9

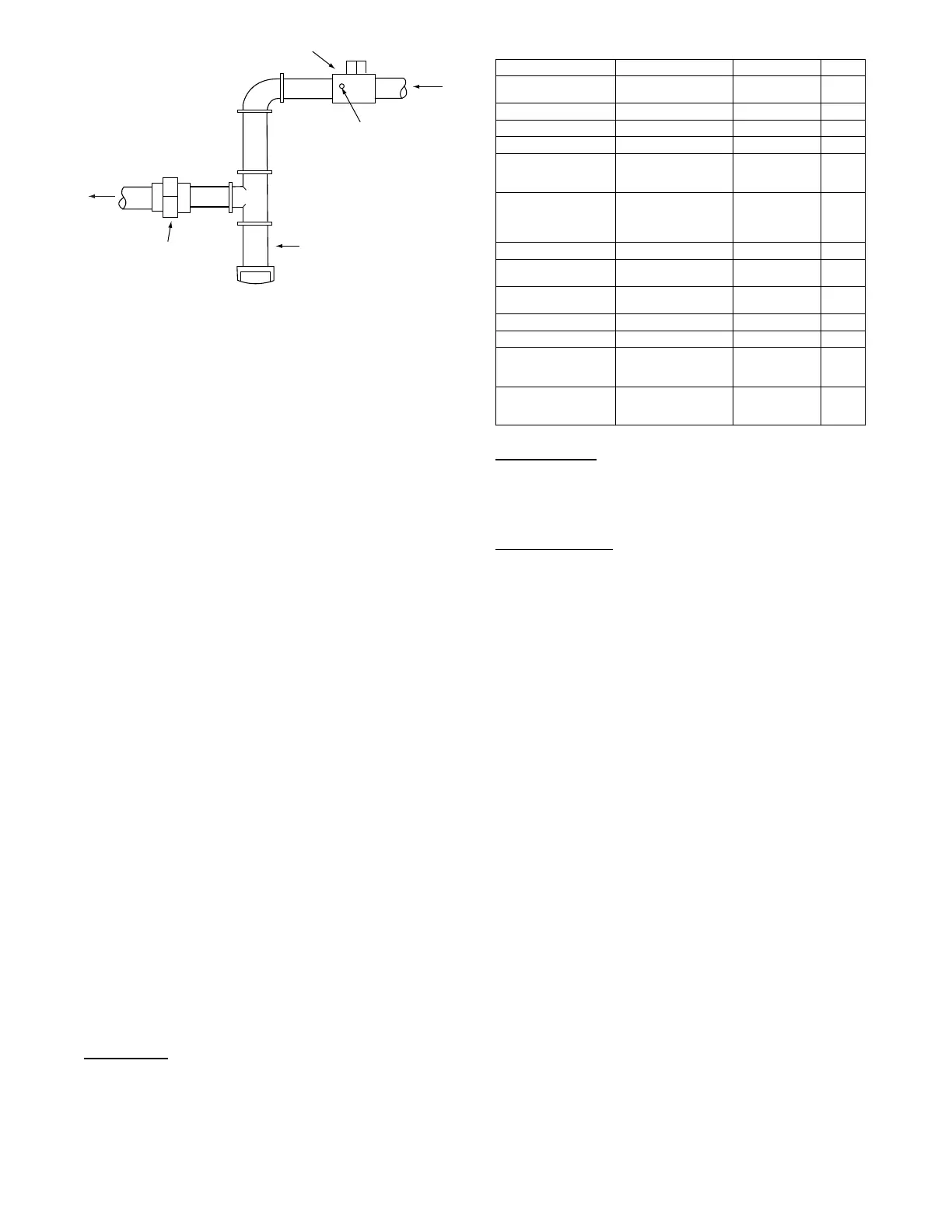

MANUAL GAS SHUT OFF VALVE

(FIELD SUPPLIED)

SUPPLY GAS

PRESSURE TAP

(1/8˝ NPT PLUG)

GAS

SUPPL

SEDIMENT TRAP

UNION

TO

UNIT

a48---9382

Fig. 9 -- Field Gas Piping

3. Connect a pressure gauge to the manifold pressure tap on

the burner assembly located inside the unit.

4. Ope n the field-s upplied manua l gas shut off va l ve. Ente r

Service T est mode by setting TEST MODE to “ON” using the

SystemVut controller interface. Use the Service Test feature

to set HEA T 1 TEST to ON (firs t stage of heat) using the

SystemV u controller interface.

5. After the unit has run for several minutes, verify the supply

gas pressure is adequate per the base unit installation in-

structions. If not, adjust accordingly .

NOTE: Supply gas pressure must not exceed 13.0--in. wg.

6. Set HEAT 1 TES T to OFF using the SystemVu controller

interface.

7. Exit Service Test mode by setting TEST MODE to “OFF”

using the SystemVu controller interface.

CONTROLS QUICK SET--UP

The following information will provide a quick guide to setting up

and conf iguring the 48/50LC series units wi t h Syst emVu control s.

Unit cont r ols are pre - configured a t the fa ctory for factory-installed

options. Field-installed accessories will require configuration at

start-up. Initial System Startup is recommended for initial start--up.

Additionally, specific job re quirem ents may re quire changes to default

configuration val ues. See Appe ndi x A and othe r s ecti ons of these

instructions for mor e det ails . Ref er to the Ma jor System Component s

or accessory installation instructions for specific wiring detail.

Control Set Point and Configuration Log

During start up, accessory installation, and equipment service set

points and/or configuration changes might have to be made. When

setting set points or configuration settings, documentation is

recommend. The Control Set Point and Configuration Log starting

on page 153 should be filled out and left with the unit at all times,

a copy should also be provided to the equipment owner. A USB

jump drive can be used to back up the unit’s configurations. Refer

to the USB Operation section for details.

Initial Startup

Initial Startup refers to the first time this particular unit has a startup

performed. The SystemVu controller will continually display the

Initial Startup prompt until it is completed. To complete the initial

startup you must complete the Quick Setup, Network Setup, and

the System Auto Test.

Quick Setup

This a list of common adjusted configurations set during startup.

These are common accessories, and control means. Set the list in

Table 3. After setting these per the specific unit set the QUICK

SET CHKLIST point to done.

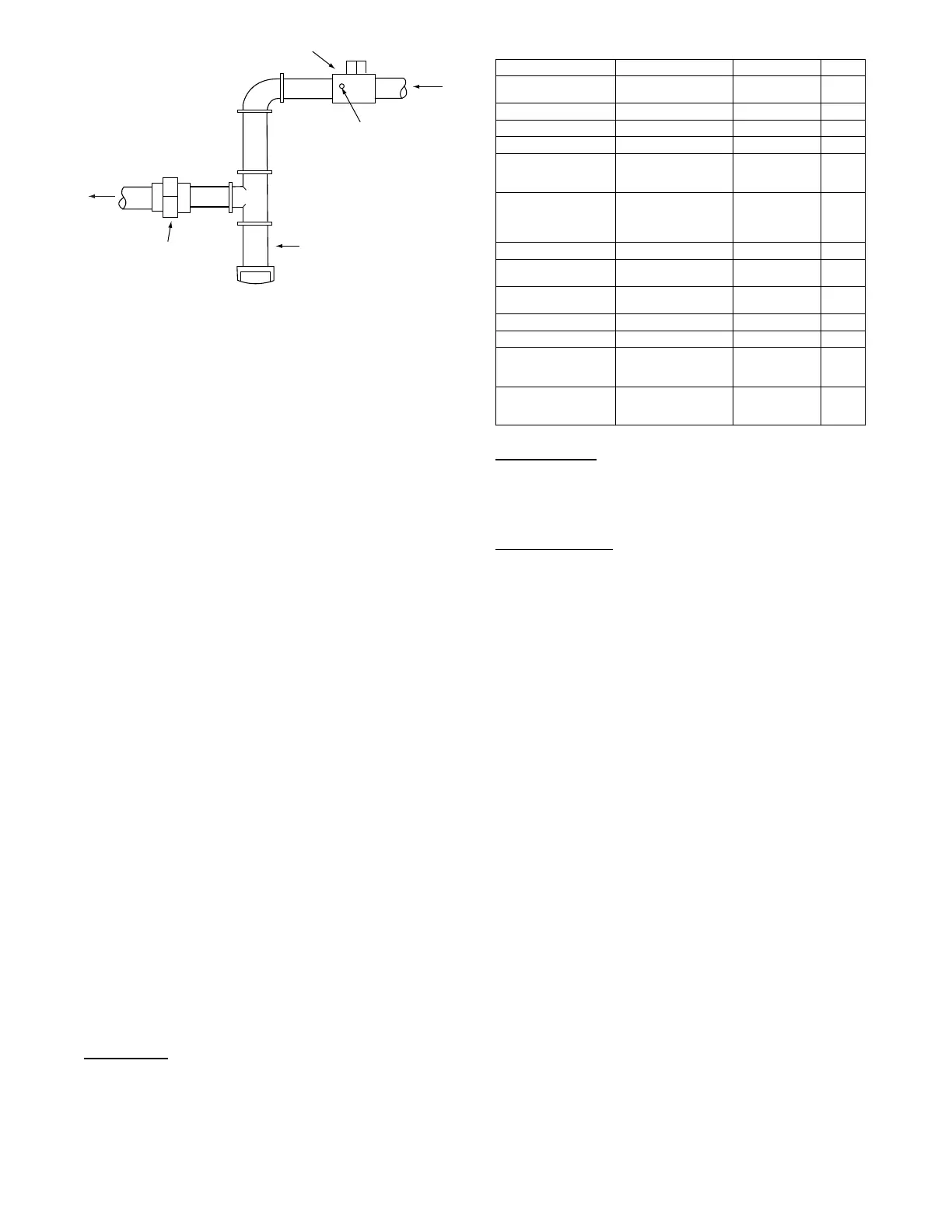

Table 3 – Quick Setup Menu Items

SystemVu™ Display Expanded Name Range Default

QUICK SETUP CONFIG QUICK SETUP

CONFIG MENU

TIME Clock Hour and Minute HH:MM

DATE Current Date MM/DD/YYYY

STARTUP DELAY Unit Startup Delay 10 to 600 30

UNIT CONTROL TYPE Unit Control Type 0=TSTAT,

1=SPACE SEN,

2=RAT SEN

0

THERMOSTAT TYPE Thermostat Hardware

Type

0=CONV 2C2H,

1=DIGI 2C2H,

2=CONV 3C2H,

3=DIGI 3C2H

2

DIRTY FILTER TIME Change Filter Timer 0to9999 600

VENT IDF SPEED Ventilation Only IDF

Speed

0to100 67*

HEATINGSTAGQTY Number of Heating

Stages

1to2 2*

ECON INSTALLED? Economizer Install ed? No/Yes No*

FREECOOL MAX OAT Free Cooling Max OAT 0to90 65

FIRE SHUTDOWN SW Fire Shutdown Switch 0=No Switch,

1=N/Open

2=N/Close

0*

QUICK SET CHKLIST QUICK SETUP

CHECKLIST

0=Undone,

1=View,

2=Done

0

* These defaults change based on the Unit model number.

Network Setup

This is a shortcut to the Network Settings submenu. In this sub

menu are the specific network settings required to get the network

piece up and running. After setting these per the specific unit set

the NETWORK CHKLIST point to done.

System Auto Test

Turning this to Start will run enable test mode and execute the System

Auto Test. Af ter the auto test has completed, set thi s to done .

Thermostat Control

Wire accessory thermostat to the corresponding R, Y1, Y2, Y3,

W1, W2, and G terminals on the Main Base board.

The Unit Control Type configuration, (UNIT CONTROL TYPE)

default value is for thermostat (0) so there is no need to configure

this item.

The Thermostat Hardware Type, (THERMOSTAT TYPE) selects

the unit response to the thermostat inputs above.

NOTE: May not be compatible with heat anticipator thermostats.

Space Temperature Sensor Control -- Direct Wired

(T--55 or T--56 or T--59)

Wire accessory space temperature sensor(s) to the T-55 terminals

on the field connection terminal board located at the unit control

box. Refer to Space Mounted Sensors sectio n (page 59) for

additional information.

The Unit Control Type configuration, (UNIT CONTROL TYPE)

must be set to Space Sensor (1).

Space Humidistat Control

For units with the factory--installed Humidi--MiZer

R

system

option, the humidistat input is provided with quick connects. The

Space Humidity Switch configuration, SETTINGS UNIT

CONFIGURATIONS SWITCH INPUTS CONFIGS

HUMSTAT CHANNEL identifies the normally open or normally

closed status of this input at HIGH humidity.

Relative Humidity Sensor Control

For units with the factory--installed Humidi--MiZer system option,

the humidity sensor input is provided with quick connects. The

sensor can be used instead of a humidistat. The RH Sensor

configuration, SETTINGS UNIT CONFIGURATIONS

ANALOG INPUTS CONFIGS SPRH SENSOR CHANNEL,

identifies the point on the MBB (Main Base board) or the IOB

(Input Output board) the sensor was wired into.

Loading...

Loading...