86 Rockwell Automation Publication 2099-UM001D-EN-P - December 2012

Chapter 4 Connect the Kinetix 7000 Drive System

A good example of recommended cable is Belden/E 295xx (xx determines

gauge). This cable has four XLPE insulated conductors with a 100% coverage foil

and an 85% coverage copper braided shield (with drain wire) surrounded by a

PVC jacket.

Other types of shielded cable are available, but the selection of these types may

limit the allowable. Particularly, some of the newer cables twist four conductors

of THHN wire and wrap them tightly with a foil shield. This construction

increases the cable charging current required and reduces the overall drive

performance. Unless specified in the individual distance tables as tested with the

drive, these cables are not recommended and their performance against the lead

length limits supplied is not known.

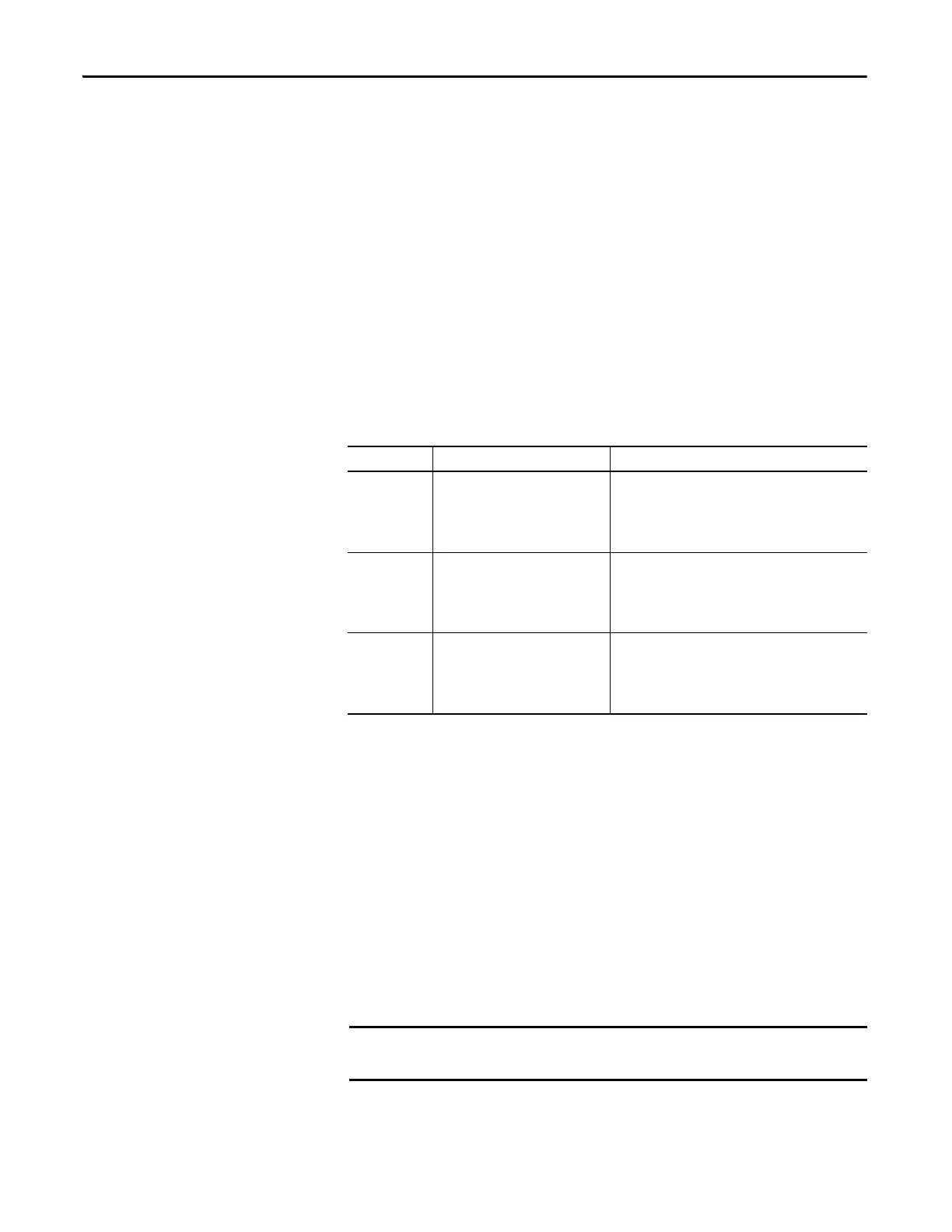

The table below describes the recommended shielded cables.

Table 33 - Shielded Cable Ratings and Types

Contactors

A contactor or other device that routinely disconnects and reapplies the AC line

to the drive to start and stop the motor can cause drive hardware damage. The

drive is designed to use control input signals that will start and stop the motor. If

an input device is used, operation must not exceed four cycles per minute

maximum, or damage will occur to the drive precharge circuit.

The start/stop/enable control circuitry for the drive includes solid state

components. If hazards due to accidental contact with moving machinery or

unintentional flow of liquid, gas or solids exist, an additional stop circuitry may

be required to remove the AC line to the drive. An auxiliary braking method also

may be required.

Location Rating/Type Description

Standard

(Option 1)

600V, 90 °C (194 °F),

XHHW2/RHW-2

Anixter B209500-B209507,

Belden B29501-B229507,

or equivalent

• Four tinned copper conductors with XLPE insulation

• Copper braid/aluminum foil combination shield and

tinned copper drain wire

• PVC jacket

Standard

(Option 2)

600V, 90 °C (194 °F),

RHH/RHW-2

Anixter OLF-7xxxxx,

or equivalent

• Three tinned copper conductors with XLPE insulation

• 5 mil single helical copper tape (25% overlap

minimum) with three bare copper grounds in contact

with shield

• PVC jacket

Class I & II;

Division 1 & II

Tray rated 600V, 90 ° C (194 ° F),

XHHW2/RHW-2

Anixter 7V-7xxxxx-3g,

or equivalent

• Three bare copper conductors with XLPE insulation

and impervious corrugated continuously welded

aluminum armor

• Black sunlight resistant PVC jacket overall

• Three copper grounds on 5 mm

2

(10 AWG) and smaller

It is recommended that the drive safe-off function be used to minimize

contactor cycling.

Loading...

Loading...