4 - MANAGING A NETWORK OF CONTROLLERS AND HMI TERMINALS

To establish communication between controllers and terminals,

it is necessary to give an address to each of the elements.

This addressing is performed at the factory, but if a defective

component is replaced (controller or terminal), it may have to be

performed on site.

4.1 - One controller and one terminal:

The terminal addressing procedure is described in the following

section, paragraph 5.4.3. The procedure for the controller is in

paragraph 5.4.3. The controller and terminal must have dierent

addresses. The example opposite shows one addressing option

Terminal address: 32

Controller address: 01

P01 : Adr Priv/Shared

Trm1 : 32 Pr

Trm2 : None Sh

Trm3 : None --OK?

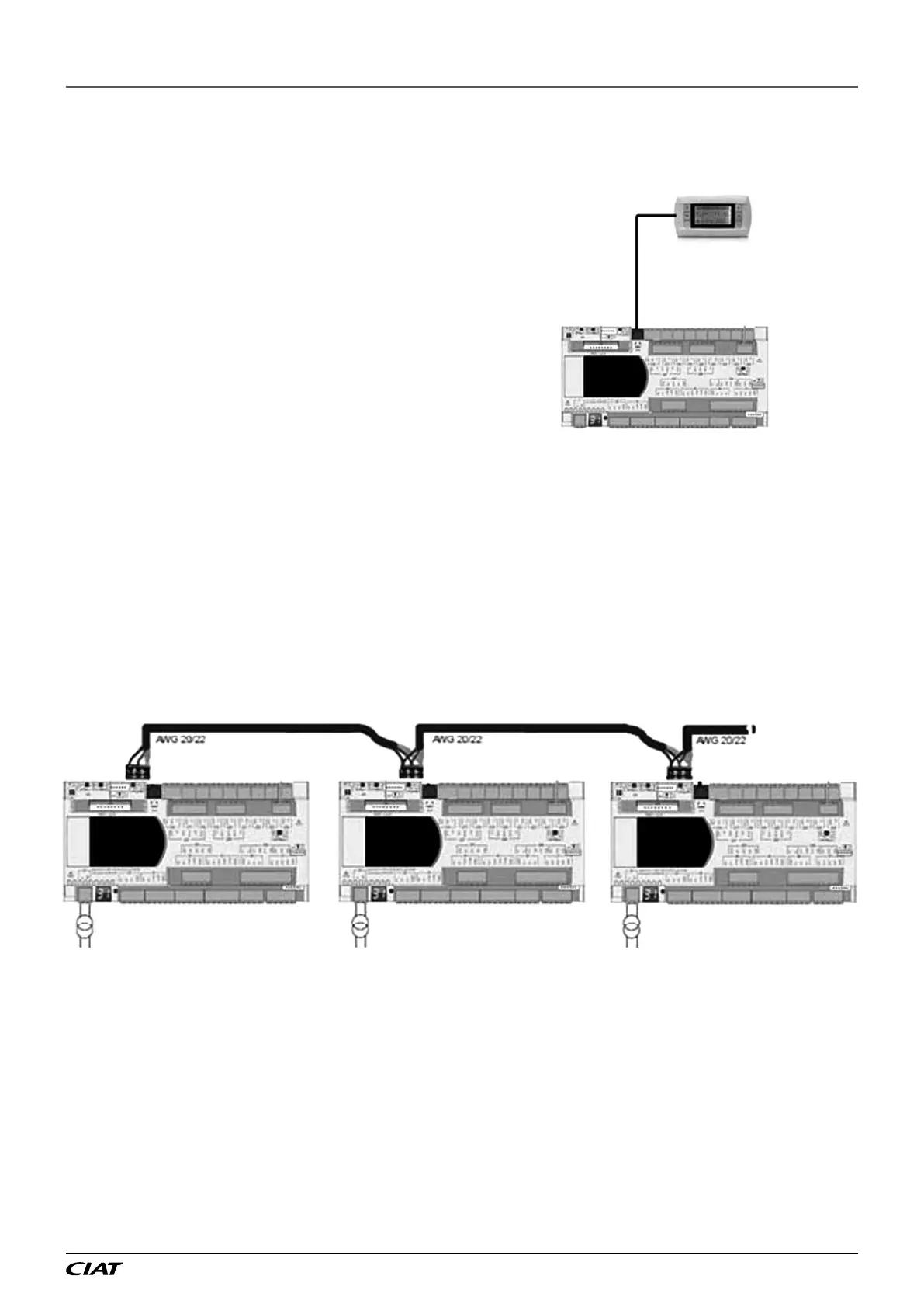

4.2 - Several controllers and terminals:

Several terminals or controllers may be interconnected, without any additional components, using the pLAN (local area network).

This enables several terminals to be used to display the parameters from one controller or, conversely, one terminal can be used

to display the parameters from several controllers.

Only the electrical connection and conguration of the addresses need to be performed by the user.

4.3 - Electrical connections for the pLAN (local area network)

4.3.1 - Connecting controllers to the pLAN

The electrical connection between the controllers in the pLAN (RS485) is installed using an AWG20/22 shielded cable composed

of a twisted pair and a shield. The cards must be connected in parallel using the J14 connector.

The rst and last controller must be no more than 500m apart.

EN-27 FLOWAY ACCESS

Loading...

Loading...