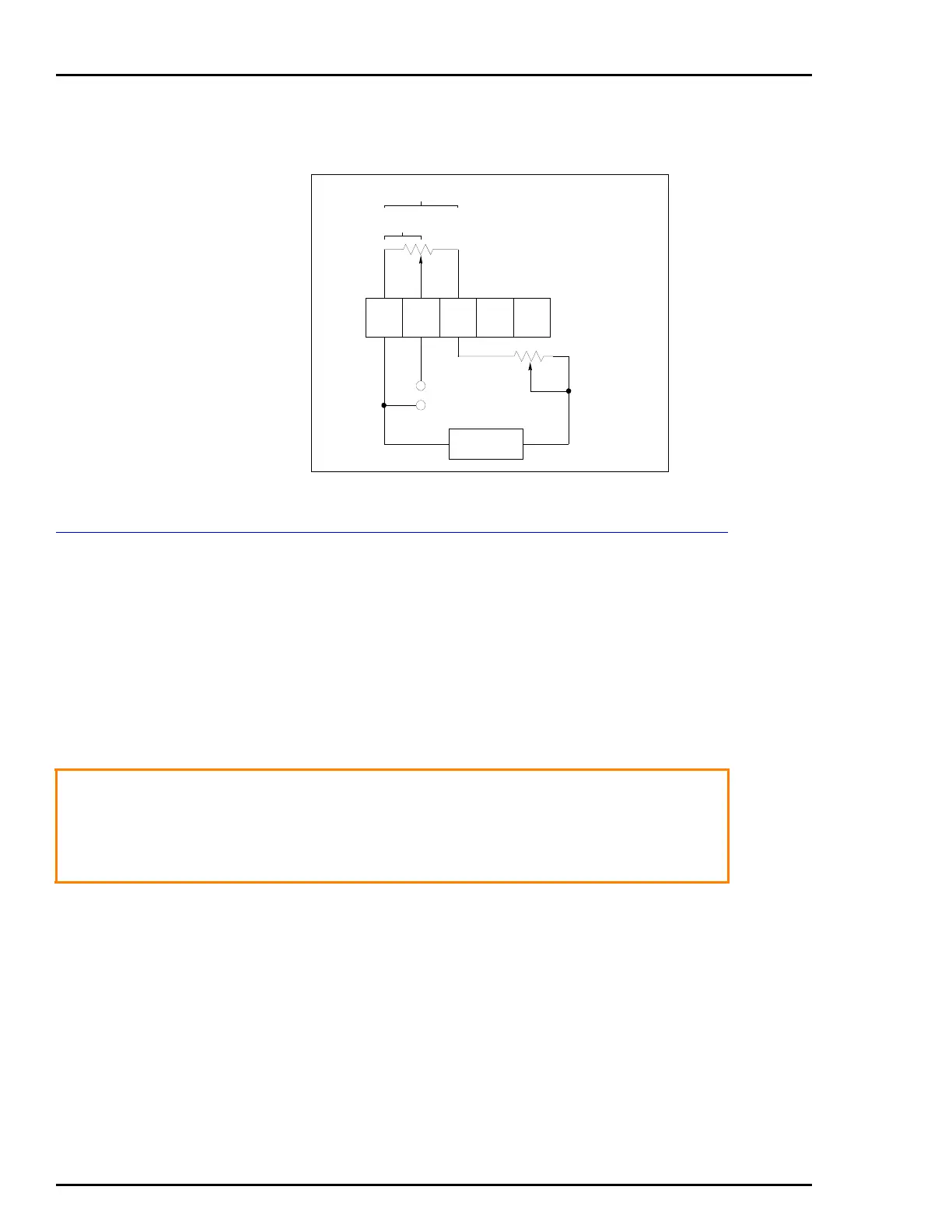

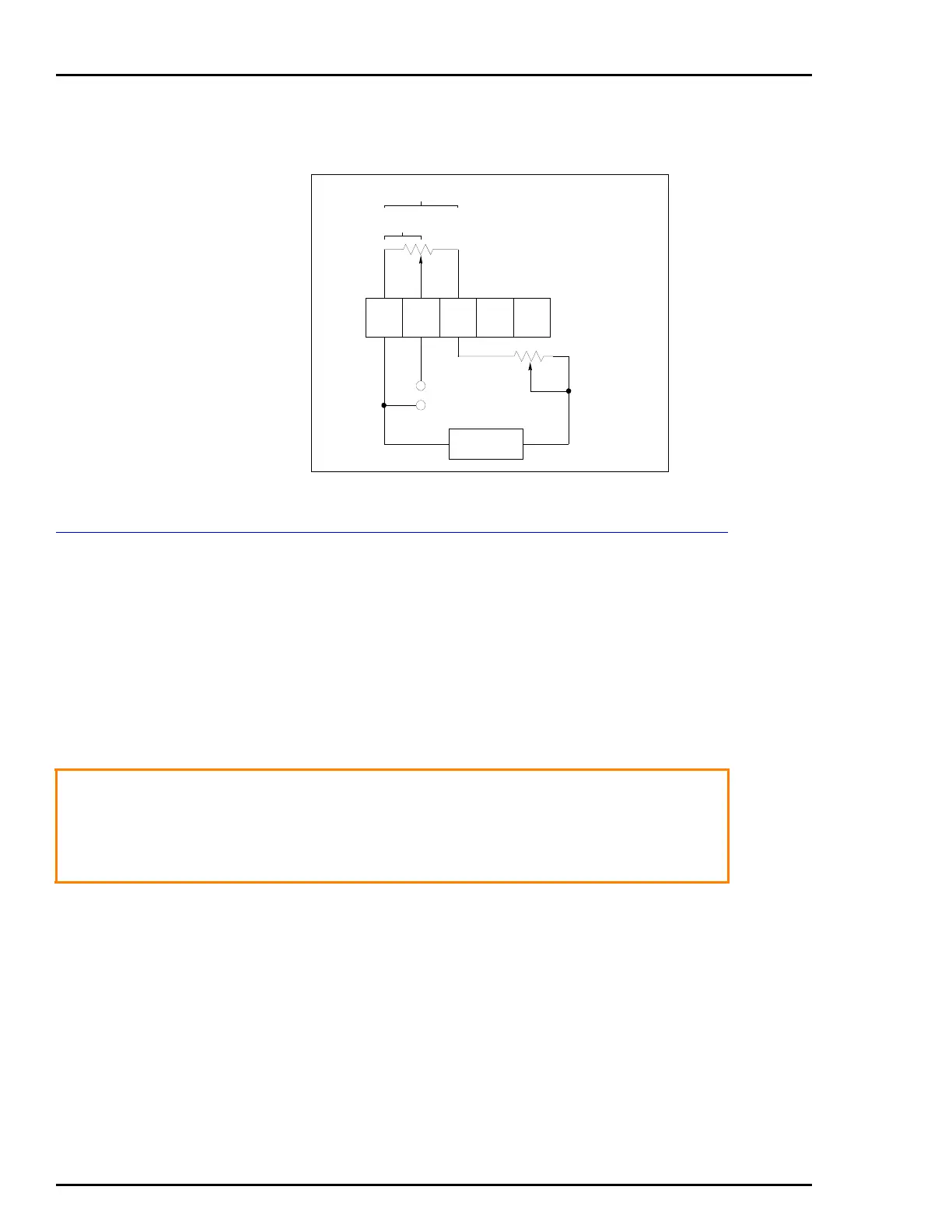

tolerance of the potentiometer. Figure A-2 is a schematic diagram

of this application example.

CALIBRATING THE POTENTIOMETRIC EXAMPLE

The calibration information is based on the application put forth in

POTENTIOMETRIC APPLICATION EXAMPLE.

1. Move the actuator to the 0% output position.

2. Remove the field wiring from TB1-1, TB1-2 and TB1-3. Using

an ohmmeter, measure the resistance between TB1-1 and TB1-2.

If the reading is 200, ±20 Ω, remove the ohmmeter and proceed to

Step 3. Otherwise continue with Step 2.

a. Remove the cam by removing the screw, flag, nut and

washer (Fig. A-3 and Table A-1).

b. Loosen the set screw on the hub of the small gear using a

-in. Allen wrench (Fig. A-3 and Table A-1).

c. Use a screwdriver to adjust the shaft on the potentiometer

until the ohmmeter reads 200, ±20 Ω. While adjusting the

resistance, hold the gears and cam shaft stationary so rotation

does not occur. Only the potentiometer shaft should move

while adjusting the resistance.

Figure A-2. Schematic Diagram

TB1

2000 ±20%

Ω

2380

NOMINAL

ADJUSTMENT

Ω

OUTPUT

24 VDC

T00787A

200-912.8

Ω

12345

+

+

–

–

WARNING

The pneumatic supply pressure must be turned off before

removing the positioning cam. The final control element will

go to one end of the stroke and can cause a process upset.

Some process upsets may cause damage to equipment and

endanger personnel.

Loading...

Loading...