Refitting, SMB unit

Use this procedure to refit the SMB unit.

NoteAction

DANGER

Turn off all:

• electric power supply

• hydraulic pressure supply

• air pressure supply

to the robot, before entering the robot working

area.

1

ELECTROSTATIC DISCHARGE (ESD)

The unit is sensitive to ESD. Before handling the

unit read the safety information in section The

unit is sensitive to ESD on page 33

2

Shown in the figure Location of SMB

unit on page 259.

Connect the battery cable to the SMB unit.

Make sure the lock on the battery cable connect-

or R2.G snaps into place during refitting.

3

Art. no. is specified in Required

equipment on page 259.

Connect all connectors to the SMB board:

R1.SMB1-3, R1.SMB4-6 and R2.SMB

4

Shown in the figure Location of SMB

unit on page 259.

Fit the SMB unit onto the guide pins.5

Secure the SMB unit to the pins with the nuts

and washers.

6

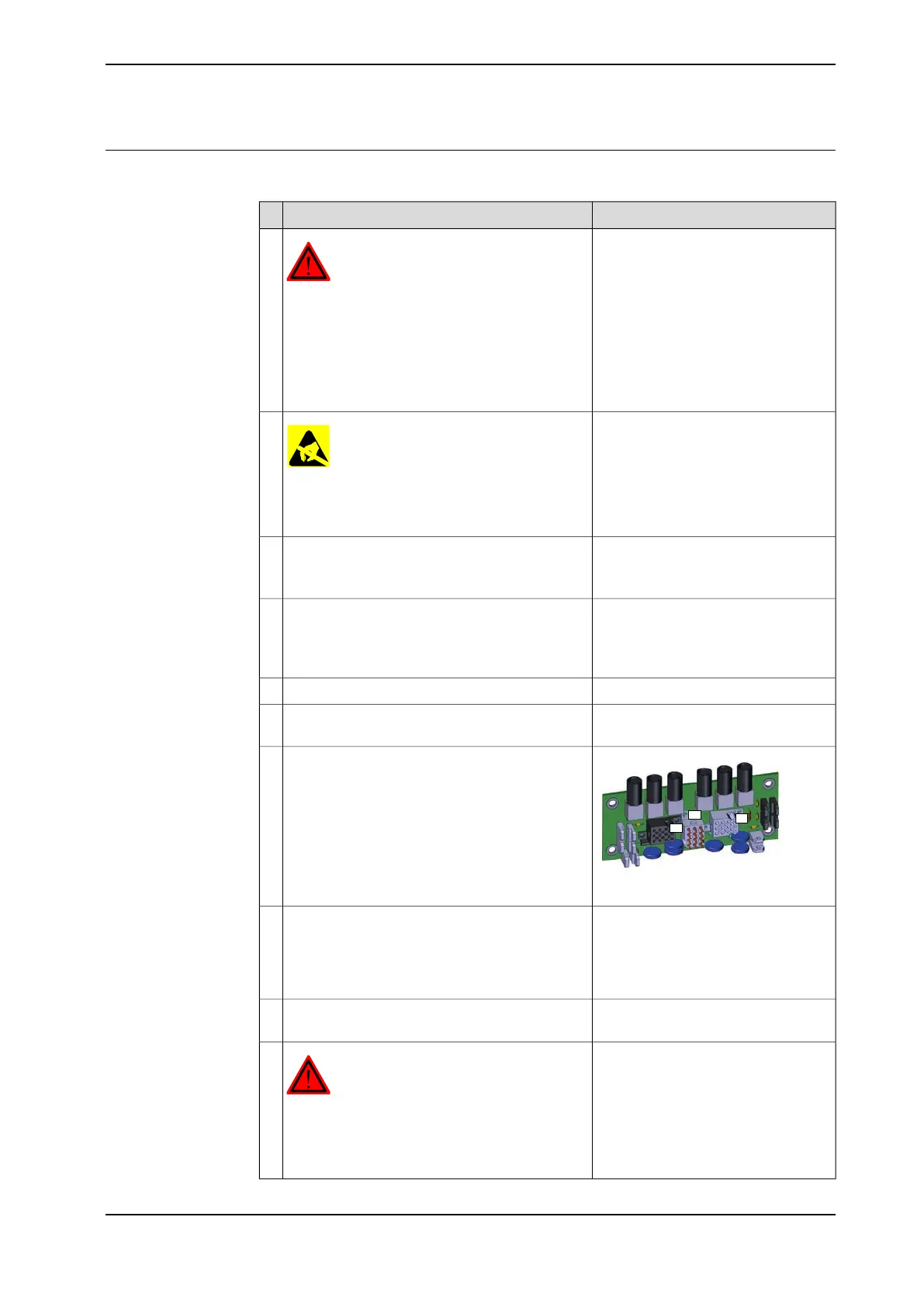

xx1700000978

If disconnected, reconnect the connectors X8,

X9 and X10 to the brake release board.

Be careful not to damage the sockets or pins.

Make sure the connector and its locking arms

are snapped down properly.

7

Shown in the figure Location of SMB

unit on page 259.

Secure the SMB cover with its attachment

screws.

If cabling is used for 7th axis (option), refit the

7th axis connector to the SMB cover and tighten

with 6 Nm.

8

See Updating revolution counters on

page 348.

Update the revolution counter!9

DANGER

Make sure all safety requirements are met when

performing the first test run. These are further

detailed in the section First test run may cause

injury or damage on page 28.

10

Product manual - IRB 6660 261

3HAC028197-001 Revision: S

© Copyright 2007-2018 ABB. All rights reserved.

4 Repair

4.5.1 Replacing the SMB unit

Continued

Loading...

Loading...