SB-170-10 55

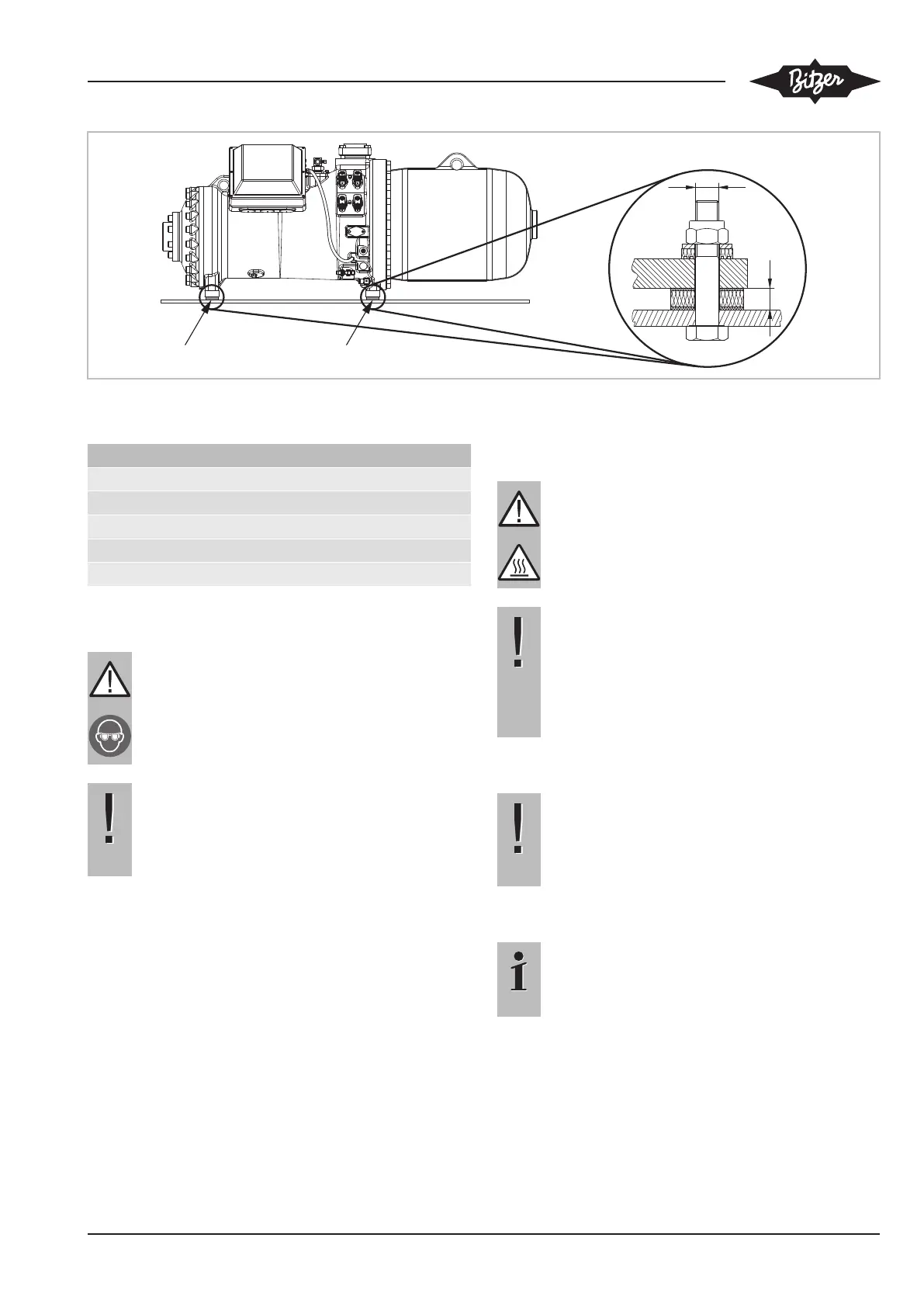

Fig.4: Mounted vibration dampers

Only with the models CS.9.53 to CS.9.73 different vibration dampers are used for position 1 and 2: 1 = blue and 2 = yellow.

Compressor series M

CS.6. M10

CS.7. M16

CS.8. M16

CS.9. M20

CS.105 M20

5.3 Connecting the pipelines

WARNING

The compressor is under pressure!

Serious injuries are possible.

Depressurize the compressor!

Wear safety goggles!

NOTICE

Potential chemical reactions due to air penetra-

tion!

Proceed swiftly and keep shut-off valves closed

until evacuation.

5.3.1 Pipe connections

The pipe connections are suitable for pipes in all com-

mon dimensions in millimetres and inches. Brazed con-

nections have stepped diameters. The pipe will im-

merge more or less depending on its dimensions. If ne-

cessary, the bushing may even be cut at the end with

the largest diameter.

5.3.2 Shut-off valves

CAUTION

Depending on the operation mode, the shut-off

valves may become very cold or very hot.

Risk of burning or frostbite!

Wear suitable protective equipment!

NOTICE

Do not overheat the shut-off valves!

Cool the valve body and the brazing adapter

during and after the brazing operation.

Maximum brazing temperature 700°C!

For welding, dismount the pipe connections and

the bushes.

When turning or mounting shut-off valves:

NOTICE

Risk of damage to the compressor.

Tighten screws crosswise in at least 2 steps to

the prescribed tightening torque.

Test tightness before commissioning!

When retrofitting the ECO shut-off valve:

Information

To increase the corrosion protection, it is recom-

mended to coat the surface of the ECO shut-off

valve.

Loading...

Loading...