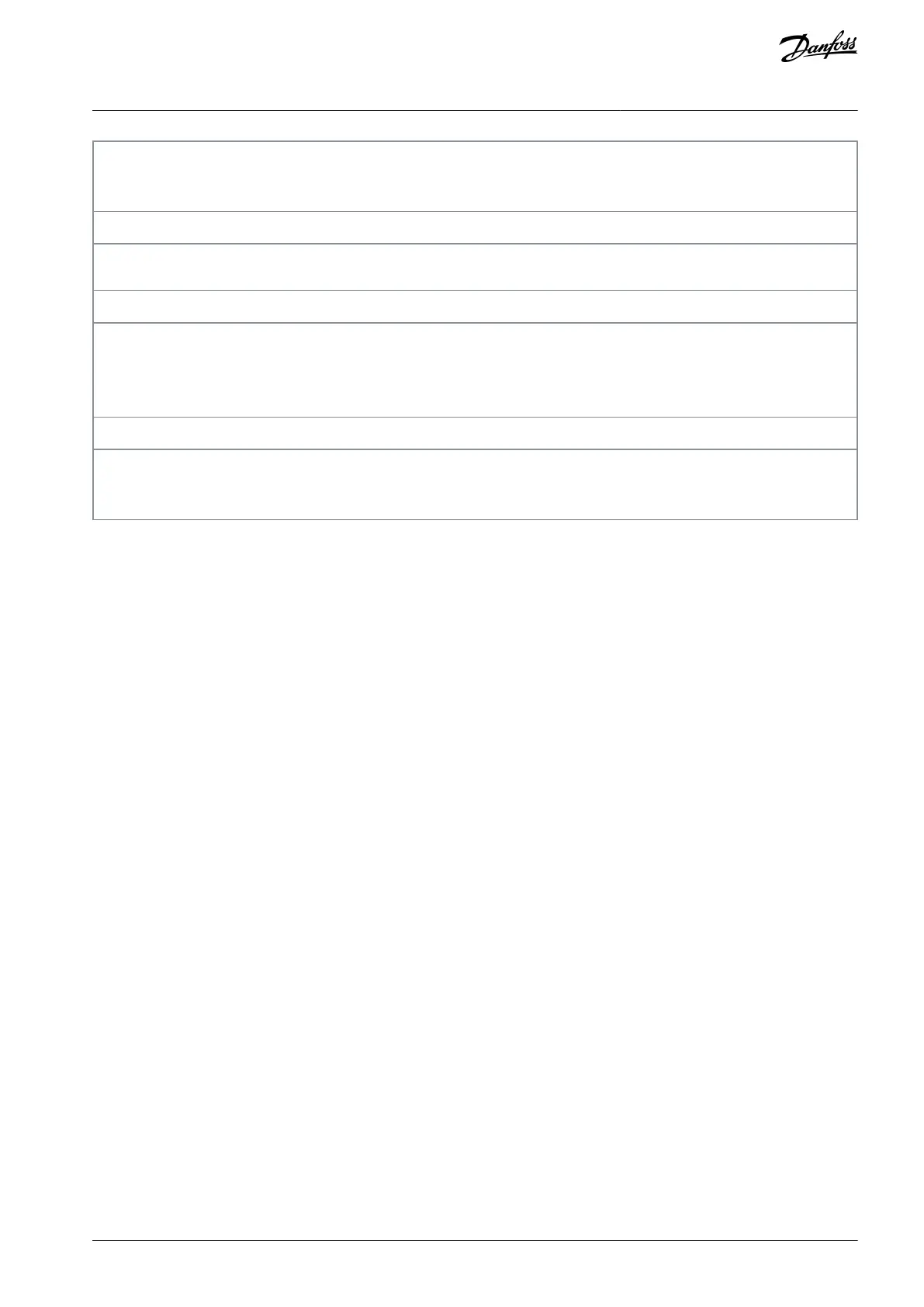

Look for any obstructions in the airow path.

Measure top and bottom clearance of the drive to verify that there is at least 225 mm (9 in) of clearance for adequate airow.

Check that requirements for ambient conditions are met. See the Ambient Conditions section.

Inspect that the unit interior is free of dirt, metal chips, moisture, and corrosion.

Verify that all installation tools have been removed from unit interior.

For enclosures with an IP20/Chassis protection rating, ensure that the unit is mounted to an unpainted metal surface.

Ensure that the unit is mounted solidly, or that shock mounts are used, if necessary.

Check for an unusual amount of vibration.

AQ357954340588en-000201 / 130R0881 | 97Danfoss A/S © 2020.09

Pre-start Check List

VLT® Refrigeration Drive FC 103

Operating Guide