ENGLISH

GB

69

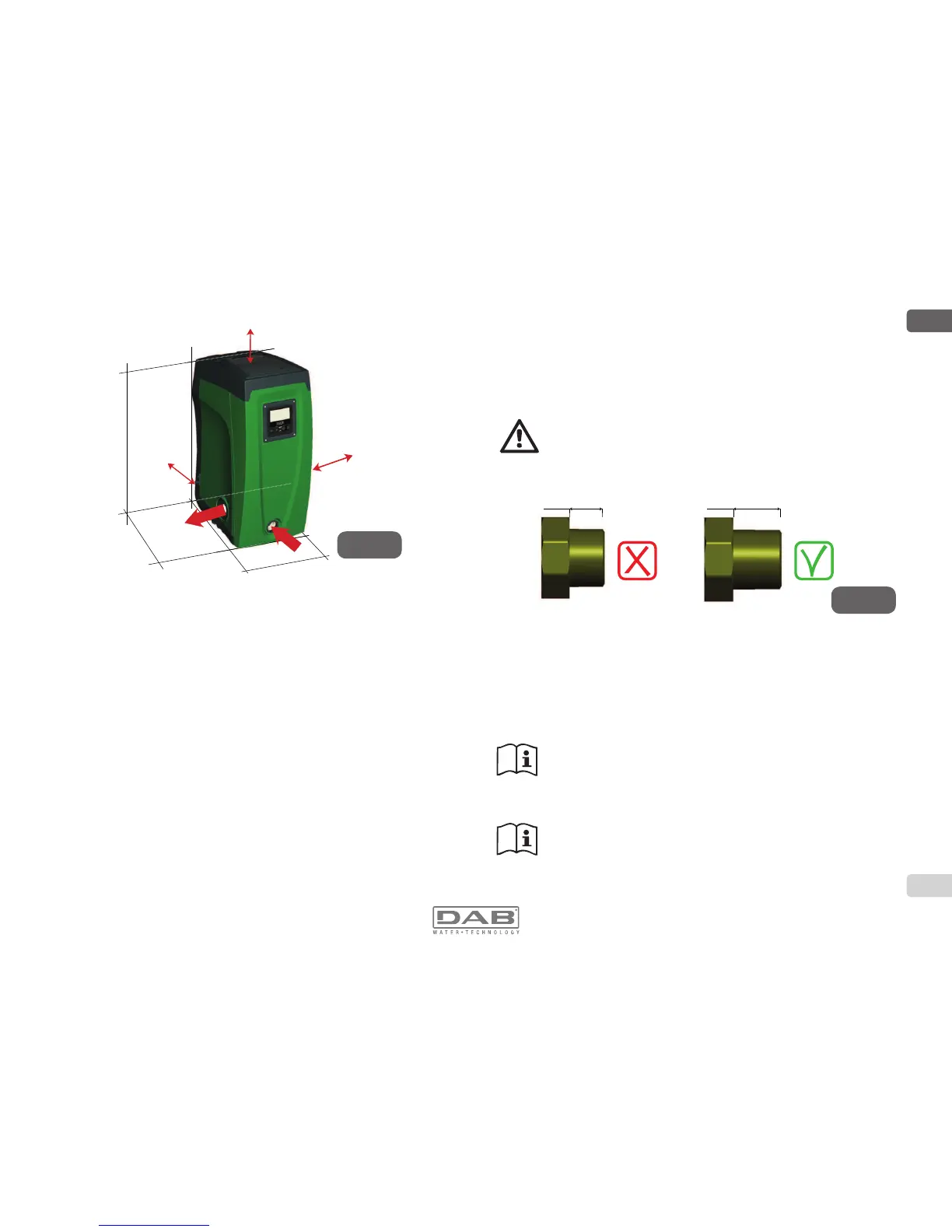

7KHGLVWDQFHRIDWOHDVWPPEHWZHHQ)DFH(RIWKH

system and any wall is obligatory to ensure ventilation

through the grids provided.

7KHGLVWDQFHRIDWOHDVWPPEHWZHHQ)DFH%RIWKHV\VWHP

and an obstruction is recommended so as to be able to carry out

maintenance on the non-return valve without disconnecting the

system.

7KHGLVWDQFHRIDWOHDVWPPEHWZHHQ)DFH$RIWKHV\VWHP

and an obstruction is recommended so as to be able to remove

the door and gain access to the technical compartment.

,IWKHVXUIDFHLVQRWÀDWXQVFUHZWKHIRRWWKDWLVQRWWRXFKLQJDQGDGMXVW

its height until it contacts the surface so as to ensure the stability of the

system. The system must in fact be placed in a safe and stable position,

ensuring that its axis is vertical: it must not be in an inclined position.

2.1.1 Hydraulic connections

Make the connection at input to the system through the mouth on Face

F marked “IN” in Fig.8 (suction connection). Then remove the respective

cap with the aid of the accessory tool or with a screwdriver.

Make the connection at output from the system through the mouth on

7KHYROWDJHDQGIUHTXHQF\RQWKHSXPS¶VWHFKQLFDOGDWD

7KHHOHFWULFDOFRQQHFWLRQLVPDGHLQDGU\SODFHIDUIURP

DQ\SRVVLEOHÀRRGLQJ

The electrical system is provvided with a differential switch

ZLWK,ǻQP$DQGWKDWWKHHDUWKV\VWHPLVHI¿FLHQW

SXPSHGLQVWDOOD¿OWHURQWKHV\VWHPLQWDNHWKDWLVVXLWDEOHIRUFDWFKLQJ

7KHLQVWDOODWLRQRID¿OWHURQLQWDNHFDXVHVDGHFUHDVHRIWKH

FDXVHGE\WKH¿OWHULWVHOIJHQHUDOO\WKHJUHDWHUWKH¿OWHULQJ

&KRRVHWKHW\SHRIFRQ¿JXUDWLRQ\RXLQWHQGWRXVHYHUWLFDORUKRUL]RQWDO

2WKHUW\SHVRILQVWDOODWLRQFRQ¿JXUDWLRQDUHSRVVLEOHXVLQJ'$%DFFHV

9HUWLFDO&RQ¿JXUDWLRQ

w them fully into their brass seats on face C. Put the system in place,

10 mm

200 mm

270 mm

IN

OUT

580 mm

355 mm

265 mm

Figure 8

Face F marked “OUT” in Fig.8 (delivery connection). Then remove the

respective cap with the aid of the accessory tool or with a screwdriver.

All the hydraulic connections of the system to the plant to which it can be

connected are of the threaded female type 1” GAS, made of brass.

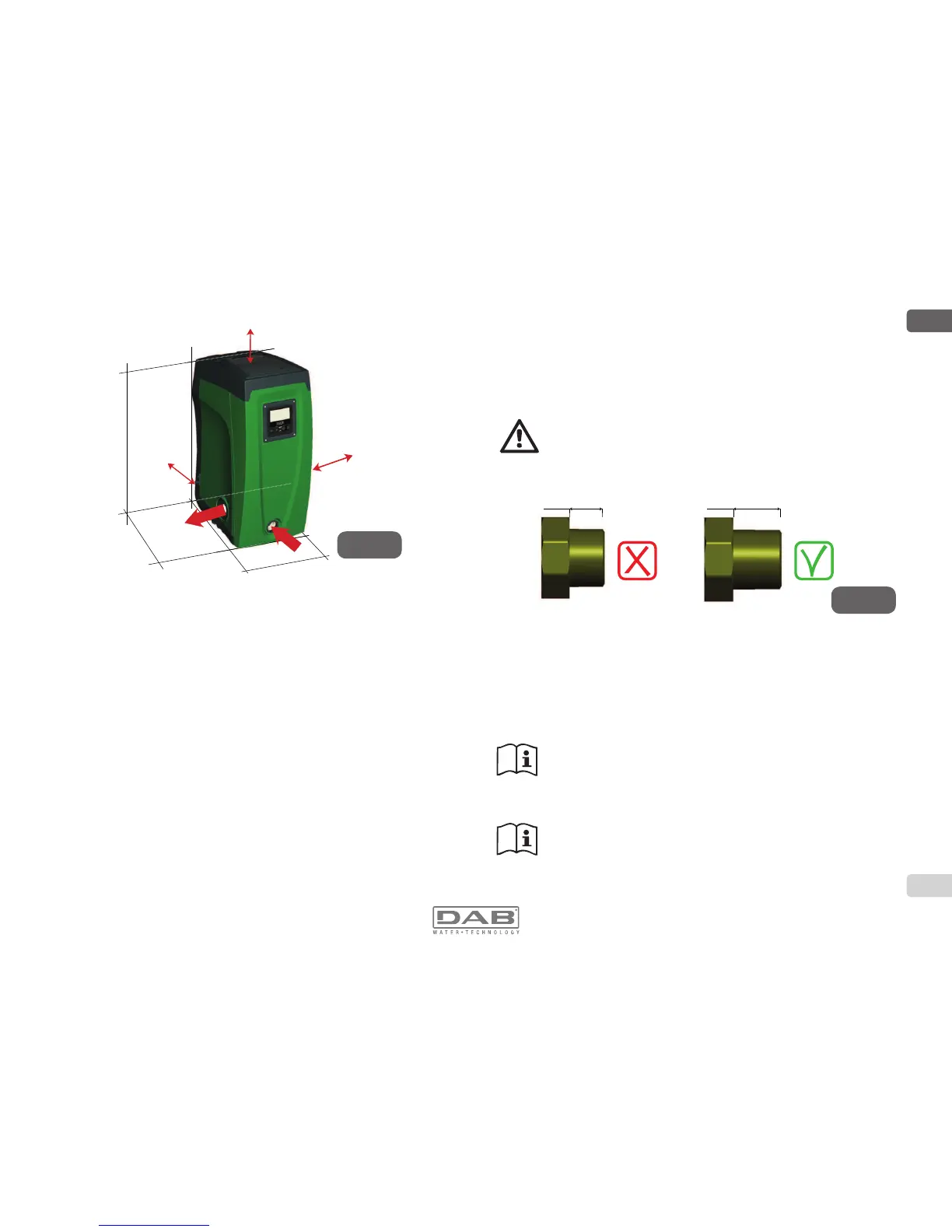

II\RXLQWHQGWRFRQQHFWWKHSURGXFWWRWKHSODQWZLWK¿WWLQJVWKDW

have a diameter larger than the normal 1” pipe (for example the

ULQJQXWLQWKHFDVHRI¿WWLQJVLQSLHFHVPDNHVXUHWKDWWKH´

Gas male thread of the coupling protrudes at least 25mm from

the above diameter (see Fig.9)

With reference to its position with respect to the water to be pumped, the

LQVWDOODWLRQRIWKHV\VWHPPD\EHGH¿QHG³DERYHKHDG´RU³EHORZKHDG´

,QSDUWLFXODUWKHLQVWDOODWLRQLVGH¿QHG³DERYHKHDG´ZKHQWKHSXPSLV

placed at a level higher than the water to be pumped (e.g. pump on the

surface and water in a well); vice versa it is “below head” when the pump

is placed at a level lower than the water to be pumped (e.g. overhead

cistern and pump below).

If the vertical installation of the system is of the “over head”

W\SHLWLVUHFRPPHQGHGWR¿WDQRQUHWXUQYDOYHLQWKHVXFWLRQ

section of the system; this is to allow the operation of loading

the system (par. 2.1.2).

If the installation is of the “over head” type, install the suction

pipe from the water source to the pump in such a way as to

avoid the formation of goosenecks or siphons. Do not place the

suction pipe above the pump level (to avoid the formation of air

bubbles in the suction pipe). The suction pipe must draw at its

< 25 mm > 25 mm

Figure 9

Loading...

Loading...