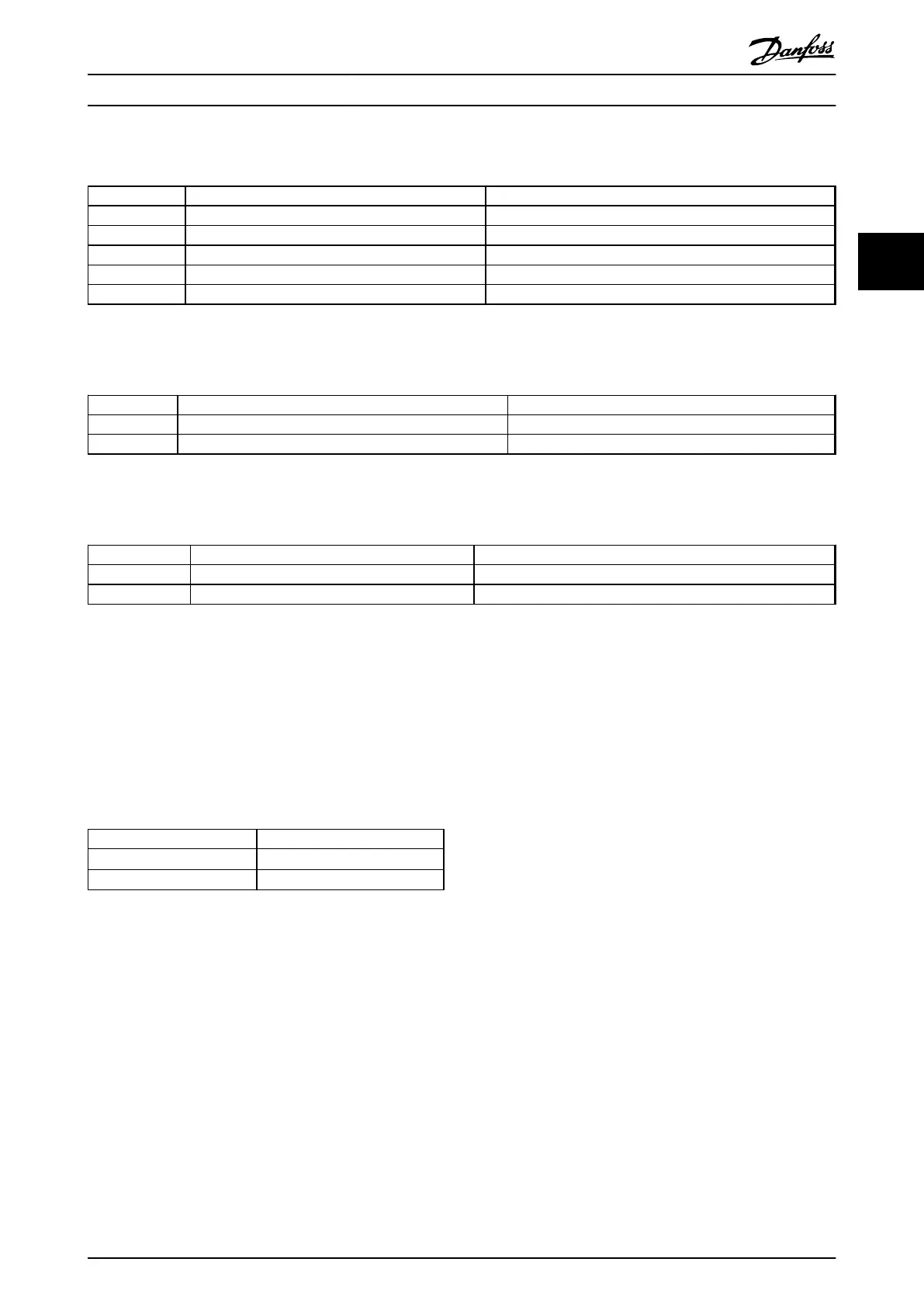

3.4.11 Mains Disconnects

Frame size Power & Voltage Type

D P132-P200 380–500 V OT400U12-9 or ABB OETL-NF400A

E P250 380-500 V ABB OETL-NF600A

E P315-P400 380-500 V ABB OETL-NF800A

F P450 380-500 V Merlin Gerin NPJF36000S12AAYP

F P500-P630 380-500 V Merlin Gerin NRK36000S20AAYP

Table 3.9 Recommended Mains Disconnects

3.4.12 F-Frame Circuit Breakers

Frame size Power & Voltage Type

F P450 380-500 V Merlin Gerin NPJF36120U31AABSCYP

F P500-P630 380-500 V Merlin Gerin NRJF36200U31AABSCYP

Table 3.10 Recommended Circuit Breakers

3.4.13 F-Frame Mains Contactors

Frame size Power & Voltage Type

F P450-P500 380-500 V Eaton XTCE650N22A

F P560-P630 380-500 V Eaton XTCEC14P22B

Table 3.11 Recommended Contactors

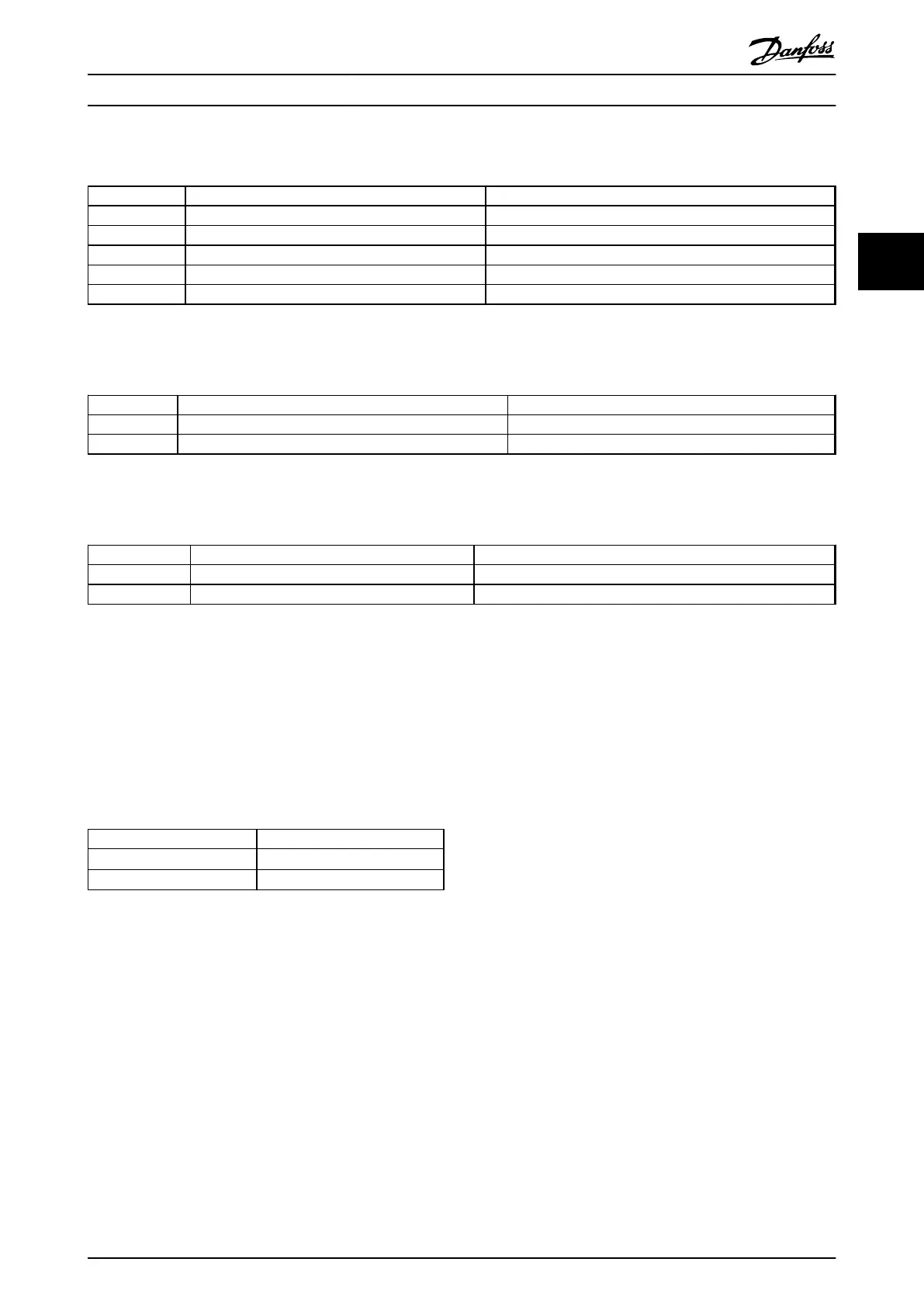

3.4.14 Motor Insulation

For motor cable lengths ≤ the maximum cable length, the

motor insulation ratings listed in Table 3.12 are

recommended. The peak voltage can be twice the DC-link

voltage or 2.8 times mains voltage, due to transmission

line effects in the motor cable. If a motor has lower

insulation rating, use a dU/dt or sine wave filter.

Nominal Mains Voltage Motor Insulation

U

N

≤ 420 V

Standard U

LL

= 1,300 V

420 V < U

N

≤ 500 V Reinforced U

LL

= 1,600 V

Table 3.12 Recommended Motor Insulation Ratings

3.4.15

Motor Bearing Currents

Motors with a rating 110 kW or higher combined with

frequency converters are best with NDE (Non-Drive End)

insulated bearings to eliminate circulating bearing currents

caused by motor size. To minimise DE (Drive End) bearing

and shaft currents, proper grounding is required for:

•

Frequency converter

•

Motor

•

Motor-driven machine

•

Motor to the driven machine

Although failure due to bearing currents is infrequent, use

the following strategies to reduce the likelihood:

•

Use an insulated bearing

•

Apply rigorous installation procedures

•

Ensure that the motor and load motor are

aligned

•

Strictly follow the EMC Installation guideline

•

Reinforce the PE so the high frequency

impedance is lower in the PE than the input

power leads

•

Provide a good high frequency connection

between the motor and the frequency converter

•

Ensure that the impedance from frequency

converter to building ground is lower than the

grounding impedance of the machine. Make a

direct ground connection between the motor and

load motor.

•

Apply conductive lubrication

•

Try to ensure that the line voltage is balanced to

ground.

•

Use an insulated bearing as recommended by the

motor manufacturer (note: Motors from reputable

manufacturers typically have insulated bearings

as standard in motors of this size)

Installation Operating Instructions

MG37A202 Danfoss A/S © Rev. 2014-07-29 All rights reserved. 29

3 3

Loading...

Loading...