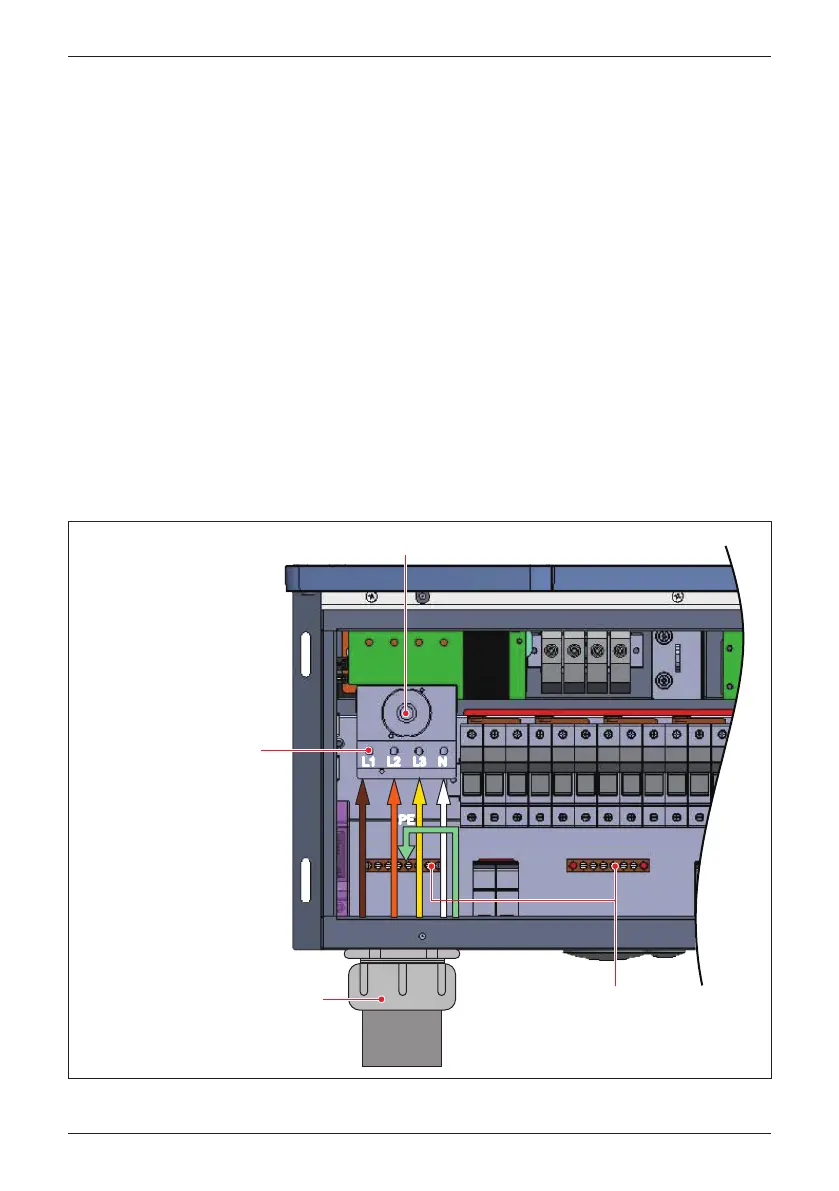

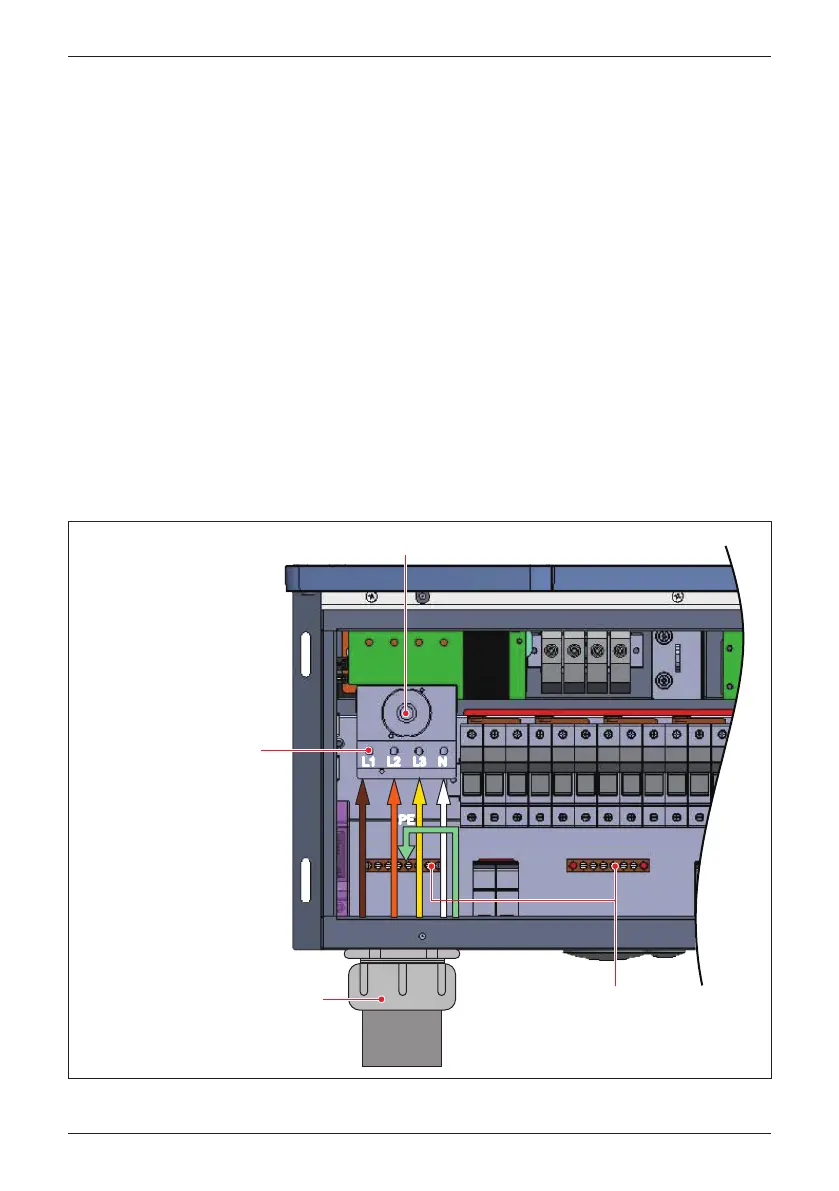

Figure 3-19 illustrates the location of the AC conduit entry and connections and

AC terminal block: for 120 models.

Ensure the AC conductors used are sized to the correct ampacity per NEC or

other local code. Refer to Figure 3-17.

- Open all AC switch cage-clamps as noted in Section 3.3.4.

- Insert stripped phase conductor into appropriate switch terminal.

- Tighten each phase terminal lug to a torque value of 31 lbf-in (3.5 N•m).

- Loosen screw in one of the locations on the ground bar located on the rear wall

of the WB chassis.

- There are two options for connecting the PE conduit to the model 120 inverter:

• Insert the EGC (6~4 AWG) into the ground bar and tighten the lugin the

ground bar lug to a torque value of 26 lbf-in (3 N•m). (see Figure 3-19)

• Insert the EGC (1~2/0 AWG) into the grounding screw terminal, torque value

of 80 lbf-in (9 N•m). (see Figure 3-20)

3.3.5 AC Wiring for M80/60U_120 models

Figure 3-19: Two optional Location of AC terminals and wiring (120 model)

After inserting

conductor, torque

terminal screw to

31 lbf-in (3.5 N•m)

After inserting conductor,

torque terminal screw to 26 lbf-in (3 N•m)

Allowable PE conductor

size 6~4 AWG (14~22mm²)

AC switch

L3L2L1

AC chassis entry accommodates

up to 2" trade size conduit

(e.g., EMT)

EMT

NN

PE

PE

42

Installation

Loading...

Loading...