8 Test Procedures

8.1 Introduction

WARNING

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain

charged even when the drive is not powered. High

voltage can be present even when the warning LED

indicator lights are o. Failure to wait the specied time

after power has been removed before performing service

or repair work can result in death or serious injury.

•

Stop the motor.

•

Disconnect AC mains and remote DC-link power

supplies, including battery back-ups, UPS, and

DC-link connections to other drives.

•

Disconnect or lock the motor.

•

Disconnect any brake option.

•

Disconnect any regen/load share option.

•

Wait for the capacitors to discharge fully. The

minimum waiting time is specied in the

following discharge time table and is also

visible on the drive label.

•

Before performing any service or repair work,

use an appropriate voltage measuring device to

make sure that the capacitors are fully

discharged. For parallel drive modules, measure

DC-bus capacitor voltages before and after the

individual DC fuses.

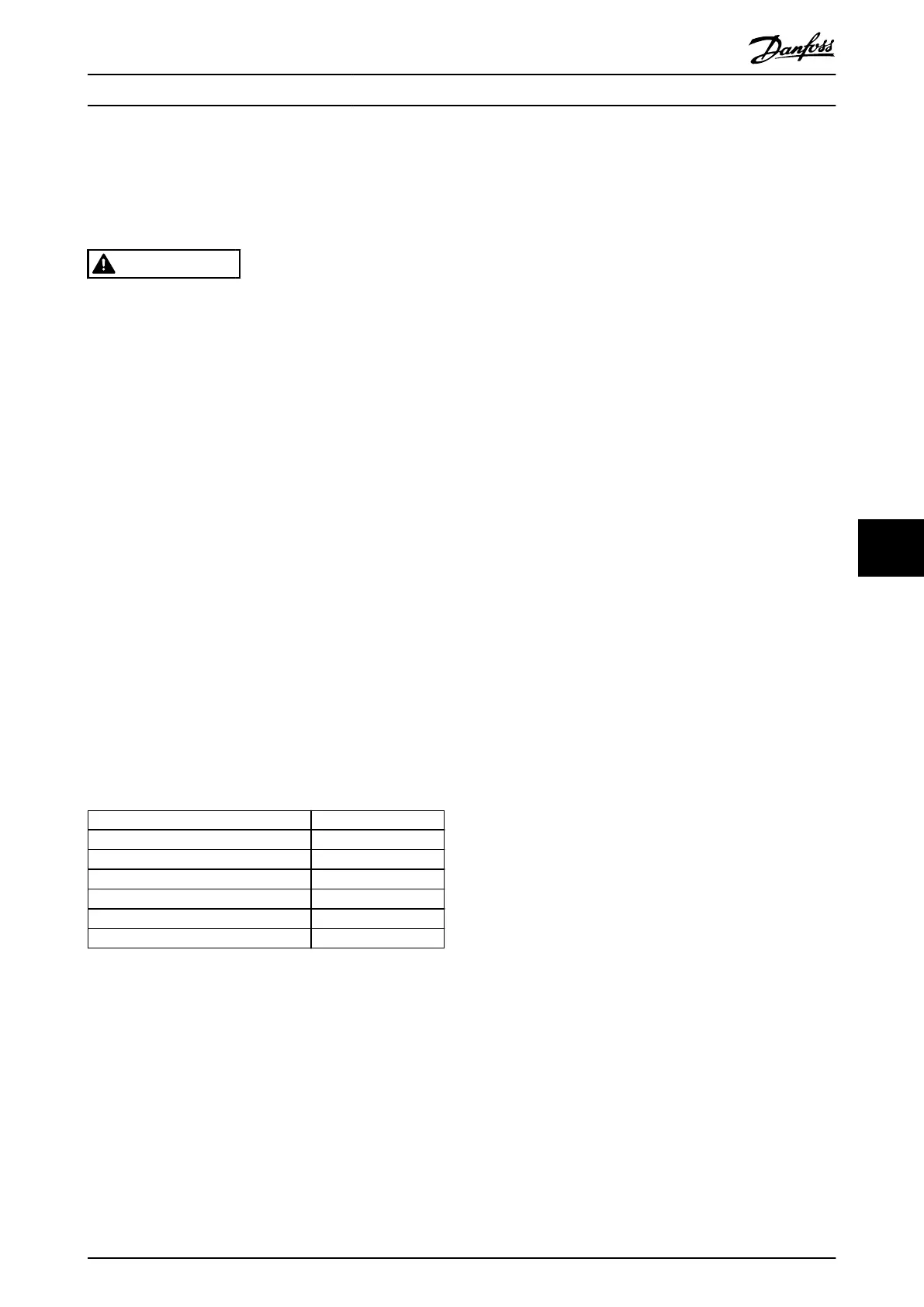

Enclosure Size Minimum waiting time

D1h–D8h drives 20 minutes

J8–J9 drives 20 minutes

D9h–D10h enclosed drive systems 20 minutes

Da2/Da4/Db2/Db4 parallel drive systems 20 minutes

E1h–E4h drives 40 minutes

E5h–E6h enclosed drive systems 40 minutes

Table 8.1 Discharge Time

This section contains detailed procedures for testing drives.

The results of these tests indicate the appropriate repair

actions. The source of fault conditions is not always

internal to the drive. For example, the drive monitors:

•

I/O signals.

•

Motor conditions.

•

AC and DC power.

•

Other functions.

Testing described in this chapter isolates many of these

conditions.

Drive testing is divided into 3 types:

•

Static tests.

•

Dynamic tests.

•

After-repair tests.

Static tests

Static tests are conducted without power applied to the

drive. Most drive problems can be diagnosed with these

tests. Static tests are performed with little or no

disassembly. The purpose of static testing is to check for

shorted power components. Perform these tests on any

unit suspected of containing faulty power components

before applying power.

Dynamic tests

Dynamic tests are performed with power applied to the

drive. Dynamic testing traces signal circuitry to isolate

faulty components.

After-repair tests

After-repair tests are performed following service work or

parts replacement. These procedures retest the drive with

the new component before power is applied.

Test Procedures Service Guide

MG94A502 Danfoss A/S © 02/2019 All rights reserved. 89

8 8

Loading...

Loading...