CAC Gasoline Engine Maintenance And Servicing Manual

37

——Check and make sure that the oil injection hole of the

connecting rod large end is not blocked. The outside diameter is

φ1mm.

Installation:

——Need not to divide into groups for the piston weight, piston

pin holes and the accessory piston skirt. Before assembling, check

the piston head mark and make sure that it is in accord with

cylinder No.4.

——Heat the small end of connecting rod to 230°—400℃, and

apply SAE50 engine oil or graphite colloid oil on the outer

circumference of the piston pin hole. Then press the piston pin

into the hole of connecting rod small end and piston pin. One end

of the piston pin may be 0.7mm mostly out of the pin hole or

0.3mm mostly in the seat. And plug the other end of it into the pin

seat.

The piston head means the front arrow. The outer end of

piston pin means the front lug, which should has a same

direction with “F” near the large end of the connecting

rod.(with ‘480’ mark on some blanks and the mark side

forward.)

——After the piston, piston pin, and the connecting rod are put

together, print and sculpture the cylinder numbers with the 3mm

words on the top of piston, the connecting rod and the left side of

rod cap(viewed from the front). Be sure not to be deformed on the

connecting side during printing.

——The dimension of piston ring.

478 piston ring 480 piston ring

Paint marker (group) Size of

gauge

Paint marker

(group)

Size of

gauge

Yellow paint +no paint

(standard)

77.22 No paint

(standard)

79.94

Yellow paint+ purple

paint (oversize 0.29)

77.51 Purple paint

(oversize 0.29)

80.23

Yellow paint +blue

paint (oversize 0.5)

77.72 Blue paint

(oversize 0.5)

80.44

——

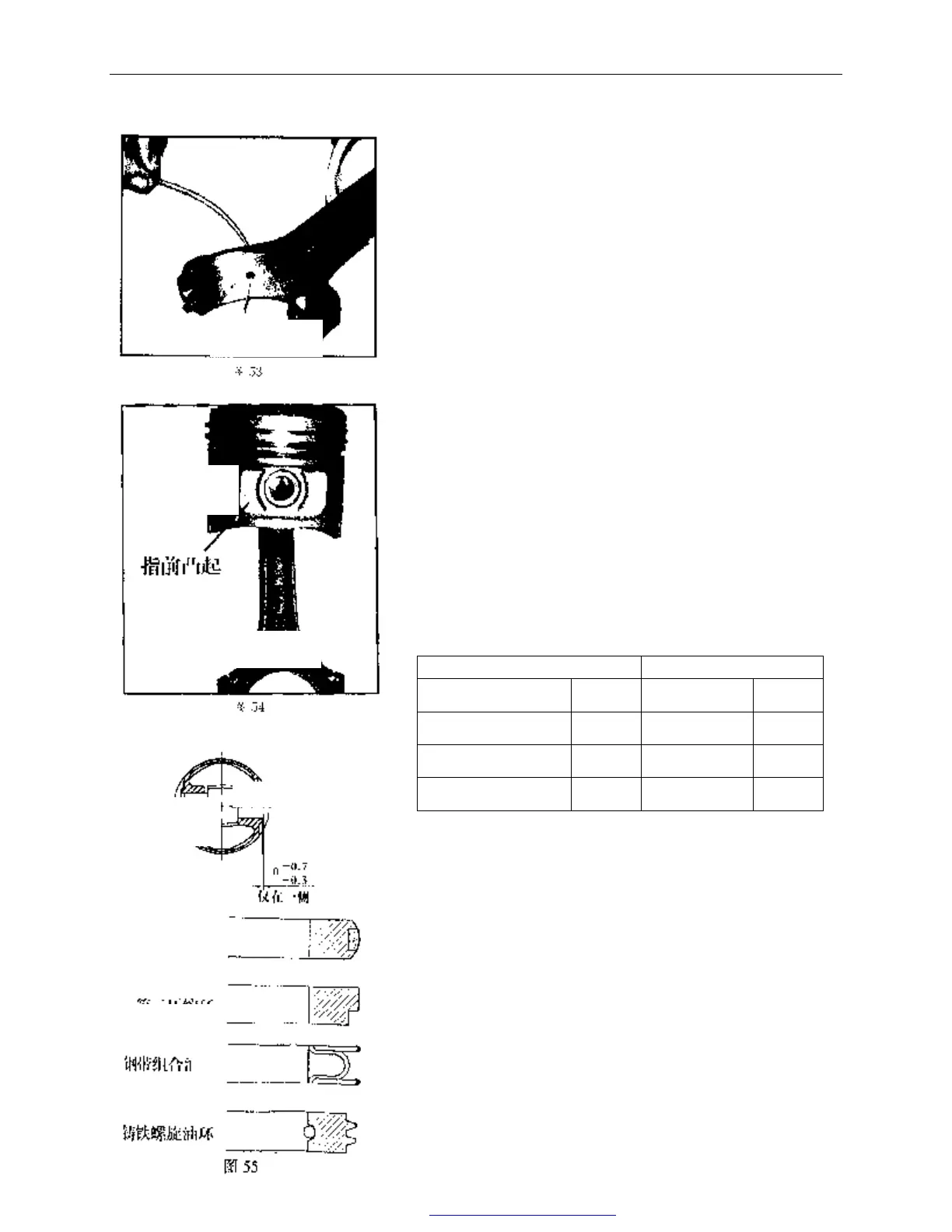

When installing the piston ring, the mark side should

be put up and the second compression ring outside cut section

should be put down and remember not to the contrary. Firstly the

oil controlling ring, then the second compression ring, and finally

the first compression ring. As assembling the ring, its maximum

tension should be inferior to the diameter of the cylinder(+1.

65mm), or the ring would be deformed and broken. The two

cotters of the steel band combination oil ring and oil control

spacer ring should be parted with a angle of 120°. And the

cotters of cast iron oil ring and screw spacer ring should be parted

with a interval of 180°. The piston should rotate freely in the ring

groove without blocking.

Fig.53

Fig.54

Fig.55

Front

ring

ring

Cost iron oil ring

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

Loading...

Loading...