Rockwell Automation Publication 22C-UM001J-EN-E - January 2017 165

Application Notes Appendix D

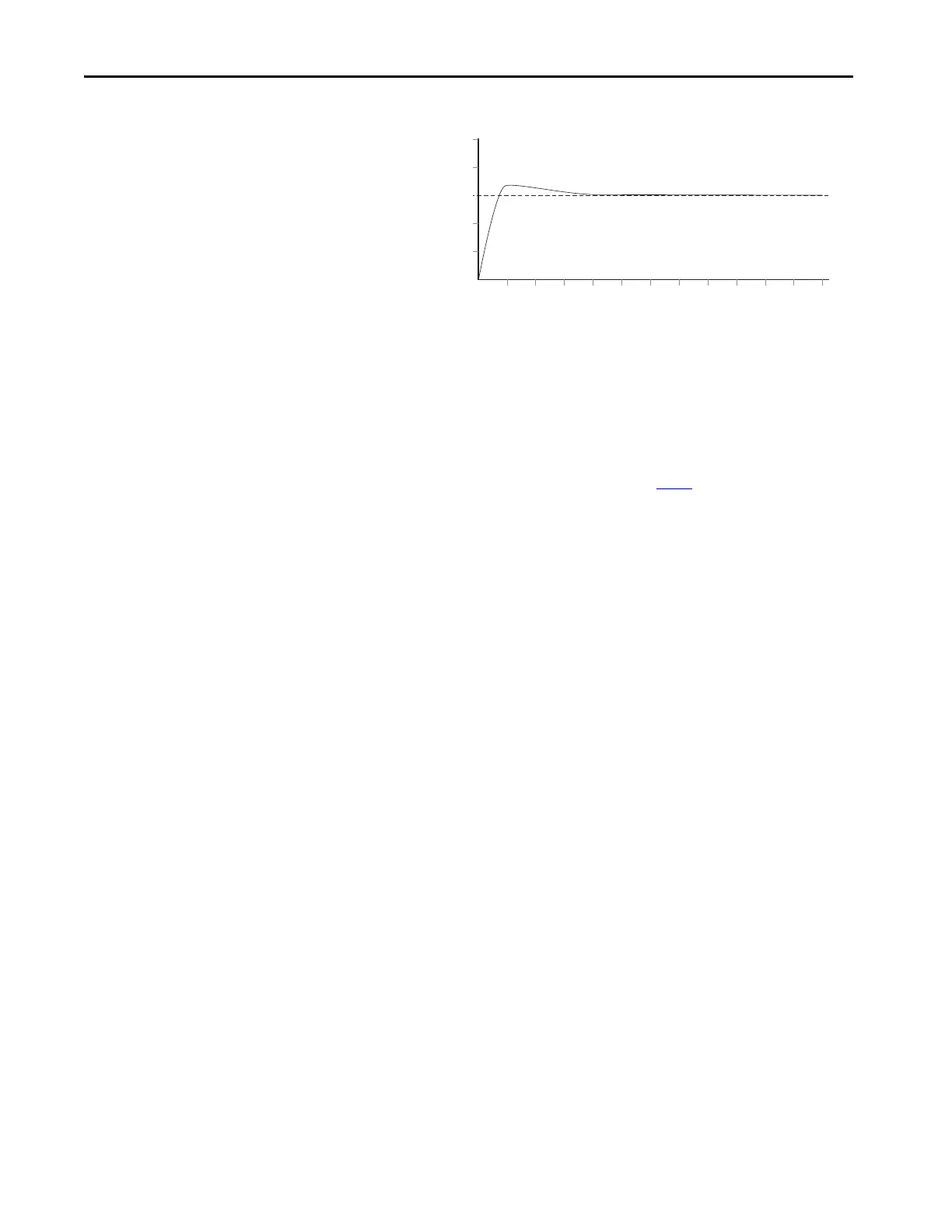

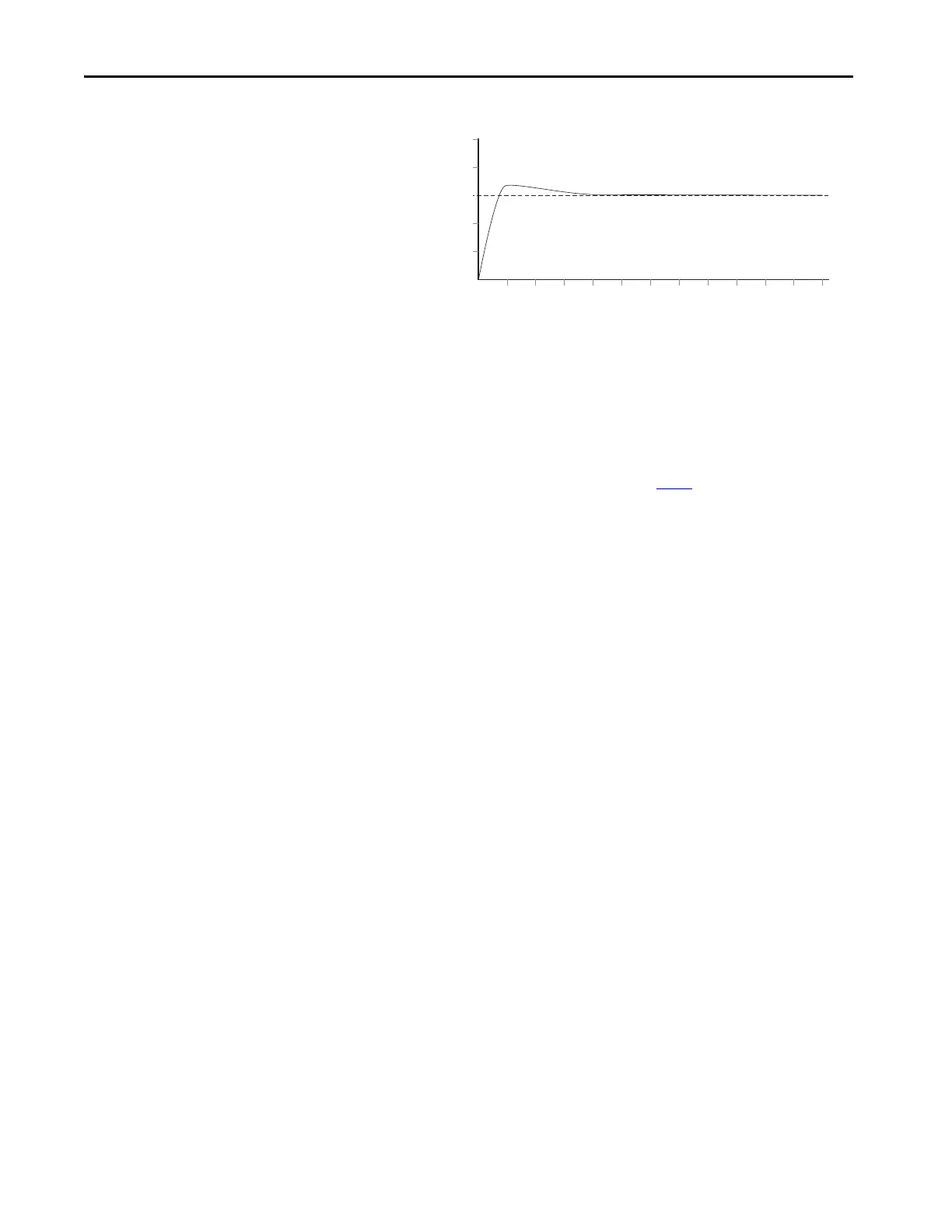

Figure 40 - Good Response – Critically Damped

Auxiliary Motor Control

Setup

The PowerFlex 400 has a built in Auxiliary Motor Control feature. This

feature allows operation of up to three (3) line-started motors in addition to

the motor controlled directly by the PowerFlex 400 drive. System output can

vary from 0% (auxiliary motors off and drive-controlled motor at zero speed)

to 400% (3 auxiliary motors and drive-controlled motor at full speed). To

enable the Auxiliary Motor Control, parameter R239

[Aux Motor Mode]

must be set to an option 1 “Enabled.” When enabled, the internal PID

controller in the PowerFlex 400 uses a reference and feedback signal to adjust

the speed of the drive controlled motor such that the feedback signal follows

the reference signal. When demand exceeds the first motors capacity, the

PowerFlex 400 Auxiliary Motor Control automatically starts an auxiliary

motor. The speed of the drive controlled motor is reduced to account for the

auxiliary motors additional output to the system. If demand continues to

increase, the PowerFlex Auxiliary Motor Control starts additional motors

using the same process. When demand decreases, an auxiliary motor is stopped

and the PowerFlex Auxiliary Motor Control increases the speed of the drive

controlled motor to account for lost system output. A Motor Interlock input

identifies motors that are out of service and causes them to skipped over to the

next available motor.

An AutoSwap function also can be used which allows equal wear to be placed

on each motor by periodically swapping the drive controlled and auxiliary

motors. Each motor in the system will over time be connected to the PowerFlex

400 drive and also directly to the AC line. During an AutoSwap, the motor

directly connected to the PowerFlex 400 drive is stopped and the contactor is

opened. The contactor of the next motor that will be controlled by the

PowerFlex 400 drive is opened if running across the AC line. A contactor is

closed connecting this motor directly to the PowerFlex 400 drive and is started.

An additional motor is line started if required.

PID Feedback

PID Reference

Time

Loading...

Loading...