13

PASSWORD ENABLE?

This va riabl e enables or disables the us e of a use r password. The

passwor d is us ed to re stric t use of the control to c hange conf igurations.

VIEW USER PASSWORD

This menu allows the user to view the user password. The

password must be entered or disabled to view it.

CHANGE USER PASSWORD

This menu allows the user to change the user password. The

password must be entered or disabled to change it.

Unit Configuration

Many configurations that indicate what factory options and/or field

accessories are installed and other common operation variables are

included in SETTINGSUNIT CONFIGURATION submenu.

Some of these configurations will be set in the factory for the

factory--installed options (FIOPs). Field installed accessories and

custom control functions will require configuration changes. The

SETTINGSUNIT C ONFIGURATIONGENERAL submenu

contains the following control configurations. Refer to other

specific sections for other configurations.

STARTUP DELAY

This configuration sets the control start-up delay after the power is

interrupted. This can be used to stagger the start-up of multiple

units.

UNIT CONTROL TYPE

This configuration defines if temperature control is based on

thermostat inputs or space temperature sensor input. TSTAT value

is when then unit determines cooling and heating demand by the

state of G, Y1, Y2, W1, and W2 inputs from a space thermostat.

This value is the factory default. SPACE SEN value is when the

unit determines cooling and heating demand based on the space

temperature and the appropriate set point. RAT SEN value is when

the unit determines cooling and heating demand based on the

return air temperature and the appropriate set point. SPACE SEN

or RAT SEN are also used as Linkage configuration.

THERMOSTAT TYPE

This configuration applies only if Unit Control Type is Thermostat.

The value determines how the inputs are interpreted. See the

specific operation sections for more information. The following

descriptions define what each value means.

0 = CONV 2C2H – Conventional Thermostat 2 stage cool and

2 stage heat.

1 = DI GI 2C2H – Digital Thermostat 2 st age cool and 2 stage heat.

2 = CONV 3C2H – Conventional Thermostat 3 stage cool and

2 stage heat. This is the default setting.

3 = DIGI 3C2H – Digital Thermostat 3 stage cool and 2 stage heat.

ADAPTIVE TSTAT

This configuration applies only if the Unit control type is

Thermostat. When this is YES the control will use Adaptive

Control for cooling and heating staging. When this is set to NO the

control will use the Traditional Thermostat Control, however

during integrated cooling Adaptive is always used.

DIRTY FILTER TIME

This configuration defines the life of the installed filter. A timer

will count down from this number while the indoor fan is running.

At the expiration of this timer, an alert will be activated to indicate

a filter change is required.

TEST MODE TIMEOUT

This configuration defines the time at which a test mode test has

not changed state will automatically disable test mode. This

configuration will disable the timeout when set to 0 (Disabled).

CCH MAX TEMP

This configuration defines the temperature threshold for which the

crankcase heater is no longer required to heat the compressor shell.

STD BARO PRESSURE

This configuration is used to spe cify the job location’s st andar d

barometer pressure reading. This will feed the BAROMETRIC

PRESS when a network is not writing to it. This should be used to

account for job si te ele vation if e nthalpy calculations are bei ng use d.

LINK STAGEUP TIME

This configuration sets the cooling and heating stage up time

during linkage operation.

Configurable Switches and Analog sensors

The Syst emV ut cont roller has opti onal conf i gurable inputs . These

consist of five physi cal boar d switch input s (di screte input s) a nd three

physical board analog input s. There are more functions all ow ed for

configuration than the re are inputs. Eac h func tion will have a

configuration for which input cha nnel it is as signed to. Each switch

function wil l al so have a switch type configuration whi ch defines tha t

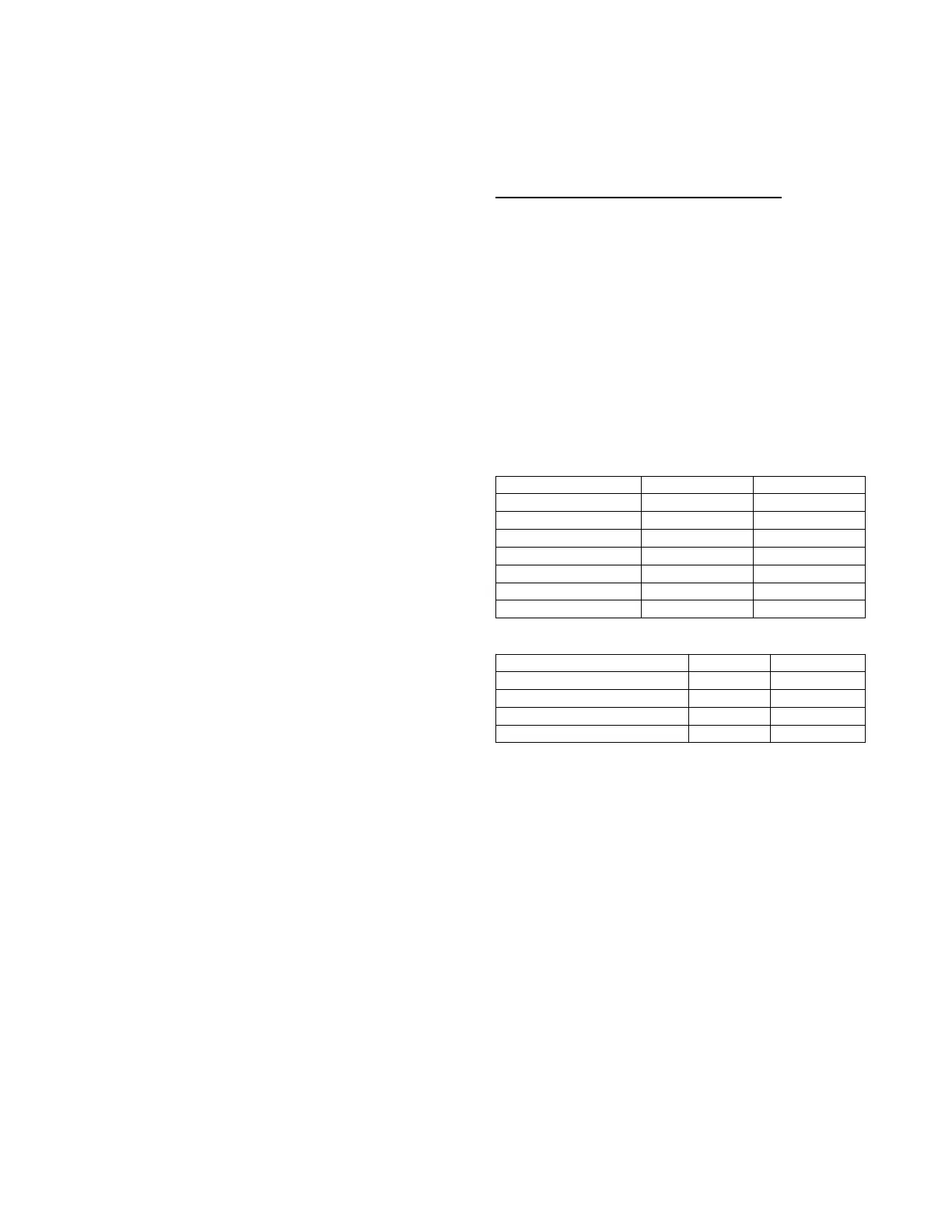

sw i tches norma l st ate. Ta ble 6 shows the conf igurabl e functions and

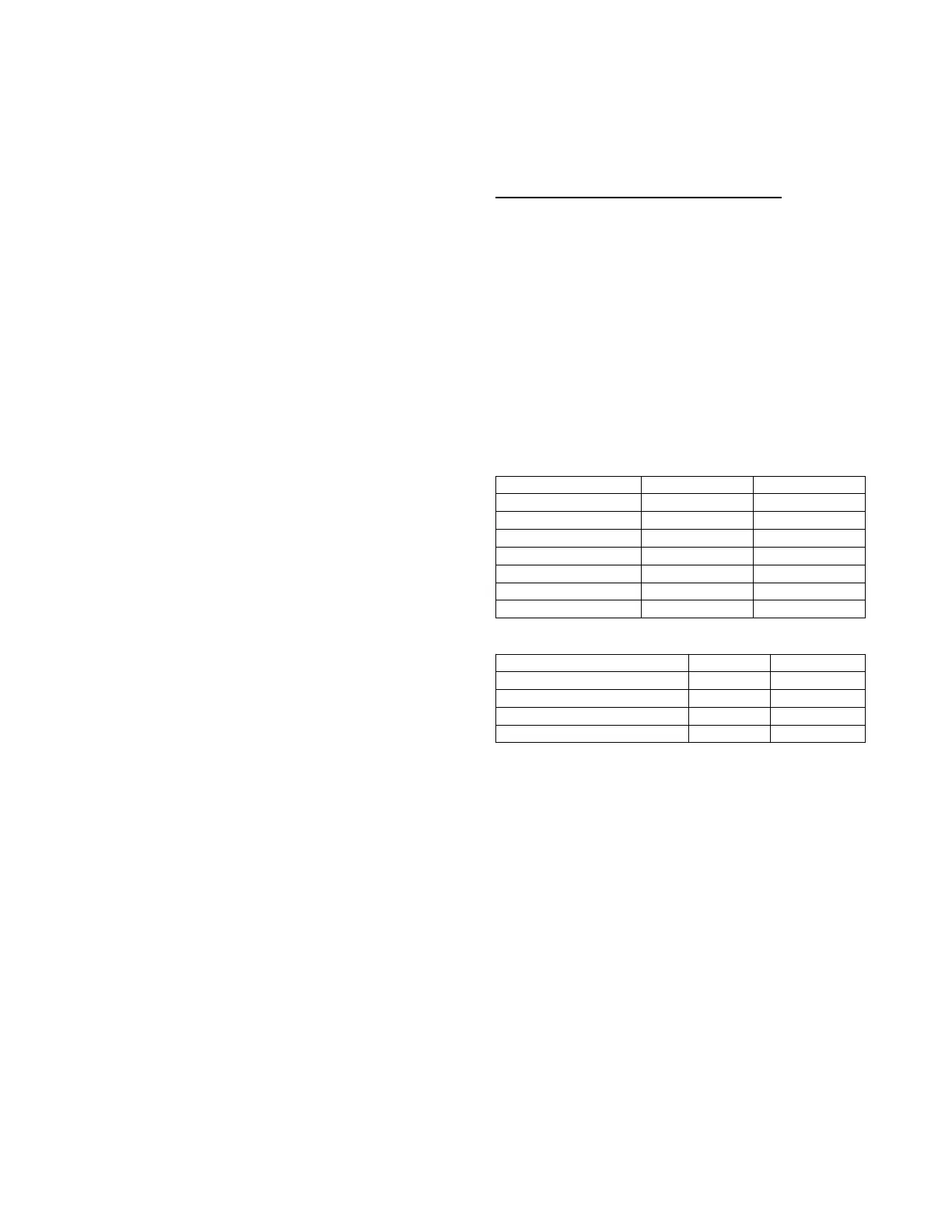

wha t the ir normal and ac tive states a re. Tabl e 7 shows the configurable

analog input func t ions. The switch conf igurations ca n be found in the

SETTINGSUNIT CONFIGURATIONSSWITCH INPUT

CONFIGS sub--menu. The analog input configurations ca n be found

in the SETTINGUNIT CONFIGURATIONSSWITCH INPUT

CONFIGS sub--menu. The configurabl e input as signment can be

viewed in the SER VI CEHARDWAREASSIGNED

INPUTS/ OUTPUTS sub--menu.

Table 6 – Configurable Switch Input Functions

F unction Description Normal State Active State

Humidistat OFF ON

Condensate Overflow LOW HIGH

Filter Status Switch CLEAN DIRTY

Remote Occupancy UNO CC OCCUP IED

Remote Shutdown RUN SHUTDOWN

General Status Switch GOOD ALARM

Enthalpy Switch Input LOW HIGH

Table 7 – Configura ble Analog Input Functions

F unction Description Sensor Type Sensor Values

Space Air Relative Humidity Sensor 0 --- 2 0mA %RH

Return Air Relative Humidity Sensor 0 --- 2 0 mA %RH

Indoor Air CO

2

Sensor 0 --- 2 0mA PPM

Outside Air CO

2

Sensor 0 --- 2 0m A CFM

General Operation

48/50LC units can provide cooling, dehumidification, heating, and

ventilation. The operating mode (MODE) shows the highest level

of operation of the unit at any given time. The operating sub--mode

(SUB-- MODE) shows the detail operation occurring while under a

specific mode. Fig. 10 shows the MODE and SUB -- MODE values.

Each unit will operate under one of three basic types of control,

thermostat, space temperature sensor, or return air temperature

sensor. There are many inputs, configurations, safety factors, and

conditions that ultimately control the unit. Refer to the specific

operation sections for detail on a specific unit operation. The

control will set the demand based on these types of control and

conditions, which then drives the operating mode.

When thermostat control is enabled (UNIT CONTROL TYPE),

the unit will operate based on discrete input commands (G, Y1,

Y2, Y3, W1, and W2) and there is a one minute time delay

between modes and when re--entering a mode. The G command

calls for ventilation, the Y1, Y2, and Y3 commands call for

cooling, and the W1 & W2 commands call for heating. Thermostat

Contro l Type (THERMOSTAT TYPE) affects how cooling

operates based on Y1, Y2, and Y3 commands and if

cooling/heating stage time guards are applied.

When space temperature sensor control in enabled (UNIT

CONTROL TYPE), the unit will try to maintain the Space

Temperature (SPACE TEMPERATURE) between the effective

Loading...

Loading...