Chapter 4 Parameters

VFD-EL-W

4-39

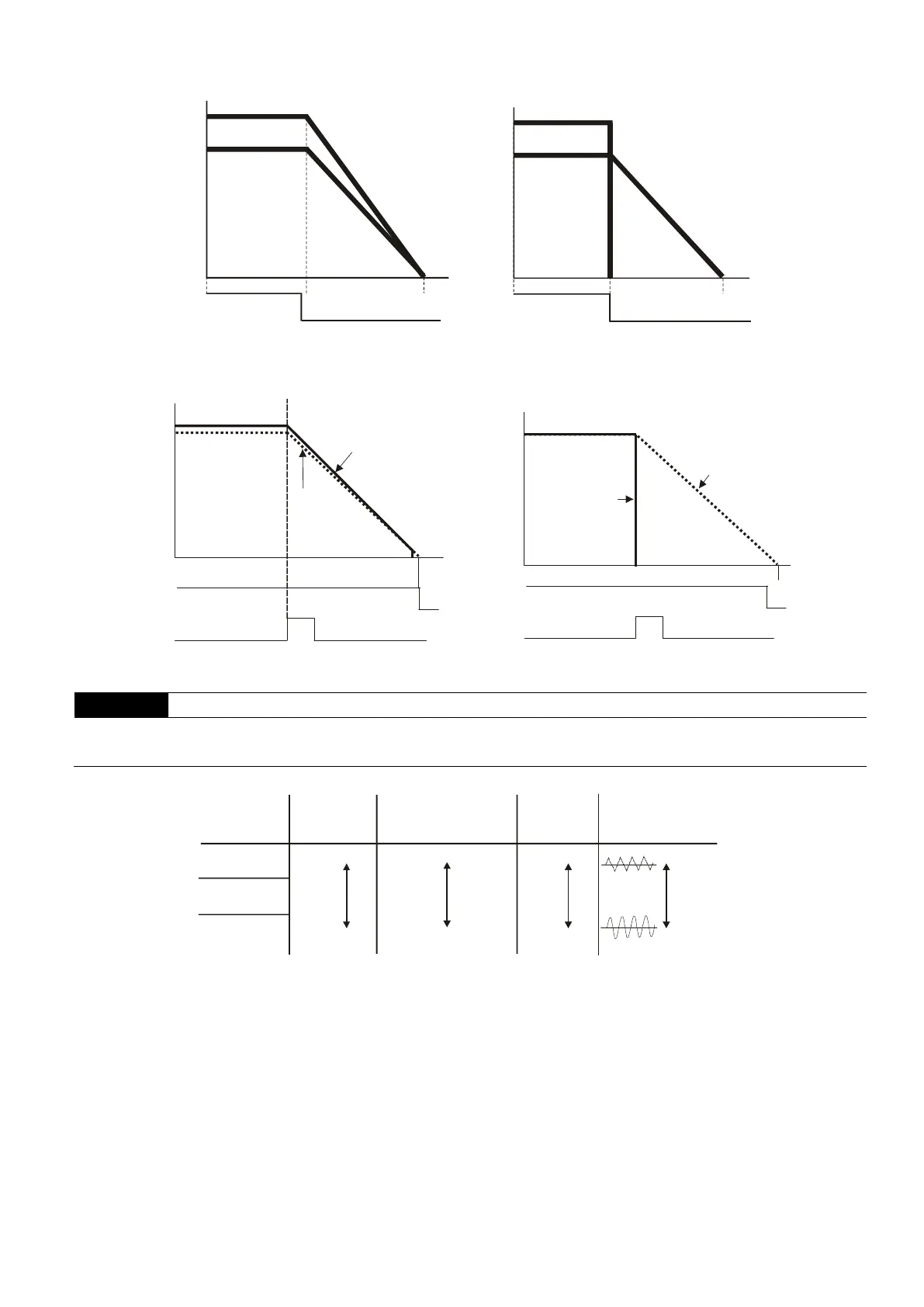

Example uses are blowers, punching machines, centrifuges and pumps.

RUN

STOP

Frequency

Time

Time

output

frequency

output

frequency

motor

speed

motor

speed

operation

command

operation

command

stops according to

decel eration time

free run to stop

ramp to stop and free run to stop

EF

frequency output

motor

speed

EF

operation

command

stops according to

decel eration time

When Pr.02.02 is set to 2 or 3

frequency

output

free run to stop

operation

command

When Pr.02.02 is set to 0 or 1

motor

speed

02.03

PWM Carrier Frequency Selection Unit: 1

Default: 8

Settings 2–12 kHz

Determines the PWM carrier frequency of the AC motor drive.

2kHz

8kHz

12kHz

Carrier

Noise

Noise or leakage

current

Heat

Dissipation

Current

Wave

Significant

Minimal

Significant

Minimal

Minimal

Significant

Minimal

Significant

From the table, you can see that the PWM carrier frequency has a significant influence on the electromagnetic

noise, AC motor drive heat dissipation, and motor acoustic noise. The PWM carrier frequency is decreased

automatically according to the ambient temperature and output current of the AC motor drives. It is used to

prevent the AC motor drive from overheating and thus extend the IGBT’s life. Increasing the PWM carrier

frequency may reduce the noise of motor operation, but interference measures have to be taken for the

consideration of overall wiring.