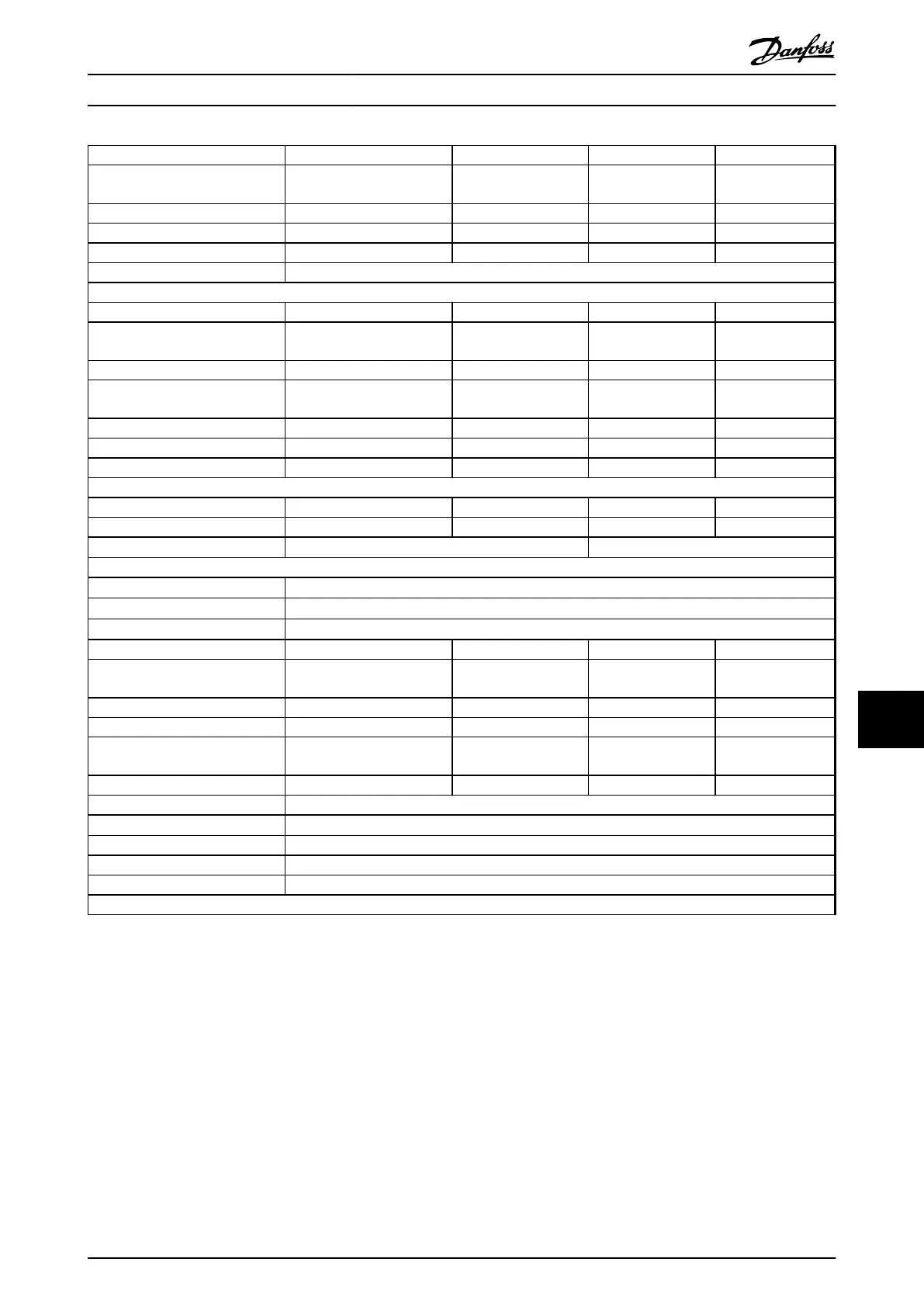

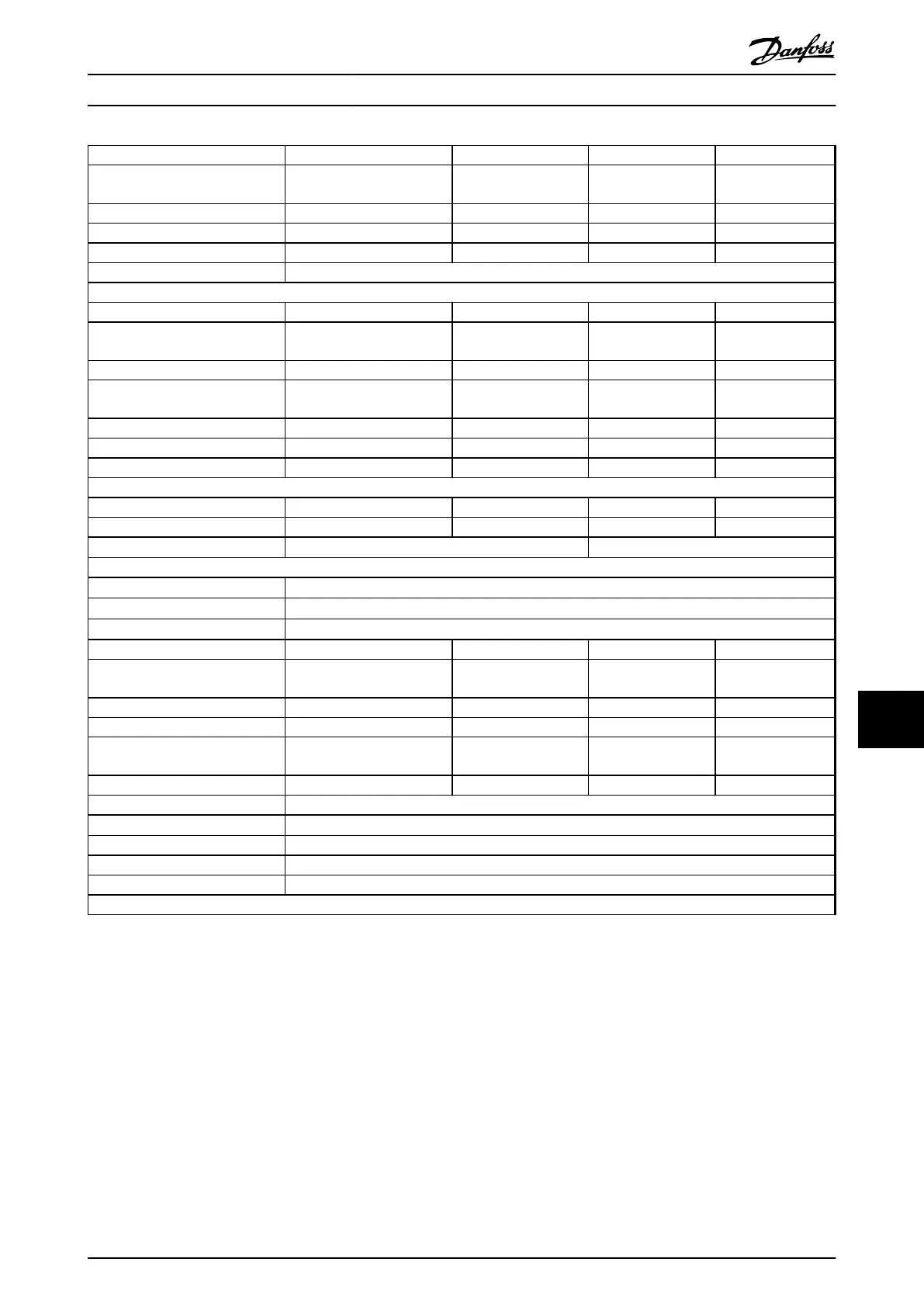

P500 P560 P630 P710

Normal Overload =110% current

for 60 s

NO NO NO NO

Typical shaft output at 400 V [kW] 500 560 630 710

Typical shaft output at 460 V [hp] 650 750 900 1000

Typical shaft output at 480 V [kW] 560 630 710 800

Enclosure IP21/54 F18

Output current

Continuous (at 400 V) [A] 880 990 1120 1260

Intermittent (60 s overload) (at 400

V) [A]

968 1089 1232 1386

Continuous (at 460/480 V) [A] 780 890 1050 1160

Intermittent (60 s overload) (at

460/480 V) [A]

858 979 1155 1276

Continuous kVA (at 400 V) [kVA] 610 686 776 873

Continuous kVA (at 460 V) [kVA] 621 709 837 924

Continuous kVA (at 480 V) [kVA] 675 771 909 1005

Max. Input current

Continuous (at 400 V) [A] 857 964 1090 1227

Continuous (at 460/480 V) [A] 759 867 1022 1129

Max. pre-fuses

1)

[A]

1600

2000

Max. cable size

Motor (mm

2

/AWG

2)

)

8 x 150 (8 x 300 mcm)

Mains (mm

2

/AWG

2)

)

8 x 240 (8 x 500 mcm)

Brake (mm

2

/AWG

2)

)

4 x 185 (4 x 350 mcm)

Total LHD loss 400 V AC [kW] 21909 24592 26640 30519

Total back channel loss 400 V AC

[kW]

17767 19984 21728 24936

Total filter loss 400 V AC [kW] 11747 12771 14128 15845

Total LHD loss 460 V AC [kW] 19896 22353 25030 27989

Total back channel loss 460 V AC

[kW]

16131 18175 20428 22897

Total filter loss 460 V AC [kW] 11020 11929 13435 14776

Weight, enclosure IP21, IP54 [kg] 2009

Efficiency

4)

0.96

Output frequency [Hz] 0-600

Heatsink overtemp. trip [°C] 105

Power card ambient trip [°C] 85

*Normal overload = 110% torque during 60 s

Table 11.3 Mains Supply 3x380-480 V AC

1) For type of fuse, see chapter 11.5.1 Fuses.

2) American wire gauge.

3) Measured using 5 m screened motor cables at rated load and rated frequency.

4) The typical power loss is at nominal load conditions and expected to be within ±15% (tolerence relates to

variety in voltage and cable conditions). Values are based on a typical motor efficiency (IE2/IE3 border line). Motors

with lower efficiency also add to the power loss in the frequency converter and opposite. If the switching

frequency is increased to the default setting, the power losses may rise significantly. LCP and typical control card

power consumptions are included. Further options and customer load may add up to 30 W to the losses. (Though

typical only 4 W extra for a fully loaded control card, or options for slot A or slot B, each).

Although measurements are made with state-of-the-art equipment, some measurement inaccuracy must be

allowed for (±5%).

Specifications

Operating Instructions

MG37A202 Danfoss A/S © Rev. 2014-07-29 All rights reserved. 141

11 11

Loading...

Loading...