Item Details

External detector 3

Note Gx-IC10/Gx-OEM Only.

Use product detect sensor 3.

External detector 4

Note Gx-IC10/Gx-OEM Only.

Use product detect sensor 4.

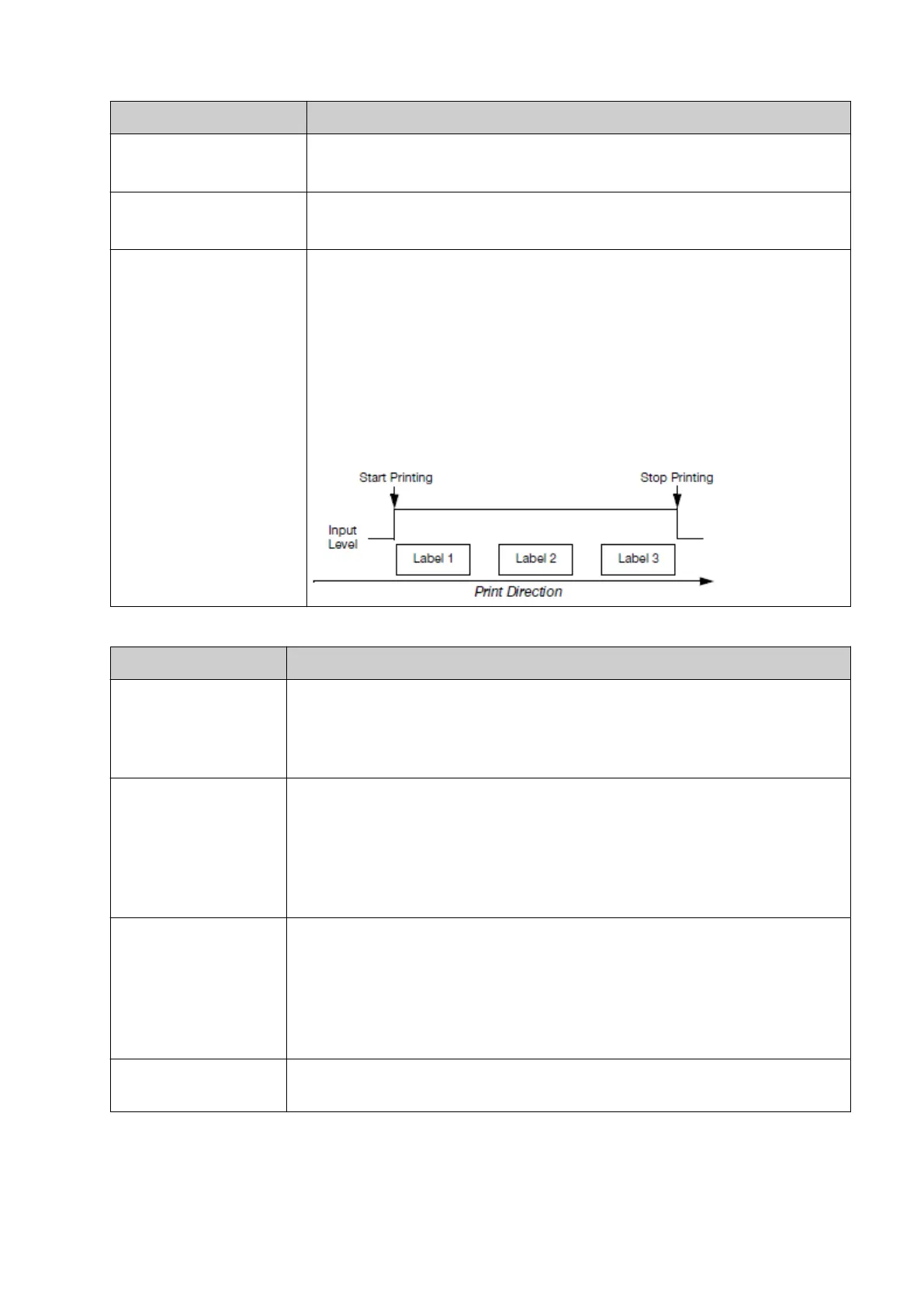

GPI Use an input connected to one of the controller's I/O inputs to

continuously print a label. To use this feature, the I/O input must be

set to "Print enable", see I/O Function Assignment on page 82.

While the input is held activate and product movement is detected,

the print group will print continuously until product movement stops

or the input is deactivated.

Note

The labels Forward oset and Reverse oset settings

define the space between each label, see Label

Defaults on page 101.

6.

The print trigger settings described below can also be viewed and setup:

Item Details

Active level

Note If "External trigger capture" is set to GPI, this setting is

defined in the "I/O" settings, see I/O Function Assignment

on page 82.

Select if a High or Low input signal will trigger a print.

Current level

Note If "External trigger capture" is set to GPI, this setting is

shown in the "I/O" settings, see I/O Function Assignment

on page 82.

Displays the current state of the connected product detect sensor. This

allows the user to check if the product detect sensor is setup and

working correctly.

Product detect

persistence (ms)

If "External trigger capture" is set to GPI, this setting is defined by "Filter

(ms)" in the "I/O" settings, see I/O Function Assignment on page 82.

Set this value as low as possible. If a high value is set, the accuracy of

the print trigger will be aected.

Select how long the product detect signal must be active, for the signal

to be recognised as valid.

Distance to check PD

signal (mm)

If no print trigger signal is received, after the production line has moved

by the distance set in this setting, a warning will be displayed.

INSTALLATION

EPT053091 - Issue 5 - 07 May 2021 80

Loading...

Loading...