37

Cooling Troubleshooting

Use the SystemVut Display or a CCN device to view the cooling

status display and the cooling diagnostic display (see Appendices)

for information on the cooling operation. Check the current alarms

and alarm history for any cooling alarm codes and correct any

causes. (See Table 13.) Verify any unique control configurations

per installed site requirements or accessories.

If alarms conditions are corrected and cleared, operation of the

compressors and fans may be verified by using the Service Test

mode. (See Table 4.) See Table 15 for general cooling service

analysis.

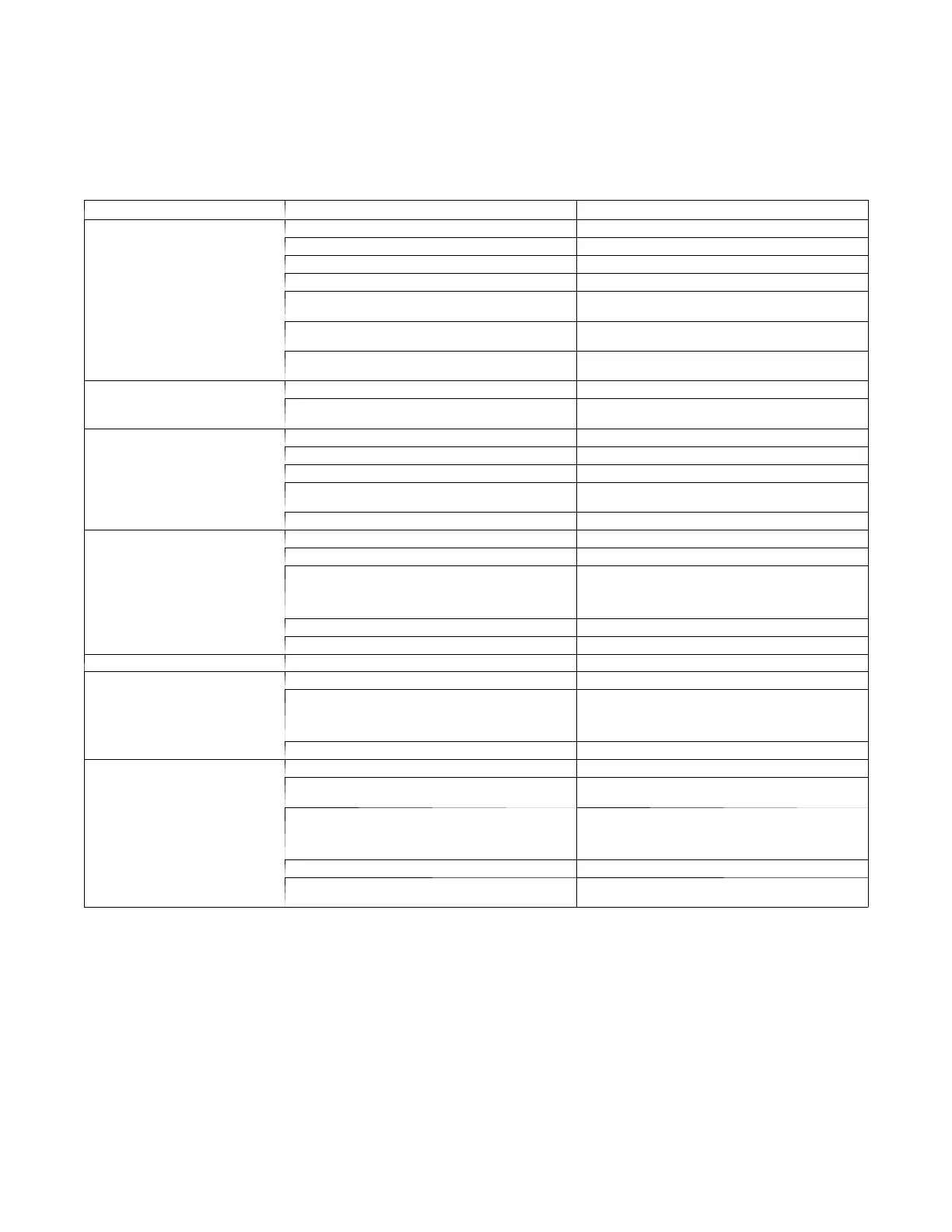

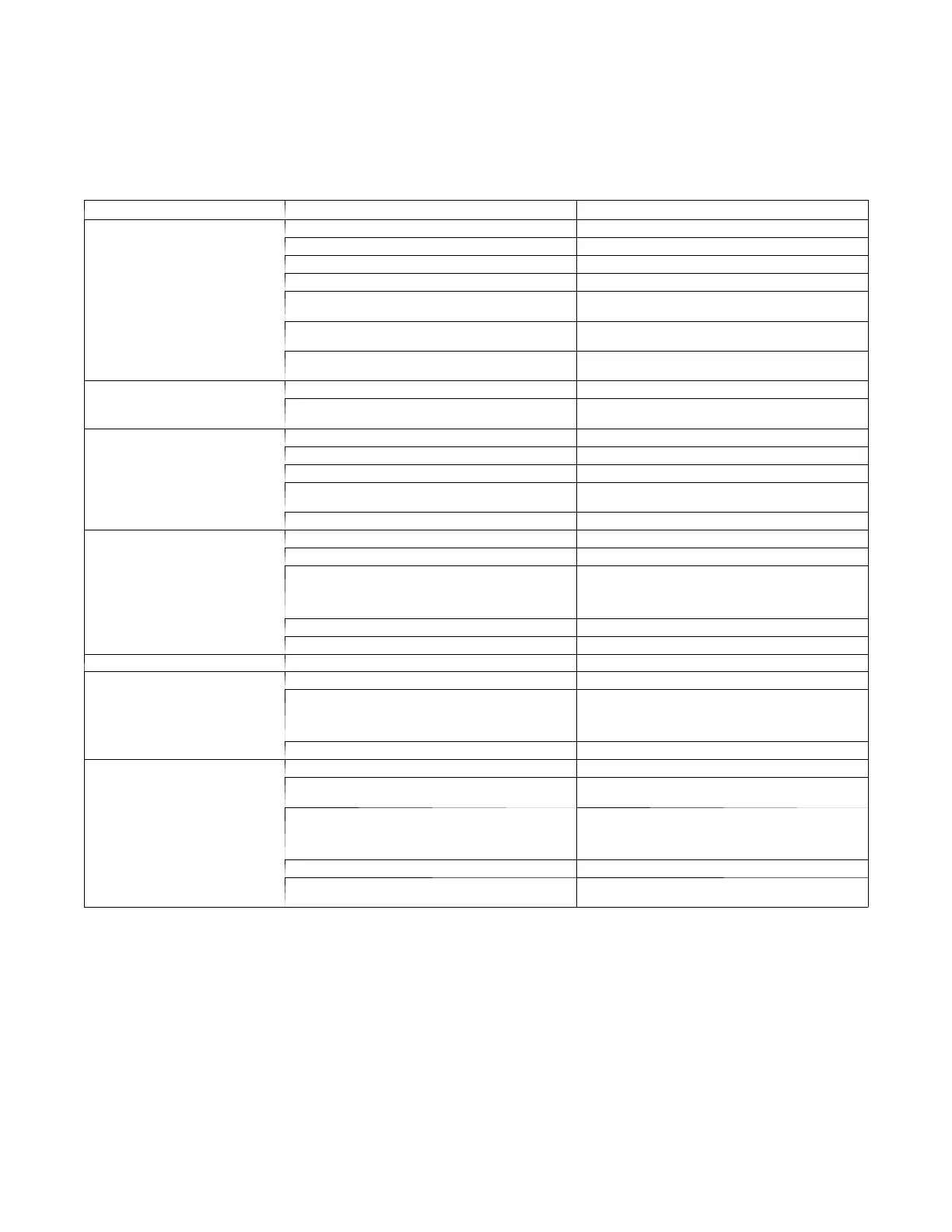

Table 15 – Cooling Service Analysis

PROBLEM CAUSE REMEDY

Compressor and Fan Will Not

Start.

Power failure. Call power company.

Fuse blown or circuit breaker tripped. Replace fuse or reset circuit breaker.

Disconnect off. Power disconnect.

Compressor time guard to prevent short cycling. Check using SystemVu Display .

Thermostat or occupancy schedule set point not

calling for Cooling.

Check using SystemVu Display.

Outdoor temperature too low. Check Compressor Lockout Temperature using

SystemVu Display.

Active alarm. Check active alarms using SystemVu Scrolling

Marquee.

CompressorCycles(otherthan

normally satisfying thermostat).

Insufficient line voltage. Determine cause and correct.

Active alarm. Check active alarms using SystemVu Scrolling

Marquee.

Compressor Operates

Continuously.

Unit undersized for load. Decrease load or increase size of unit.

Thermostat or occupancy schedule set point too low. Resetthermostatorschedulesetpoint.

Dirty air filters. Replace filters.

Low refrigerant charge. Check pressure, locate leak, repair, evacuate, an d

recharge.

Condenser coil dirty or restricted. Clean coil or remove restriction.

Excessive Condenser Pressure s.

Dirty condenser coil. Clean coil.

Refrigerant overcharge. R ecover excess refrigerant.

Faulty TXV . 1. Check TXV bulb mounting and secure tightly to

suction line and insulate.

2. Replace TXV (and filter drier) if stuck open or

closed.

Condenser air restricted or air short cycling. Determine cause and correct.

Restrictioninliquidtube. Remove restriction.

Condenser Fans Not Operating. No Power to contactors. Fuse blown or plug at motor loose.

Excessive Suction Pressure.

High heat load. Check for sources and eliminate

Faulty TXV . 1. Check TXV bulb mounting and secure tightly to

suction line and insulate.

2. Replace TXV (and filter drier) if stuck open or

closed.

Refrigerant overcharged. Recover excess refrigerant.

Suction Pressure Too Low.

Dirty air filters. Replace air filters.

Low refrigerant charge. Check pressure, locate leak, repair, evacuate, an d

recharge.

Faulty TXV . 1. Check TXV bulb mounting and secure tightly to

suction line and insulate.

2. Replace TXV (and filter drier) if stuck open or

closed.

Insufficient evaporator airflow. Check belt tension. Check for other restrictions.

Temperature too low in conditioned area (low

return-air temperature).

Reset thermostat or occupancy schedule.

LEGEND

TXV --- Thermostatic Expansion Valve

Loading...

Loading...