30 Rockwell Automation Publication 2080-UM005B-EN-E - March 2015

Chapter 4 Wire Your Controller

• Separate wiring by signal type. Bundle wiring with similar electrical

characteristics together.

• Separate input wiring from output wiring.

• Label wiring to all devices in the system. Use tape, shrink-tubing, or other

dependable means for labeling purposes. In addition to labeling, use

colored insulation to identify wiring based on signal characteristics. For

example, you may use blue for DC wiring and red for AC wiring.

Wire Requirements

Use Surge Suppressors

Because of the potentially high current surges that occur when switching

inductive load devices, such as motor starters and solenoids, the use of some type

of surge suppression to protect and extend the operating life of the controllers

output contacts is required. Switching inductive loads without surge suppression

can significantly reduce the life expectancy of relay contacts. By adding a

suppression device directly across the coil of an inductive device, you prolong the

life of the output or relay contacts. You also reduce the effects of voltage

transients and electrical noise from radiating into adjacent systems.

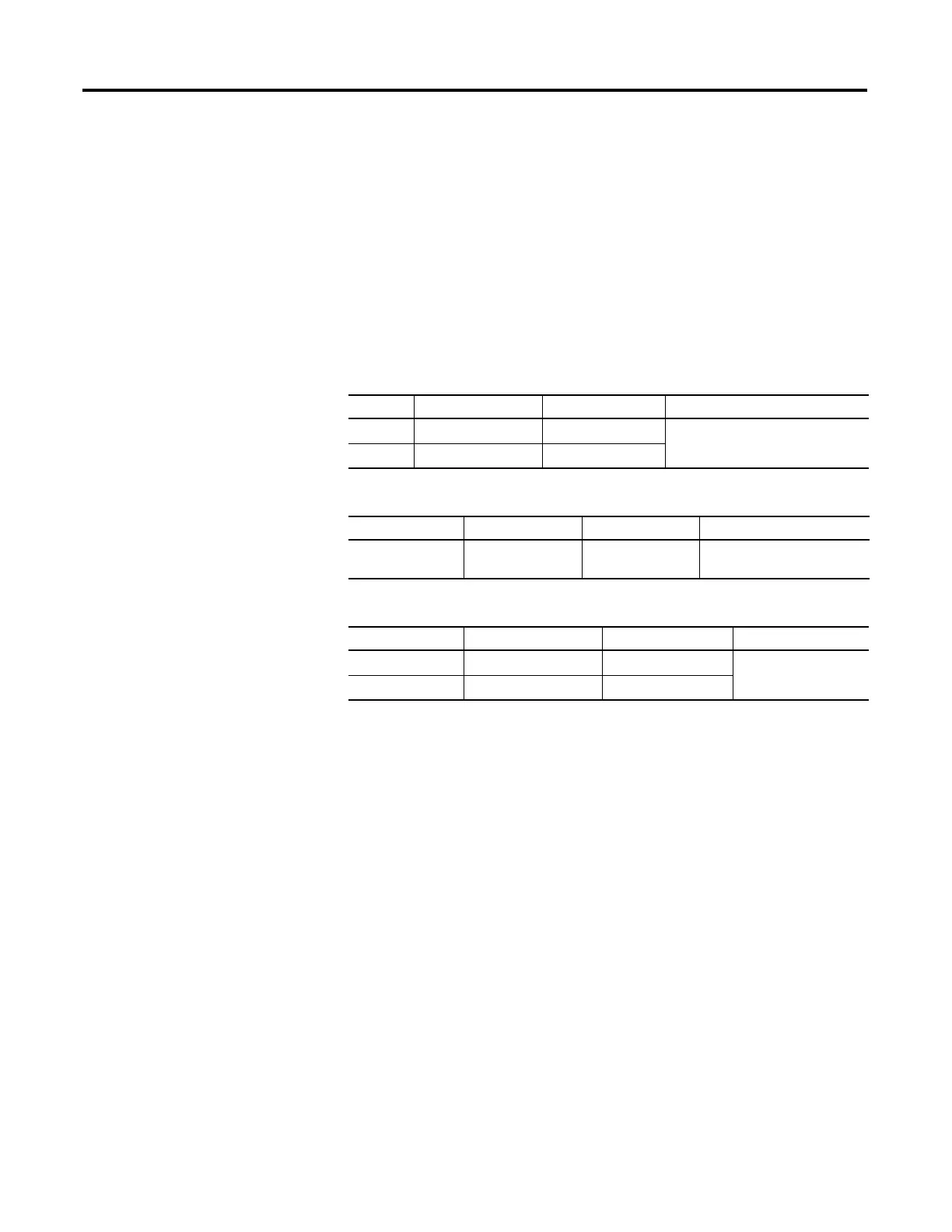

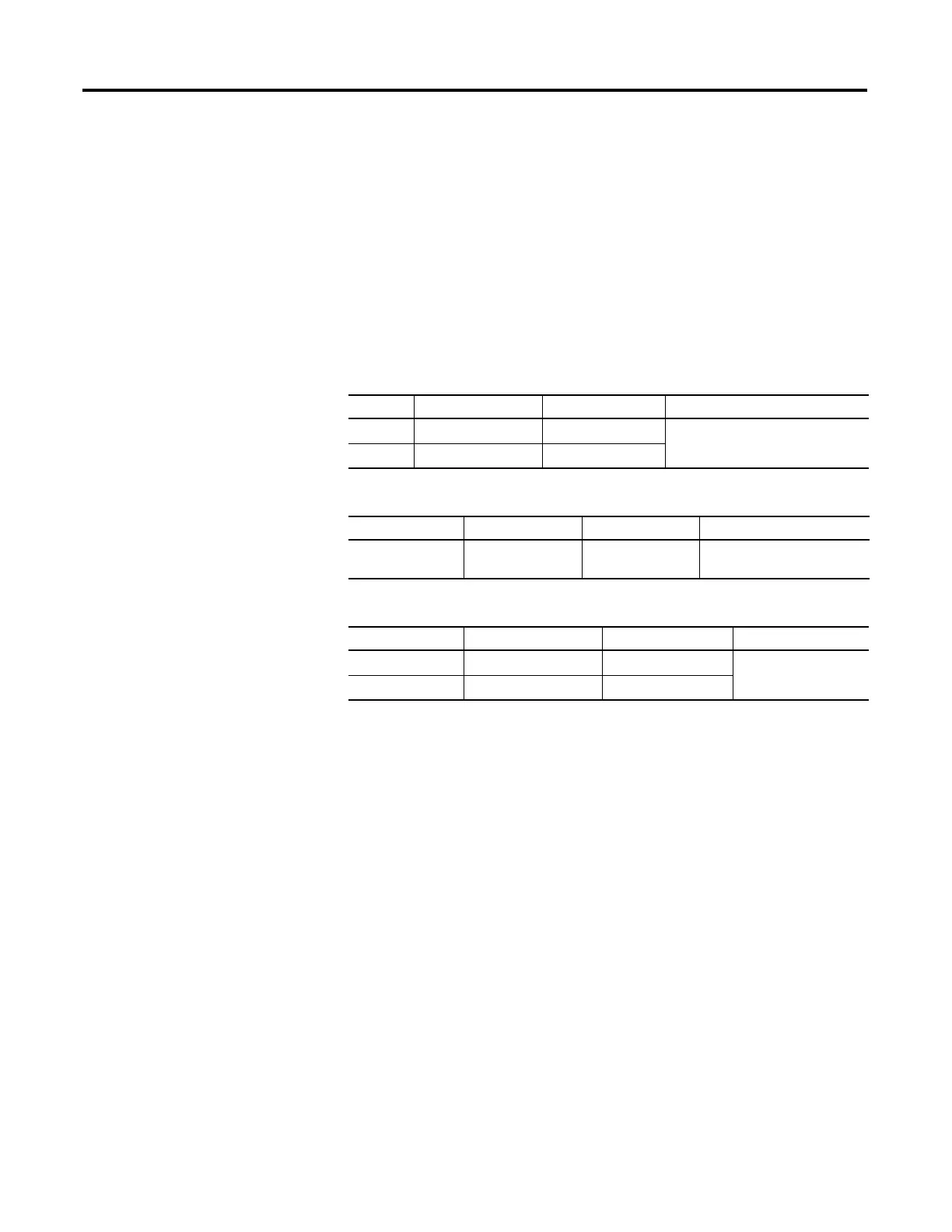

Wire Requirements for fixed terminal blocks

Min Max

Solid 0.14 mm

2

(26 AWG) 2.5 mm

2

(14 AWG) rated @ 90 °C (194 °F ) insulation

max

Stranded 0.14 mm

2

(26 AWG) 1.5 mm

2

(16 AWG)

Wire requirements for removable terminal blocks

Min Max

Solid and Stranded 0.2 mm

2

(24 AWG) 2.5 mm

2

(14 AWG) rated @ 90 °C (194 °F )

insulation max

Wire requirements for RS232/RS485 serial port terminal block

Min Max

Solid 0.14 mm

2

(26 AWG) 1.5 mm

2

(16 AWG) rated @ 90 °C (194 °F)

insulation max

Stranded 0.14 mm

2

(26 AWG) 1.0 mm

2

(18 AWG)

Loading...

Loading...