12

Automatic Test

The AUTOMATIC TEST sub m enu is used to ex ecute all the

app licable tests to t h e system au tom atically. Th ese in clu d e

independent component, cooling, heating, and a system one.

Table 5 shows the steps taken during the independent, cooling,

and heatin g auto m atic tests. T h e Ho l d tim e rep resen ts th e time at

which that control waits before moving on to the next step.

The AUTO SYSTEM TEST will execute the independent auto

test, then the cooling auto test, then the heating auto test. At the end

of the system auto test a prompt will ask if you want to enter

measured data and complete a service report.

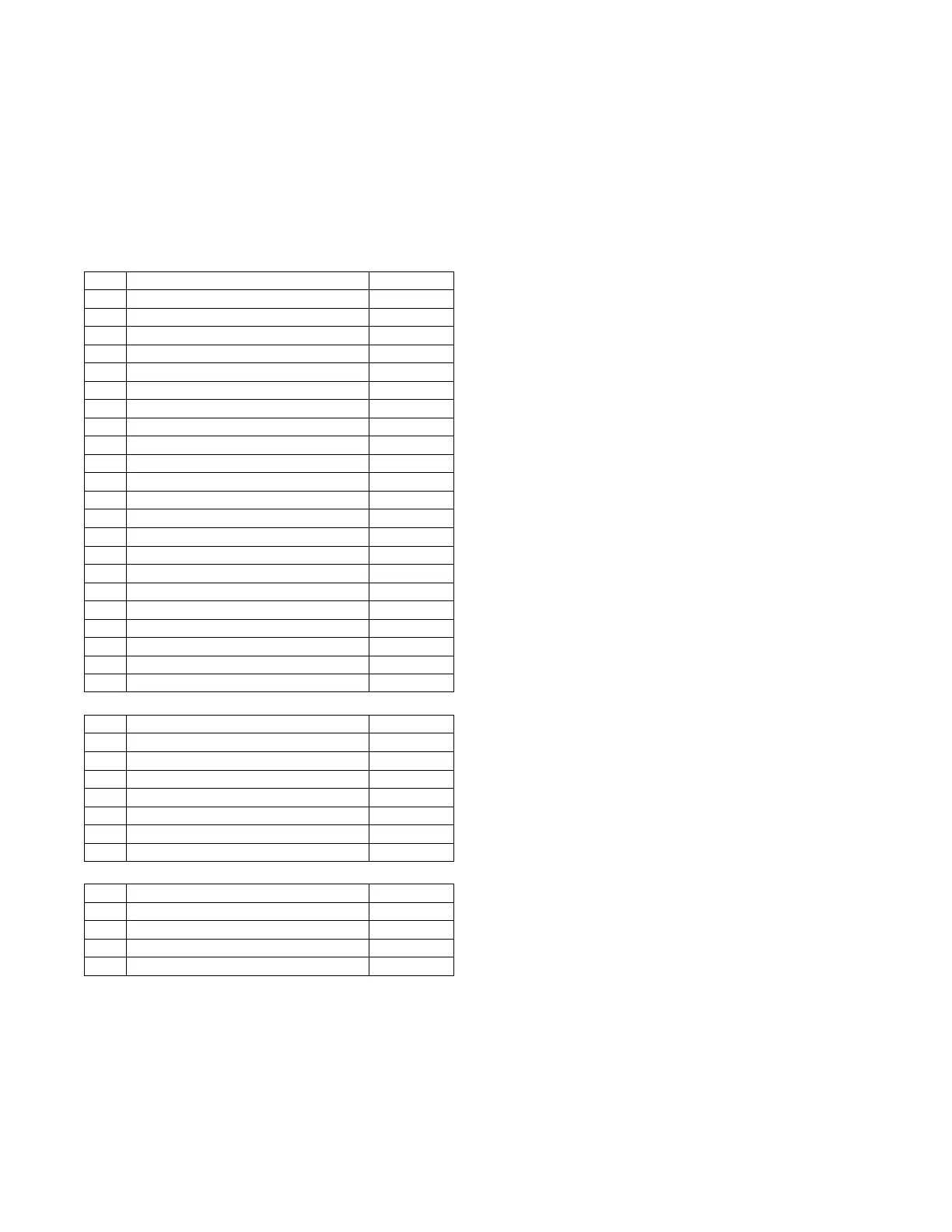

Table 5 – Independent, Cooling, and Heating Automatic Tests

AUTO INDP TEST

Step Action Hold (Sec)

1 Turn on Crankcase Heater Relay 0

2 Set ODF1 to the High Cool Speed 30

3 Set ODF1 to the Minimum Speed 30

4 Tur n ODF1 of f 5

5 Set ODF2 to the High Cool Speed 30

6 Set ODF2 to the Minimum Speed 30

7 Tur n OD21 of f 5

8 Set ODF3 to the High Cool Speed 30

9 Set ODF3 to the Minimum Speed 30

10 Tu rn OD F3 off 5

11 Se t IDF speed to 100% 30

12 Se t Economizer Dam per to 100% 60

13 Tu rn o n power e xhaust 1 10

14 Tu rn o n power e xhaust 2 10

15 SetEconomizerDamperto0% 60

16 Tu r n off power exhaust 2 10

17 Tu r n off power exhaust 1 10

18 Set IDF to the ventilation speed 30

19 Turn on al arm relay 10

20 Turn off alarm relay 10

21 Set IDF to 0% speed 30

22 Turn off Crankcase Heater relay 0

AUTO COOL TEST

Step Action Hold (Sec)

1 Set ODF auto transition 0

2 Set IDF auto transition 0

3 Turn on Cool A1 test 60

4 Turn off Cool A1 test 30

5 Turn on Cool A2 test 60

6 Turn on Cool A1 and Cool A2 tests 30

7 Turn off Cool A1 and Cool A2 tests 60

AUTO HEAT TEST

Step Action Hold (Sec)

1 Set IDF auto transition 0

2 Tur n on He at 1 te st 60

3 Tur n on He at 2 te st 60

4 TurnoffHeat1andHeat2tests 20

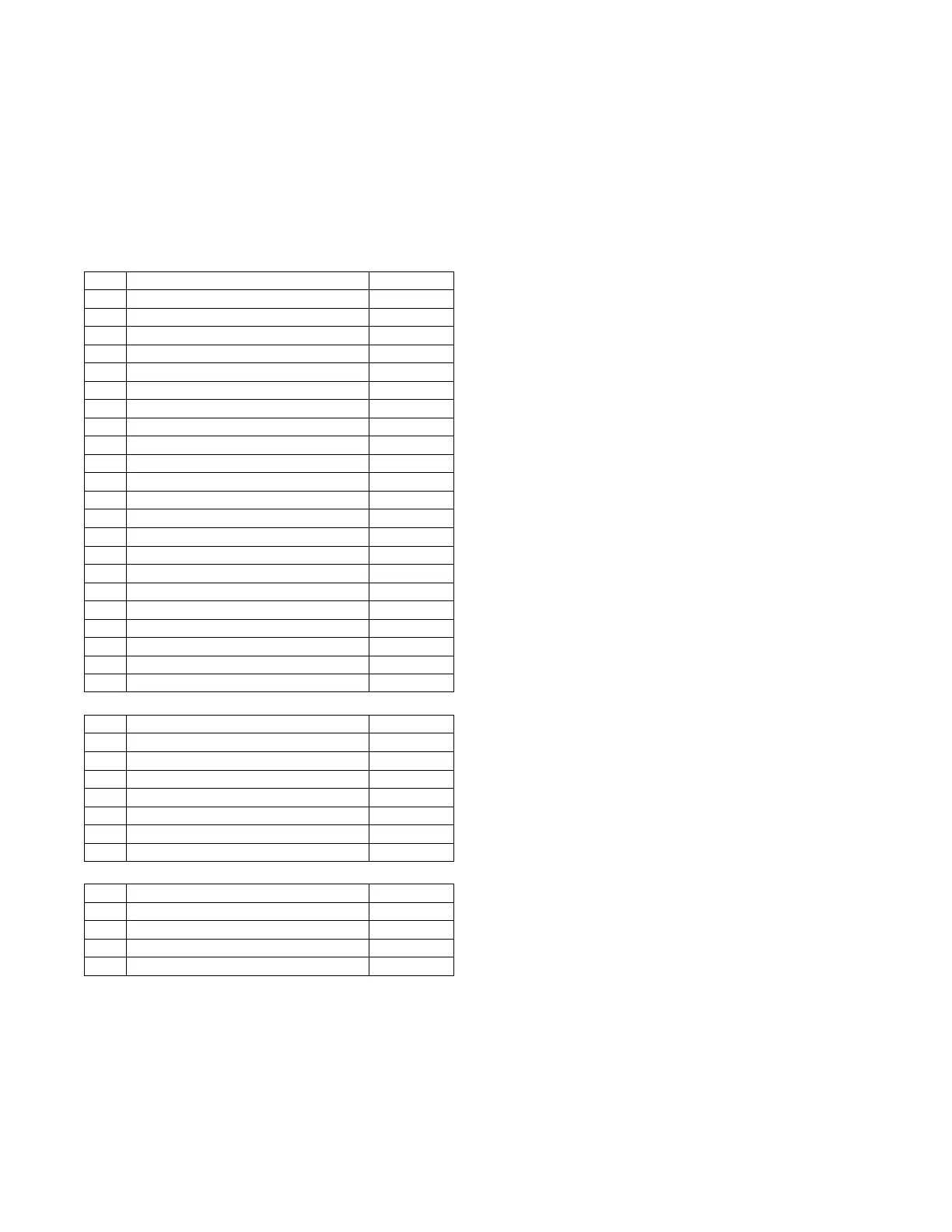

THIRD PARTY CONTROL

Third party controls may interface with the unit SystemVut

controller through the connections described below. See other

sections of these instructions for more information on the related

unit control and configurations.

Cooling/Heating Control

The thermostat inputs are provided on TB1 of the board. The

Unit Control Type configuration, UNIT CONTROL TYPE,

must be 0 (Tstat) to recognize the below inputs. Terminal R is

the 24 -- VAC source for the following:

Y1 = first stage cooling

Y2 = second stage cooling

Y3 = third stage cooling

W1 = first stage heating

W2 = second stage heating

G = Indoor fan

Dehumidification Control

On Humidi--MiZer

R

system units the HUMIDIST AT and SPRH leads

are provi ded with quick connects. The Space Humidi ty Switch

configuration, SETTINGSUNIT CONFIGURATIONS

SWITCH INPUTS CONFIGSHUMSTA T CHANNEL

identifi es the norm ally open or normally closed sta tus of this input at

HIG H humidity. The RH Sensor conf i gurati on, SETTINGS UNIT

CONFIGURATIONSANALOG INPUTS CONFIGS SPRH

SENSOR CHANNEL, ident ifies the point on t he MBB (Main Bas e

board) or t he IOB (Input Output board) the sensor was wir ed into.

Remote Occupancy

The remote occupancy input can be provided on one of the

configurab le inputs, most commonly TB3. The Remote

Occupancy Switch configuration, REMOTE OCC TYPE,

identifies the normally open or normally closed status of this input

when unoccupied. The Remote Occupancy Channel configuration,

REMOTE OCC CHAN, identifies the discrete input (DI) assigned

for this function.

Remote Shutdown

The re m ote shut dow n input is pr ovi ded for unit shutdown in re sponse

to swi t ch input configured most com monly on TB3. The Remote

Shutdown Switch c onfiguration, REM. SHUTDOWN TYPE,

identifi es the norm ally ope n or nor mally closed status of this i nput

whe n there is no shutdow n command. The Remot e Shutdown

Channel c onf iguration, REM. SHUTDOWN CHAN, identifies the

discrete input (DI) assigned for t hi s function.

Alarm Output

The alarm output is provided on as a configurable relay, most

commonly on TB2, to indicate when a current alarm is active. The

output will be 24-- VAC if a current alarm exists. The Alarm Relay

Channel configuration, ALM RELY CHANNEL, identifies the

discrete output (DO) assigned for this function.

Economizer Damper Control

For units with the economizer option or accessory, the damper

position can be directly controlled through the IAQ sensor input.

The IAQ Analog Input configuration, IAQ LEVEL CONTROL

will have to set to 2 (CTL MINP). When IA.CF = 2, an external 4

to 20 mA source is used to move the damper 0% to 100% directly.

CONTROLS OPERATION

Display Configuration

The SETTINGSDISPLAY S ETTINGS submenu is used to

configure the local display settings.

METRIC DISPLAY

This variable is used to change the display from English units to

Metric units.

LANGUAGE

This variable is used to change the language of the SystemVu

display. At this time, only English is available.

CONTRAST ADJUST

This is used to adjust the contrast of the SystemVu display.

Loading...

Loading...