3.16 - Time management

The date and time are set using parameters P102 and P103. The date uses weekly/annual programming,

and stores the time at which a fault occurred.

The PLC contains a battery to prevent the time being wiped in the event of a power cut. If the time is not stored after a power cut,

the battery needs to be changed (service life of approximately 10 years – varies according to ambient conditions).

102 Date

103 Time

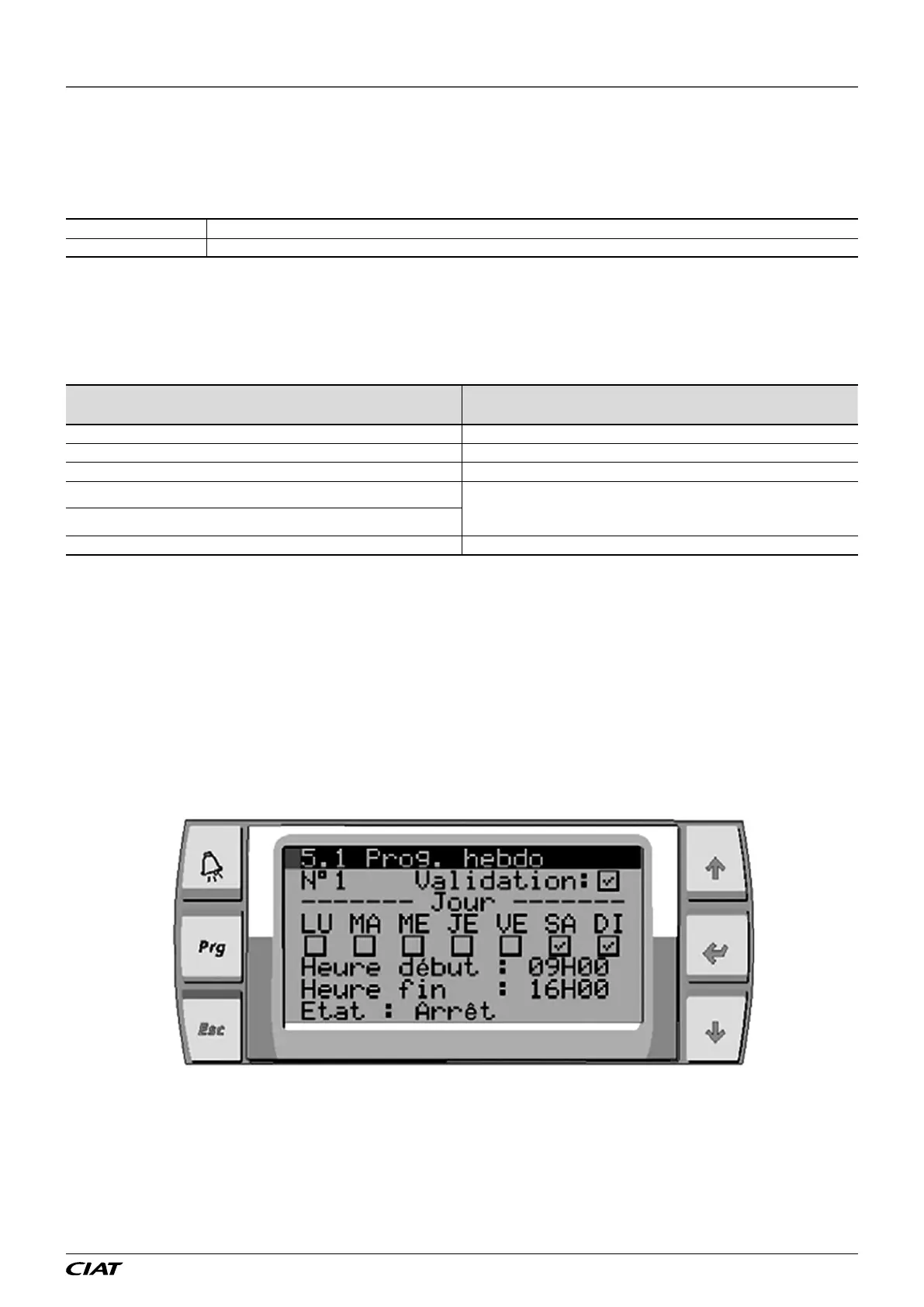

3.17 - Scheduling

The time schedule is used to change the unit's operating mode (o, setpoints 1, setpoints 2, frost protection, etc.) according to the

time, day of the week or the season.

The PLC authorises 6 periods of weekly programming and 6 periods of annual programming, which may overlap and be individually

validated.

Requested state Display condition

O

Frost protection P154 Target temperature selection = room

Night cooling (programmed weekly only) P151 Night cooling = with

On setpoint 1

P160 Setpoint 1/Setpoint 2 selection = terminal or CMS

P160 Setpoint 1/Setpoint 2 selection = terminal or CMS, or On/

O input only or On/O input forcing

On setpoint 2

On P160 Setpoint 1/Setpoint 2 selection = without

In weekly programming, when the ranges overlap, the priority, from to least important, is as follows:

1. O

2. Frost protection

3. Night cooling

4. On setpoint 2

In annual programming, when the ranges overlap, the priority, from most to least important, is as follows:

1. O

2. Frost protection

3. On setpoint 2

4. Weekly prog.

The annual programming takes priority over the weekly programming. Example of weekly programming:

Programmed shutdown of the unit, every Saturday and Sunday, 09:00 - 16:00.

3 - FEATURES

EN-25 FLOWAY ACCESS

Loading...

Loading...