28

referred to as start bias time, or bias time. The algorithm to

calculate this bias time is called Temperature Compensated Start.

This is required for ASHRAE 90.1 compliance. When temperature

compensated start is running (TCS ACTIVE?) the control uses the

occupied set points to control the space.

When Temperature compensated start is enabled (ADAPTIVE

TCS?), no other configuration parameters are needed for this

algorithm, because the algorithm will automatically adjust the Bias

Time based on the data collected during the period of last time

optimal start. The inputs to the calculation algorithm includes space

temperature, unoccupied set points, occupied set points, outdoor air

temperature, and supply air temperature. Bias time is changed

dynamically per RTU operation.

When Temperature compensated start is disabled (ADAPTIVE

TCS?), the control will use the User Temperature compensated

Start bias time (USER TCS BIASTIME) in determining when to

start controlling to the occupied set points. If the User Temperature

compensated Start bias time (USER TCS BIASTIME) is set to

zero, the control will switch to the occupied setpoints at the time of

occupancy.

Linkage

The SystemVut controller will support 3Vt, VAV a n d V VT

R

zoning system on a CCN system or Open VVT and VAV systems

on a BACnet MS/TP System. All that is required is to configure

the Open or 3V Master zone to use the SystemVu rooftop unit as

its airsource. The SystemVu control will need to be configured for

the proper network protocol (BAS PROTOCOL) and set for Space

Sensor Control (UNIT CTRL TYPE). The SystemVu controller

will reply to the zoning system and change its operating parameters

to meet the demand of the zoning system. Status of this process can

be viewed in the airside linkage tab of the property pages in the

i-- Vu

R

application or by viewing the linkage maintenance table

with a CCN tool.

Carrier Comfort Network

R

(CCN) Operation

The SystemVu controller can be configured to connect to a CCN

system. The SystemVu controller h as one RS-- 485 BMS port that

can be configured fro m the local display for BACnet or CCN. The

BMS configuration parameters can be found in the

SETTINGSNETWORK SETTINGS submenu. The first

configuration is the BMS system for CCN systems change this

configuration from BACnet to CCN then set the CCN BAUD rate,

the bus and element number and you will be able to find the

controller with any CCN tool then upload the CCN tables in the

controller for use by the tool.

BACnet Network Operation

The Syste mVut controller is ready to connect to BACnet. The

SystemVu controll er has one RS--485 BMS port tha t ca n be

configure d from the loca l dis play for BA Cne t or CCN. The default

setting is BACnet and the Default BACnet Baud rate is 76800. These

setting are found on t he SETTINGSNETWORK SETTI NGS sub

me nu of the loc al displ ay . There ar e four other settings for i--Vu

compatibility and for setting the device ID and MAC address of the

controll er. See the table below for assistance.

Before connecting to the BACnet system determine the system

requirements and use the follo wing guide to configure the BACnet

settings. Then power the controller down, connect to the BACnet

MS/TP network and you are ready to discover your controller.

For i--Vu

R

systems with auto addressing desired the controller is

already set with the defaults from the factory ready to connect to

this type of system; just set the MAC address of the controller from

0 to 99 and then power down and connect to the network. The

router will find and send the network number to the controller and

the controller will set it device ID with the network base appended

by the Mac address.

For i--V u and other BACnet systems when it is required to send the

device ID to the controller change the ALC/i--Vu auto ID scheme to

no and set the MAC address from 0 to 99 like before. Then connect to

the network and write the device ID to the controller at the MAC

address you set. The controller will accept and retain the device ID

written to the device Id property of the object ID.

To manually set the device ID from the loc al display set the BACne t

auto/ma nual to ma nual. This allows use of the full range of 1 to 127

for the MAC address and set the device ID in the BACne t ID

selection of the local display. It can only be set from the local display

and will not accept a write to the device ID property in the object ID.

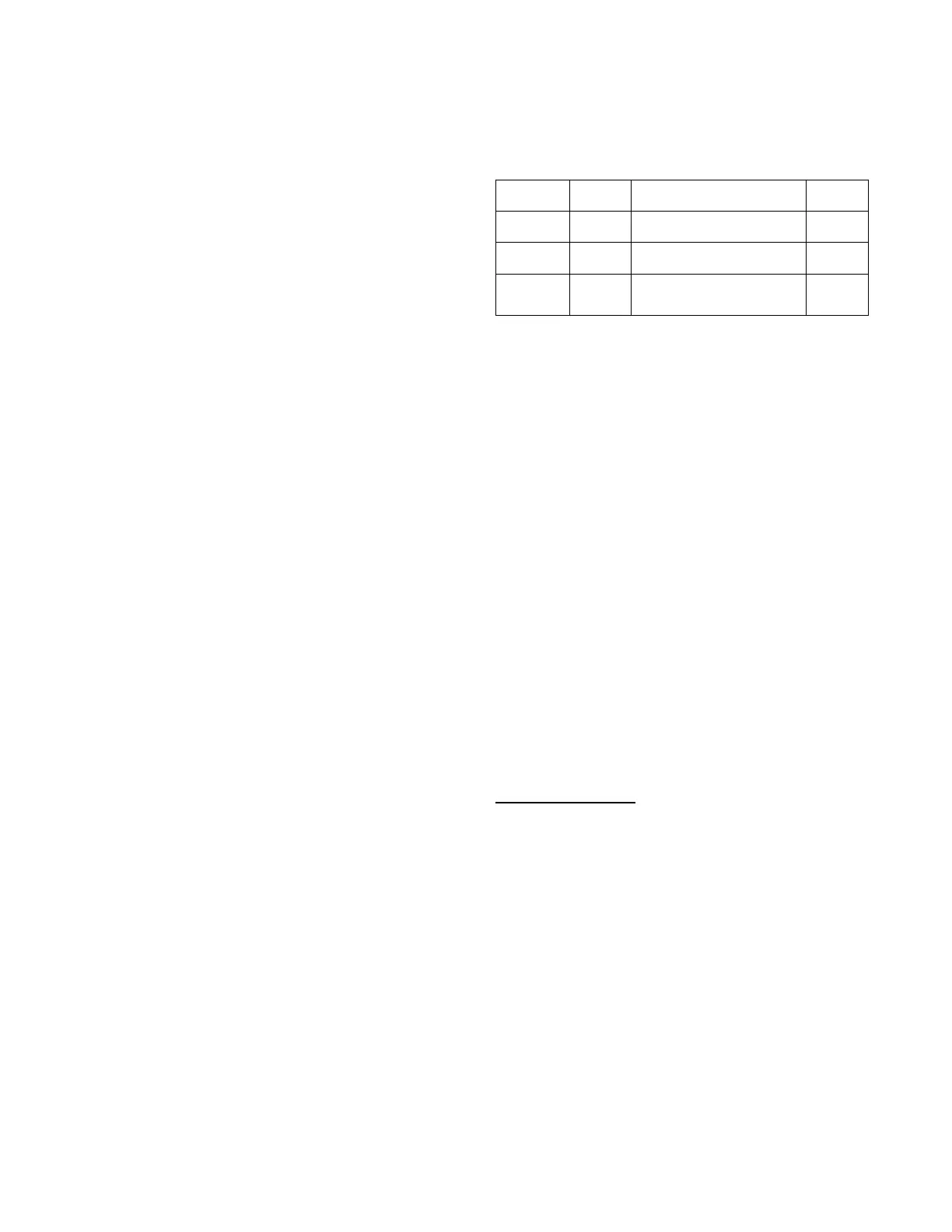

BACnet ID

Auto/Manual

I --- V u A u t o

Scheme

How Device is derived

MAC

range

Manual ON or OFF

Local display BAC net Id--- BACNet

Writes not allowed

0 --- 1 2 7

Auto OFF

Devic e Id Prefix + Mac --- BACnet

writes allowed

0 --- 9 9

Auto ON

Device Id Prefix + MAC (prefix updat-

ed by color cache) --- BACnet writes

not allowed

0 --- 9 9

Alarm Handling

There are a variety of different alerts and faults in the system, the term

alarm is used to reference alerts and faults. Alerts are indicated by

AXXX (wher e XXX is the al e r t number) on the displa y and gene r a ll y

signify a warning of some sor t or the impr operly functioni ng circuit

can re start without human int eraction. If an fault occurs, indic ate d by

FXXX (whe re XXX is the f ault number ), a major function of the unit

is inope rable or the dama ged ci rc uit will gene rally not restart wi t hout

an alarm reset via the display or CCN.

The response of the c ontrol s ystem to va rious al erts and fa ults de pends

on the seriousness of the particular alert or fault. In the mildest case, an

alert does not affe ct the oper ation of the unit in any manner. An al ert

can also cause a “strike.” A “striking” alert will cause the circuit to

shut down for 15 minut es. This feature reduces the l i kelihood of fa ls e

alarm s causing a prope rly working system to be shut down inc orrectly.

If t hree st rikes oc cur before the circuit has an opport unity to show that

it can function properly , the circuit will strike out, causing the

shutdown fault for t hat par ticular ci rcuit. Once activated, t he shutdown

fault can only be cleared via an alarm reset.

Howe ver , c ircuits with strike s will be given an opportunity to rese t

their st rike count er to zero. As dis cussed above , a strike typically

cause s the cir cuit to shut down. Fif teen minutes later, that circuit wil l

once again be allowed to run. If the “troubled” circuit runs

continuously for a use r def ined ti me (SETTI NGSUNIT

CONFIGURATIONSCOOLINGSTRI KE CLEAR TIME) with

no detectable probl ems the st rike count er will be res et to ze ro. Default

value is 5 minut es.

Alarm Relay Output

The al arm relay output is a configurable nor mally open 24--VAC

output de faulted to r e lay 11 on the Main Bas e Board ( MBB) TB2

connector . Selection of which alerts and faults will result in closing of

the alarm relay may be se t in the Alarm Rel ay Confi guration

(SETTINGS UNIT CONFIGURATIONSALARM RELA Y).

Setting a configuration to YES will result in the alarm output relay to

energize when that particular condition is in an alarm state. Setting a

configuration to NO will result in no ac t ion by the alarm output r elay

for that par ticular condit ion.

NOTE: An accessory filter switch can be used along with the

alarm relay output function to indicate dirty filter service need. See

the Troubleshooting section for more information on viewing,

diagnosing, and clearing alerts and alarms.

TROUBLESHOOTING

The Syste mVut dis play shows actual operating condi t ions of the unit

while it is running. If the re a r e alarms or the re have been alarms , they

will be displayed in either the active faults, active alerts, or the history

alarm list (see T able 13 starting on page 34). Service T est mode allows

proper operation of the compressors, fans, and other com ponents to be

checke d whi le the unit is not operati ng. See Se r vice Test (on page 1 1).

Loading...

Loading...