Azbil Corporation Installation

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-43

2.6 : Installing a Union / Hose / Clamp Detector

2.6.1: Installation of Union and Hose assemblies basic

installation method

Direction of installation

Match the ow direction of the uid to be measured to that of the ow direction

mark on the electromagnetic owmeter. If they cannot be matched, the direction can

be changed on the terminal box or the converter. Refer to the section “Direction of

terminal box / converter”.

Position of the detector

Position the detector so that the center of the pipe aligns with that of the measuring

pipe of the electromagnetic owmeter. Be sure to fasten the electromagnetic

owmeter on a stand.

Pipe connection

For union assembly, mount the union joint nuts (supplied by the customer) on

the process pipe. Connect the pipe by screwing it into the connection hole of the

electromagnetic owmeter using the union joint nuts. For hose assembly, screw in the

hose, and fasten it with a fastening band, etc. (supplied by the customer).

Nut tightening (union assembly)

Use a torque wrench to tighten the union joint nuts. Do not tighten them fully to the

specied fastening torque one at a time. Instead, tighten the upstream and downstream

joint nuts alternately little by little over three or four turns. For the fastening torque,

see Table 2-9.

CAUTION

Fasten the detector using the specied fastening torque to prevent leakage.

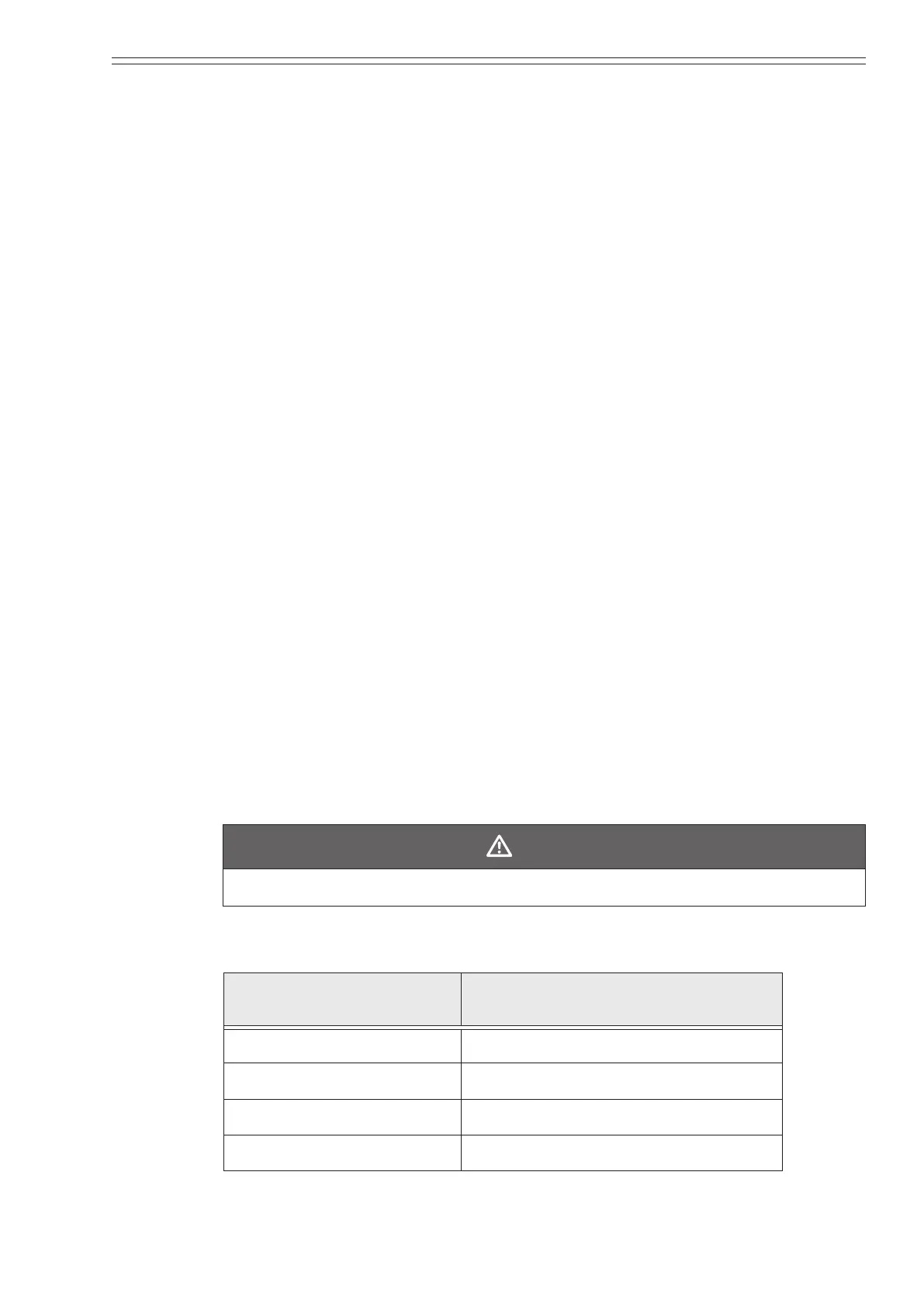

Table 2-9 Fastening torque

Nominal detector bore

mm (inch)

Fastening torque

N•m (ft•lb)

2.5 (0.1) Max. 12 (8.9)

5 (0.2) Max. 12 (8.9)

10 (3/8) Max. 18 (13.3)

15 (1/2) Max. 18 (13.3)

Loading...

Loading...