21

F

Drilling of hinge pattern

!

F11

F12

F13

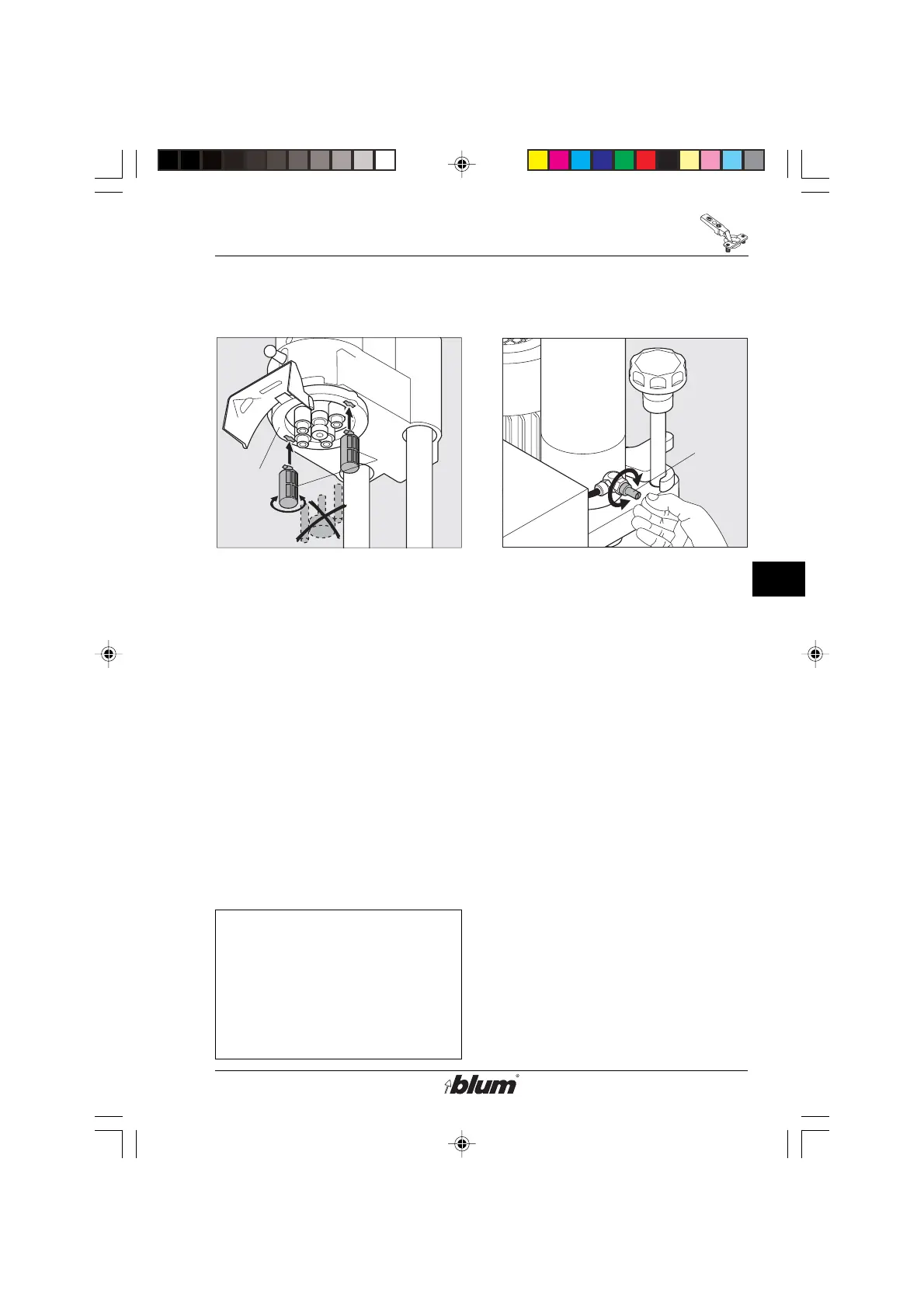

7. Drilling depth stop (F11)

Alternatively, drilling depth stops can be

mounted to ensure a constant drilling

depth. If these stops are mounted, the

drilling depth will always be 1/2“ (12.7

mm), regardless of the thickness of

the workpiece.

Mounting the drilling depth stops:

• Before mounting the depth stops,

disconnect the machine from it’s

electrical source (unplugged).

• Main switch to setup position.

• Remove the drill bit.

• Push the drilling depth stops into the

keyholes of the retaining ring (F12)

until they won’t go any further and

turn them by 90°.

Important:

The drill bit length must be

set to 2-1/4“ (57 mm) (see

section F, item 2). The drilling

depth adjuster (F10) bolt must

not stop before the drilling

depth is reached (turn it back

by a sufficient amount).

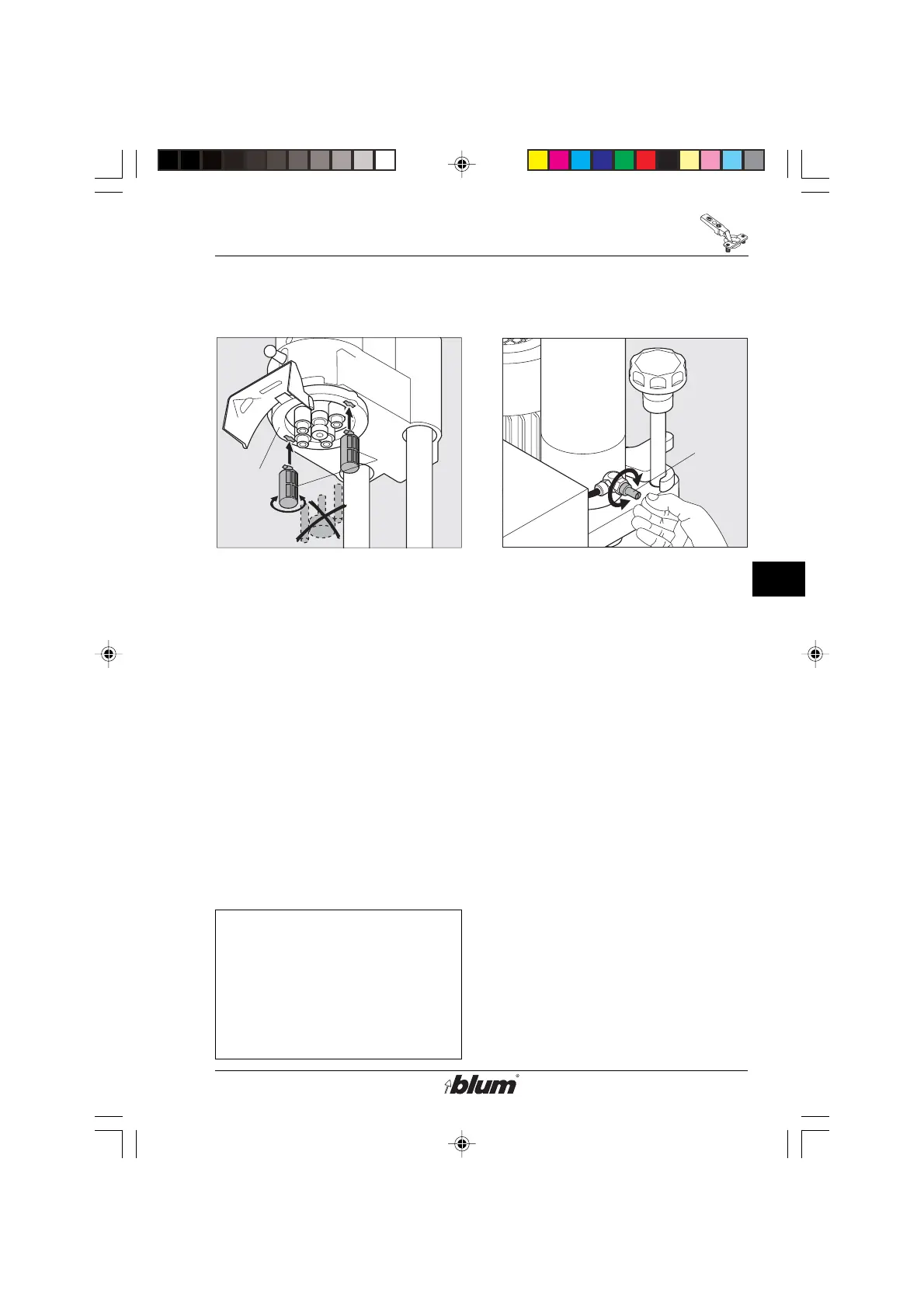

8. Adjusting the stroke speed

Adjustment of the stroke speed is made

by means of the knurled screw (F13) at

the back of the cylinder.

• faster: turn screw (F13)

counter-clockwise

• slower: turn screw (F13)

clockwise

%$0,1,35(66)$,G1US $0

Loading...

Loading...