DE08TS Diesel Engines Maintenance

c. Tappet and push rod

• Clearance

Measure the clearance of the tappet and tappet

holes of the cylinder block. If the value is beyond the

specified limit, replace tappets.

• Visual check of tappet

Visually check the face of the tappets in contact with

the cam for pitting, scores or cracks, and replace if

severely damaged. If the amount of cracks or pitting

is small, correct with an oil stone or grinding paper.

• Outside diameter of tappet

With an outside micrometer, measure the tappet out-

side diameter If the measured value is beyond the

limit, replace tappets.

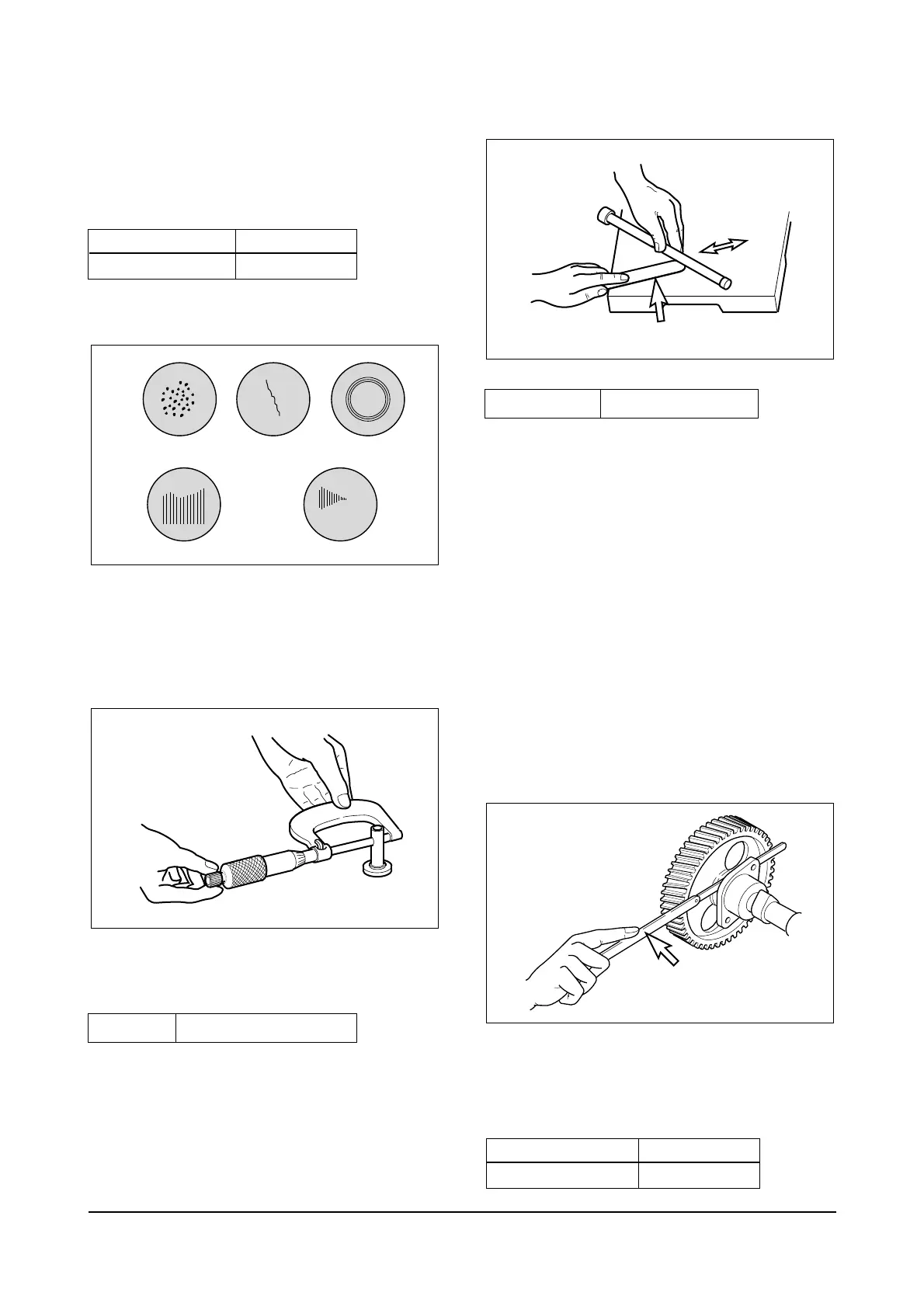

• Push rod run-out

Use a feeler gauge to measure the push rod run-out.

Roll the push rod along a smooth flat surface as

shown in the figure.

d. Reassembling rocker arm assembly

Reassembling can be done in the reverse order of

disassembling and following things should be heed-

ed

• Check the oil supply hole of rocker arm shaft for

any clog and clean thoroughly.

• Be careful not to occur any swap of position and

reverse assembly.

Camshaft

1. Camshaft end play

• Push the thrust plate toward the cam gear

• With a feeler gauge, measure the clearance

between the thrust plate and camshaft journal.

• If the end play is excessive, replace the thrust

plate.

EA0M4073

Feeler gauge

EDM2061I

EA0M4070

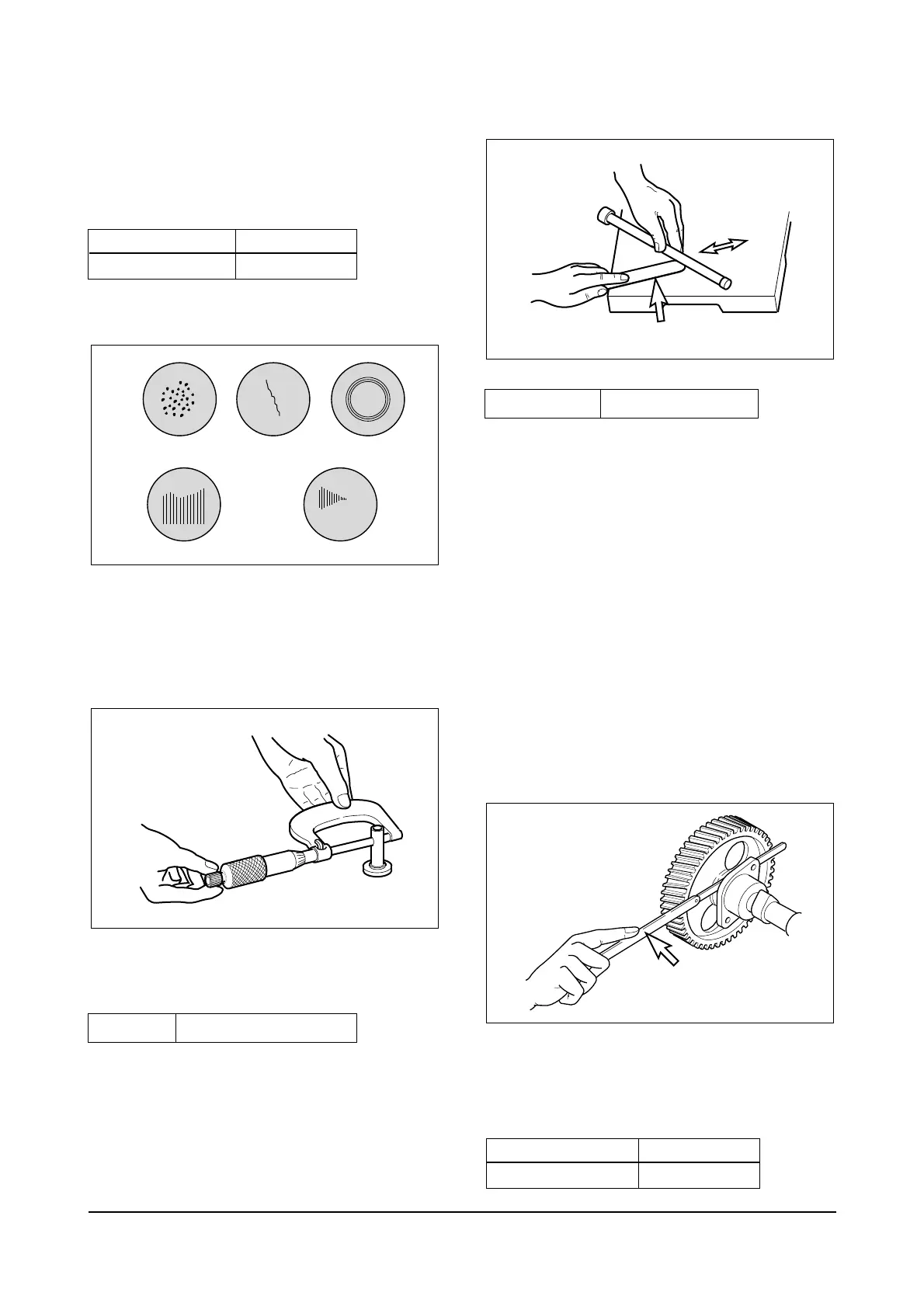

(1) Unevenness

(4) Abnormal

(2) Crack (3) Normal

42

Standard Limit

0.035 ~ 0.077 mm 0.15 mm

Standard

N

19.944 ~

N

19.965 mm

Limit 0.3 mm or less

Standard Limit

0.28~ 0.43 mm 0.6 mm

Loading...

Loading...