3 Installation

3.1 Installation Site Checklist

3.1.1 Planning the Installation Site

Select the best possible operation site by considering the

following (see details on the following pages, and in the

Design Guide):

•

Ambient operating temperature

•

Installation method

•

Cooling

•

Position of the unit

•

Cable routing

•

Voltage and current supply from power source

•

Current rating within range

•

Fuse ratings if not using built-in fuses

3.2 Equipment Pre-Installation Checklist

•

Before unpacking the frequency converter,

examine the packaging for signs of damage. If

the unit is damaged, refuse delivery and

immediately contact the shipping company to

claim the damage.

•

Before unpacking the frequency converter, locate

it as close as possible to the final installation site

•

Compare the model number on the nameplate to

what was ordered to verify the proper equipment

•

Ensure each of the following are rated for the

same voltage:

-

Mains (power)

-

Frequency converter

-

Motor

•

Ensure the output current rating is equal to or

greater than the motor full load current for peak

motor performance.

-

Motor size and frequency converter

power must match for proper overload

protection.

-

If frequency converter rating is less than

that of the motor, full motor output is

impossible.

3.3 Mechanical Installation

3.3.1 Cooling and Airflow

Cooling

Cooling can be obtained in different ways, by using the

cooling ducts in the bottom and the top of the unit, by

taking air in and out the back of the unit or by combining

the cooling possibilities.

Back cooling

The backchannel air can also be ventilated in and out the

back of a Rittal TS8 enclosure for frame size F18 LHD. This

offers a solution where the backchannel could take air

from outside the facility and return the heat losses outside

the facility thus reducing air-conditioning requirements.

NOTICE

A door fan(s) is required on the enclosure to remove the

heat losses not contained in the backchannel of the

drive and any additional losses generated from other

components installed inside the enclosure. The total

required air flow must be calculated so that the

appropriate fans can be selected. Some enclosure

manufacturers offer software for performing the

calculations (i.e. Rittal Therm software).

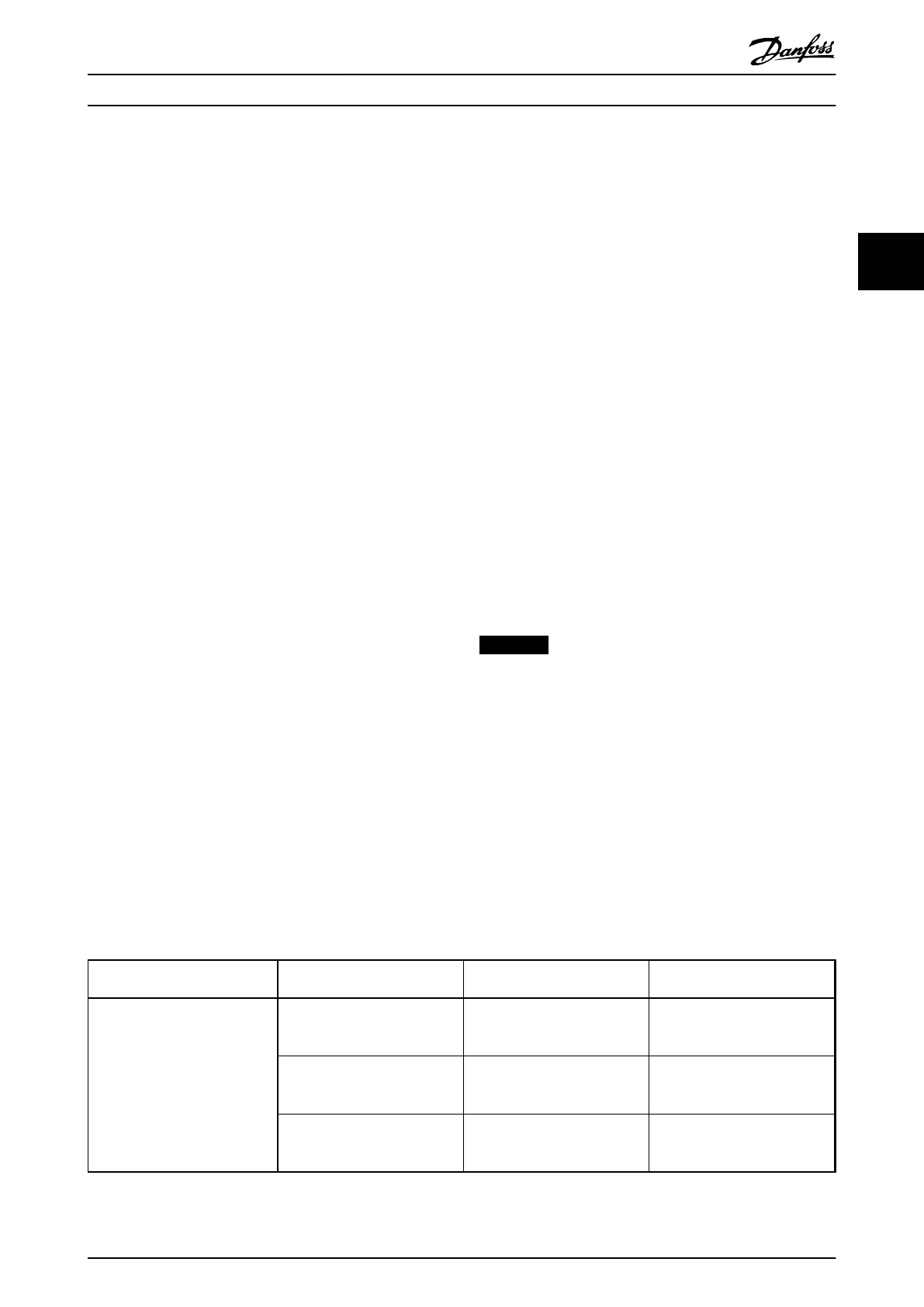

Airflow

The necessary airflow over the heat sink must be secured.

The flow rate is shown in Table 3.1.

Enclosure protection Frame size

Door fan/top fan airflow

Total airflow of multiple fans

Heat sink fan

Total airflow for multiple fans

IP21/NEMA 1

IP54/NEMA 12

D13 P160–P250

(LHD120)

3 door fans, 510 m

3

/h (300 cfm)

(2+1, 3x170=510)

2 heat sink fans, 1530 m

3

/h (900

cfm)

(1+1, 2x765=1530)

E9 P315–P400

(LHD210)

4 door fans, 680 m

3

/h (400 cfm)

(2+2, 4x170=680)

2 heat sink fans, 2675 m

3

/h

(1574 cfm)

(1+1, 1230+1445=2675)

F18 P500–P710

(LHD330)

6 door fans, 3150 m

3

/h (1854

cfm)

(6x525=3150)

5 heat sink fans, 4485 m

3

/h

(2639 cfm)

2+1+2, ((2x765)+(3x985)=4485)

Table 3.1 Heat Sink Air Flow

Installation Operating Instructions

MG37A202 Danfoss A/S © Rev. 2014-07-29 All rights reserved. 15

3 3

Loading...

Loading...